Seed firmer adjustments, Keeton seed firmer adjustment – Great Plains YP1220 Operator Manual User Manual

Page 51

Great Plains Manufacturing, Inc.

Adjustments

47

03/14/2012

401-506M

Refer to Figure 54

Note: With the seed meter wheel removed, you may want

to check the meter for internal damage or trash.

Note: Some wear on top edge of slide

is normal. Ex-

cess wear is cause for replacement.

6.

When changing crops be sure to clean out air sys-

tem before installing new meters or wheels. “Clean-

ing Out Air System” on page 59.

Note: When installing a seed wheel that requires Flow

Gate, also remove the meter slide. If replacing a

rice wheel with another seed wheel, re-install the

meter slide. See page 58.

7.

Place new wheel on meter wheel shaft. Seat wheel

fully on cross-pin.

8.

Replace spring-loaded wheel retainer. Make

1

⁄

4

turn

to seat cross-pin in shallow groove of retainer.

Seed Firmer Adjustments

20 Series row units include a seed flap, and accept one

of two optional firmers.

Sharp Object Hazard:

Row unit disk blades may be sharp. Use caution when making

adjustments. To adjust the Keeton Firmer, lower the planter

until the disks of the row units are resting on the ground.

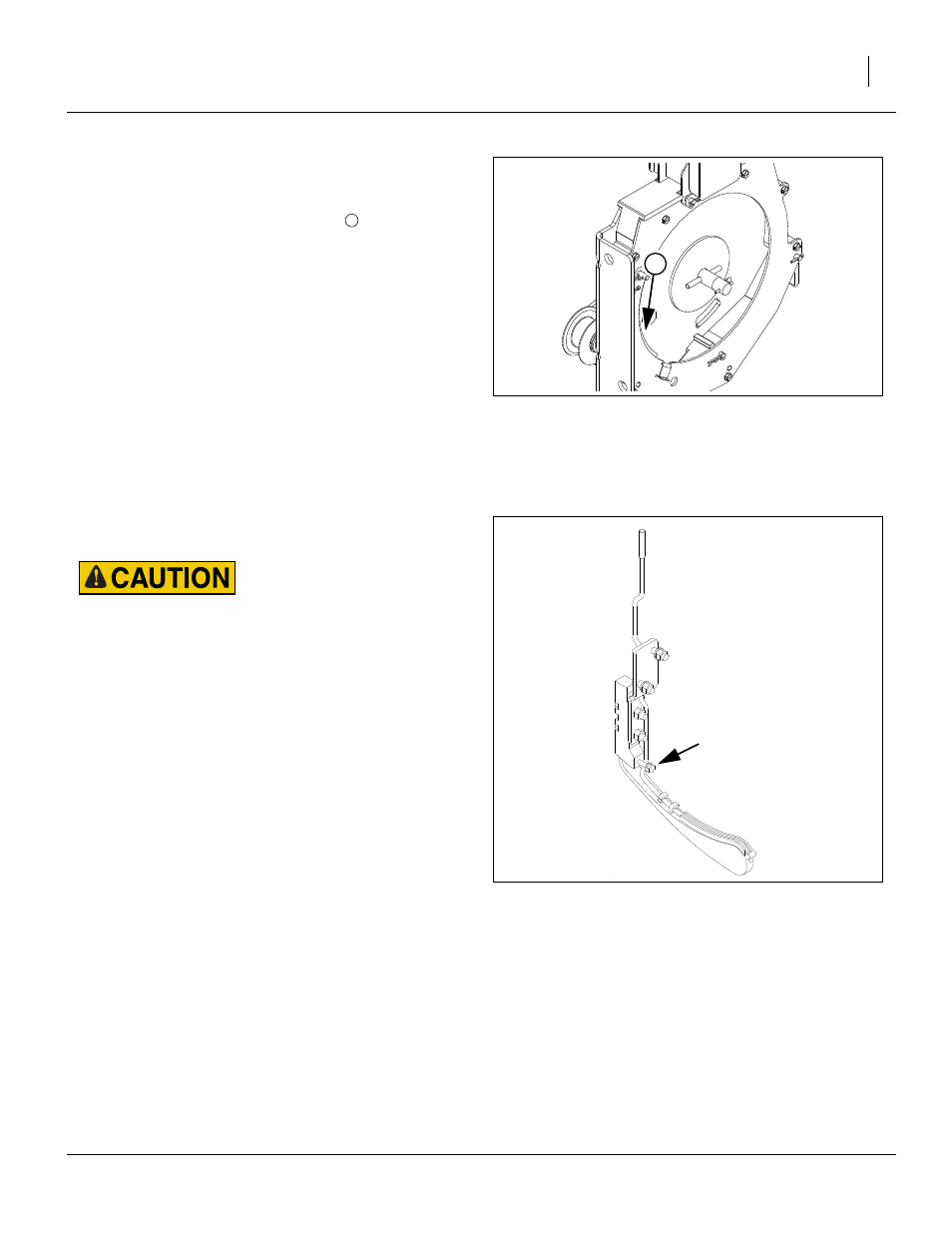

Keeton Seed Firmer Adjustment

The optional Keeton Seed Firmer is an engineered poly-

mer shape that slides down the seed trench. It traps

seeds as they exit the seed tube and firms them into the

bottom of the furrow.

Refer to Figure 55

The Firmer is provided with a preset tension which is rec-

ommended for using the first year. The tension screw

can

➂

be tightened in subsequent years according to

your needs. Firmers should provide just enough tension

to push seeds to the bottom of the trench.

Measure the distance from the ground to the head of the

tension screw. This distance should be 4 to 4

1

⁄

2

in. If not,

loosen the bolts in the mounting bracket and select differ-

ent holes until the proper measurement is attained.

Figure 54

Inspect Meter

27462

1

1

Figure 55

Keeton Seed Firmer

20327

➂