Marker speed, Marker chain length, Marker speed marker chain length – Great Plains 3N4010HDA Operator Manual User Manual

Page 66

62

3N-4010HDA

Great Plains Manufacturing, Inc.

196-444M

2013-09-24

Marker Speed

The procedure for adjusting marker speed is different for

single marker with needle valve and dual markers with

sequence valve.

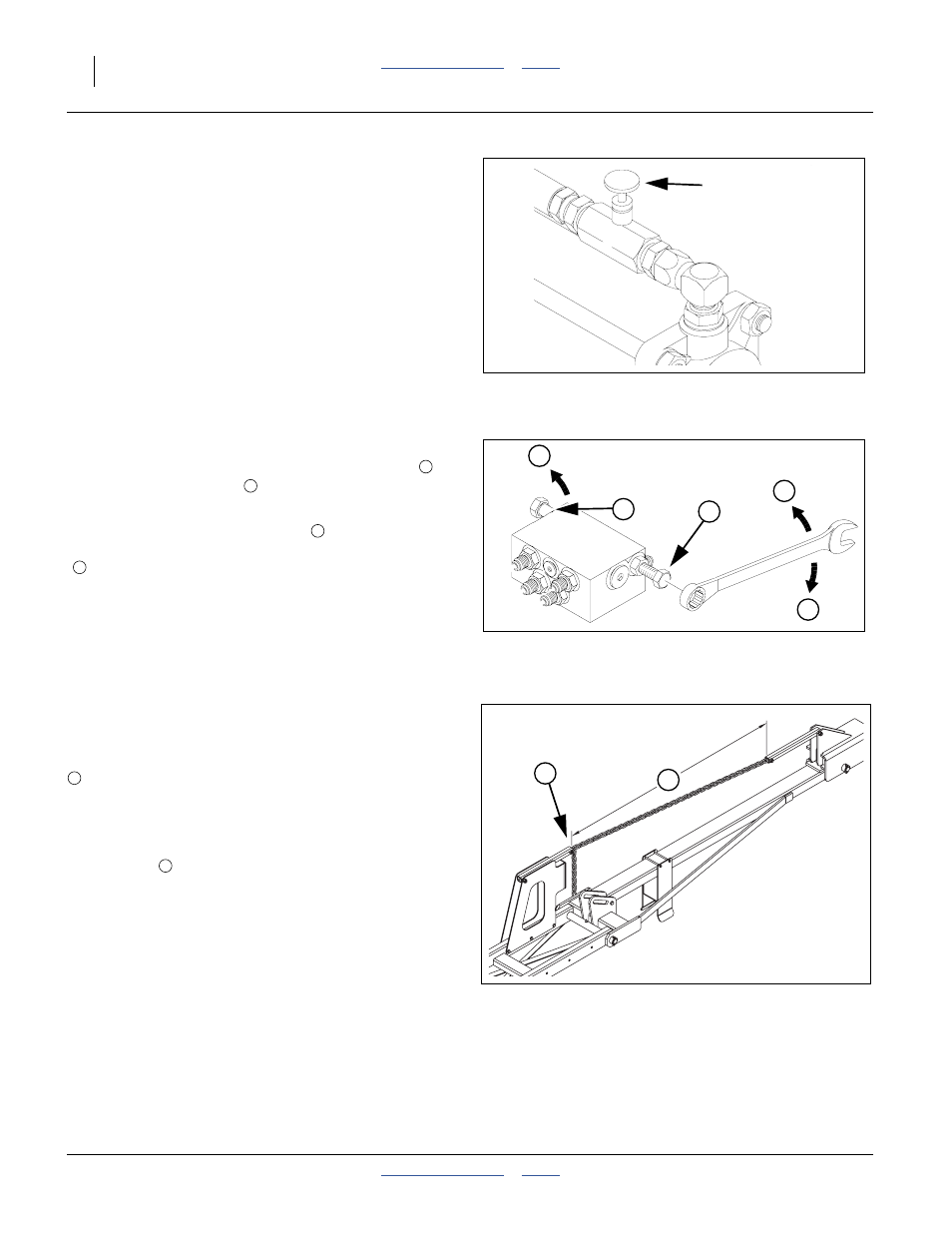

Single Marker/Needle Valve Speed

Refer to Figure 61

A needle valve controls the folding speed. The needle

valve is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Turn adjustment knob

clockwise to reduce folding speed or counterclockwise to

increase folding speed. Excessive folding speed could

damage markers and void the warranty.

Dual-Marker/Sequence Valve Speed

There is one adjustment screw for unfolding speed

and one for folding speed

. You can identify adjustment

screws by markings stamped in valve body.

Turn adjustment screws clockwise (

: slower) to

decrease [un]folding speed and counterclockwise

(

: faster) to increase [un]folding speed.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Excessive [un]folding

speed could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

Marker Chain Length

Refer to Figure 63

With marker unfolded, adjust chain to a length

of 67in (170cm)

Slowly fold marker while observing disk. If marker disk

slides across the ground more than a foot (0.3m) before

chain and linkage lifts it up, the chain is too long.

Remove bolt

and shorten chain one or two links.

Check adjustment by repeating folding process.

If chain is too short when marker is unfolded, it will

prevent the marker blade from dropping into field

depressions, causing skips in the mark line. Correct this

condition by lengthening chain one or two links.

Figure 61

Needle valve Adjustment

15625

1

2

F

S

S

Figure 62

Sequence Valve Adjustment

14048

1

2

S

F

Figure 63

Marker Chain Length

18962

1

2

1

2