Field operation, Seed hopper sensor – Great Plains YP1220 Operator Manual User Manual

Page 33

Great Plains Manufacturing, Inc.

Operating Instructions

29

03/14/2012

401-506M

Field Operation

1.

Hitch planter to a suitable tractor. See “Hitching

Tractor to Planter” on page 15.

2.

Make sure proper meter wheels are in place.

3.

Make sure all seed meter clean out doors are closed.

See “Cleaning Out Meters” on page 56.

4.

Set planting rate. See “Planting Rate” on page 38.

5.

Set tractor 3-point hitch control for depth control

operation - not load control.

Note: If tractor 3-point hitch control is set for load control,

hitch movement may cause changes in row unit

depth resulting in uneven depth control.

6.

Set tongue height with planter lowered, to 46in. See

“Leveling Frame Side-to-Side” on page 17.

7.

Turn on fan. Set tractor hydraulic flow control to

obtain the rpm from the table below, as indicated on

system monitor.

Note: Refer to page 33 for further information.

8.

Pull forward, lower planter, and begin planting.

9.

Always lift planter out of ground when turning at row

ends and for other short-radius turns. Planting will

stop automatically as planter is raised.

10. Use tractor hydraulics to raise/lower planter, not trac-

tor 3-point.

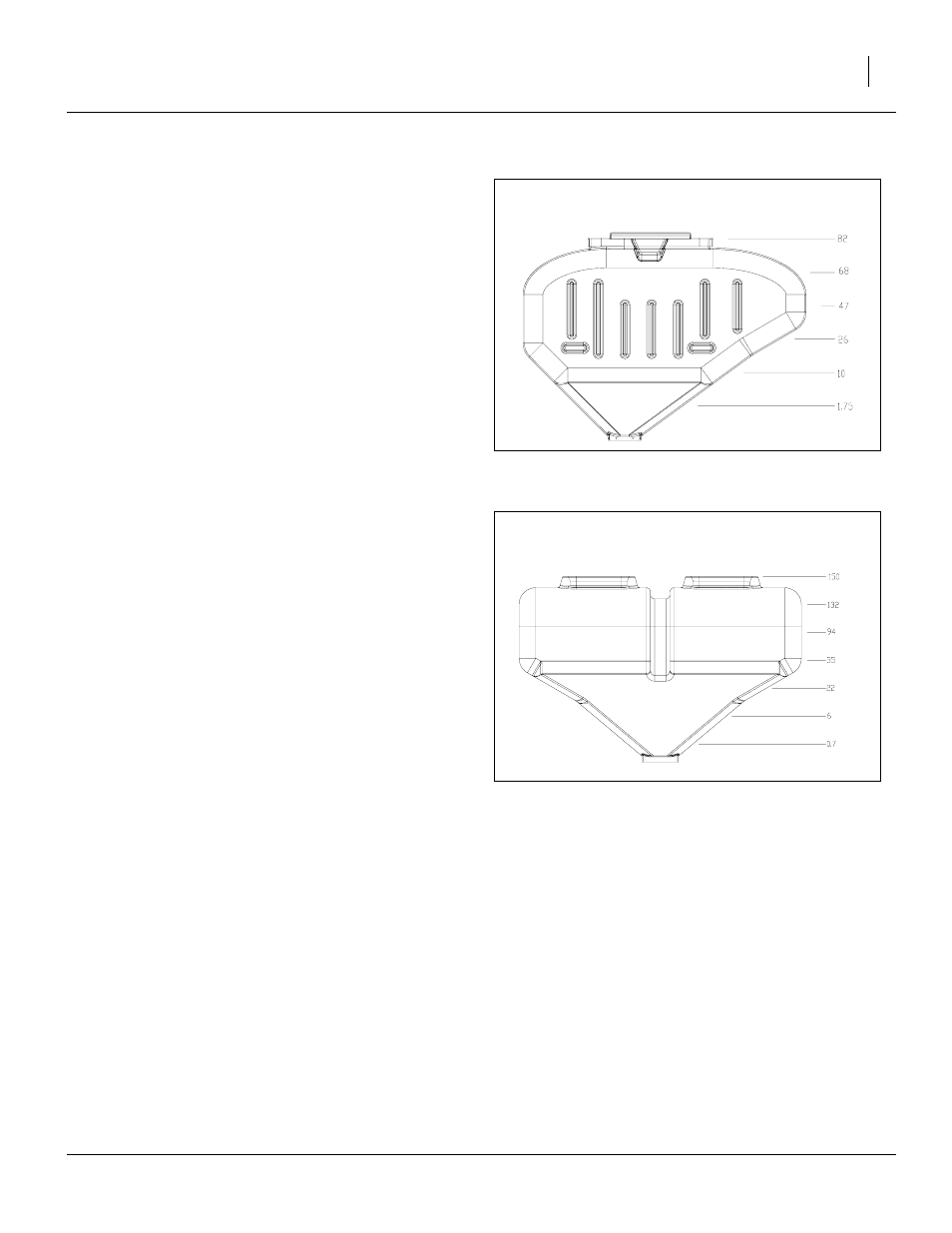

Seed Hopper Sensor

Refer to Figure 28 and Figure 29

For planters equipped with optional 82 bu. or 150 bu.

hoppers, an extra level sensor is included. Use Figure 28

or Figure 29, showing capacity, to place it at the level that

suits your operation. Disconnect sensor in manifold and

attach lead to this sensor to use it.

3800 rpm using 82bu or 150bu hoppers

3500 rpm using bulk seed boxes

Figure 28

82 Bu Bulk Hopper

22958

Approximate capacity (in bu) of

82bu hopper, at 10in increments

Figure 29

150 Bu Bulk Hopper

22958

Approximate capacity (in bu) of

150bu hopper, at 10in increments