Tongue spacer block – Great Plains 3N4010HDA Operator Manual User Manual

Page 63

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

59

2013-09-24

196-444M

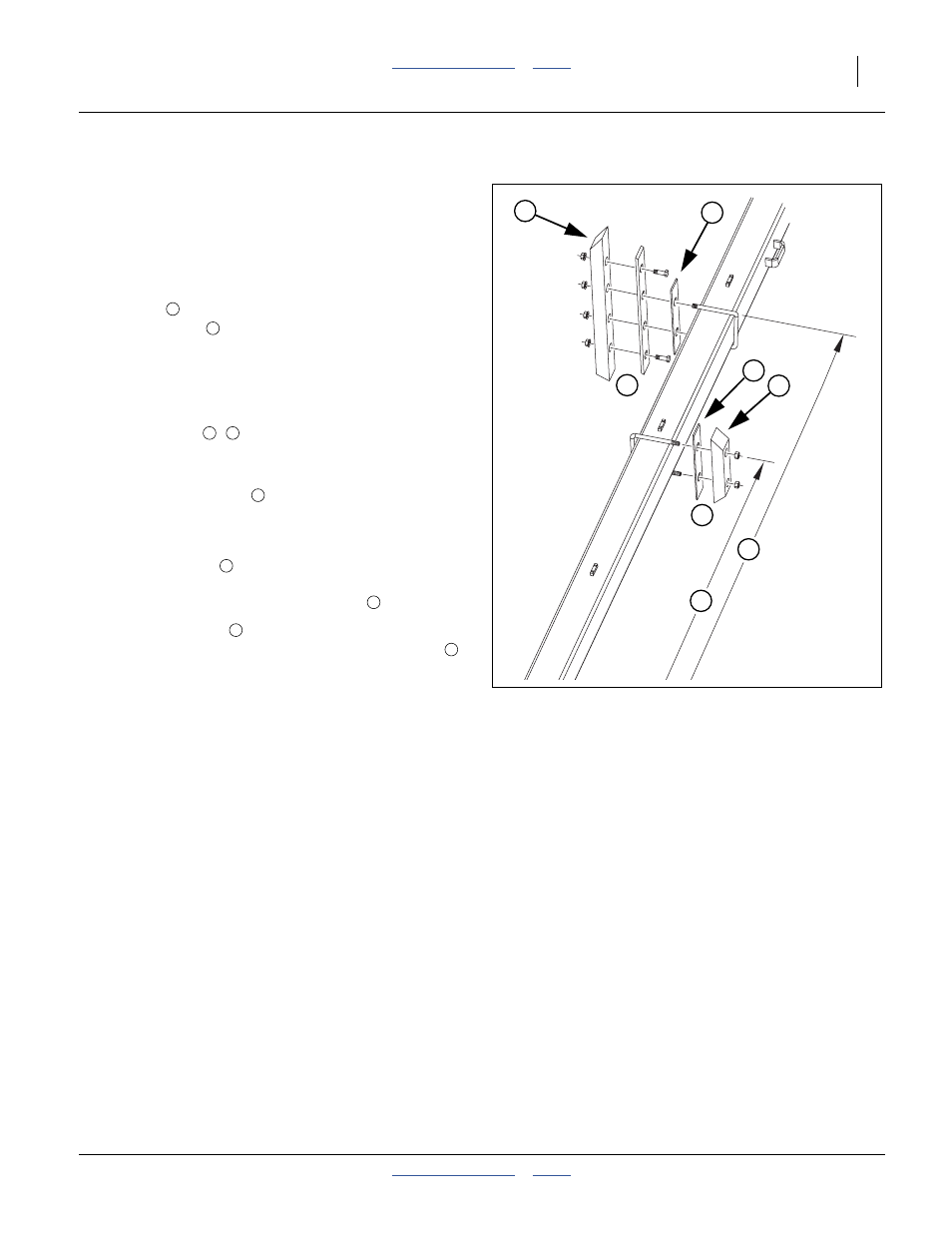

Tongue Spacer Block

If the folded drill does not pull straight, wanders back and

forth while being towed, or fails to latch during folding, it

may be necessary to replace or adjust one or more

tongue spacer block assemblies.

Refer to Figure 58 (which depicts right tongue tube)

There are four of these block assemblies on the drill

tongue. Two

are on the inside, and contact each other

when folding. Two

are on the outside, and contact the

wing main frames when folded.

The amount of contact should be just enough to prevent

sway, but not so much that it prevents reliable transport

latching during fold.

If the skid blocks (

,

) are worn or deformed, replace

them.

If the skid blocks are serviceable, and there is a gap

when folded, add a shim

. Consult the latest Parts

manual for the current shim part number.

When re-installing:

• The inside blocks

must be exactly opposite each

other, and are located 122in (3.1m) from the forward

end of the tongue tube wall (dimension

).

• The outside blocks

are located 155in (3.74m) from

the forward end of the tongue tube wall (dimension

).

Note: It is normal for the tongue assembly to rotate slight-

ly when the wings move up and down independent-

ly. Adjusting tongue shims does not eliminate this.

Figure 58

Tongue Spacer Blocks

20362

1

2

3

4

5

5

6

7

1

2

3

4

5

1

6

2

7