Great Plains 3N4010HDA Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

Adjustments

39

2013-09-24

196-444M

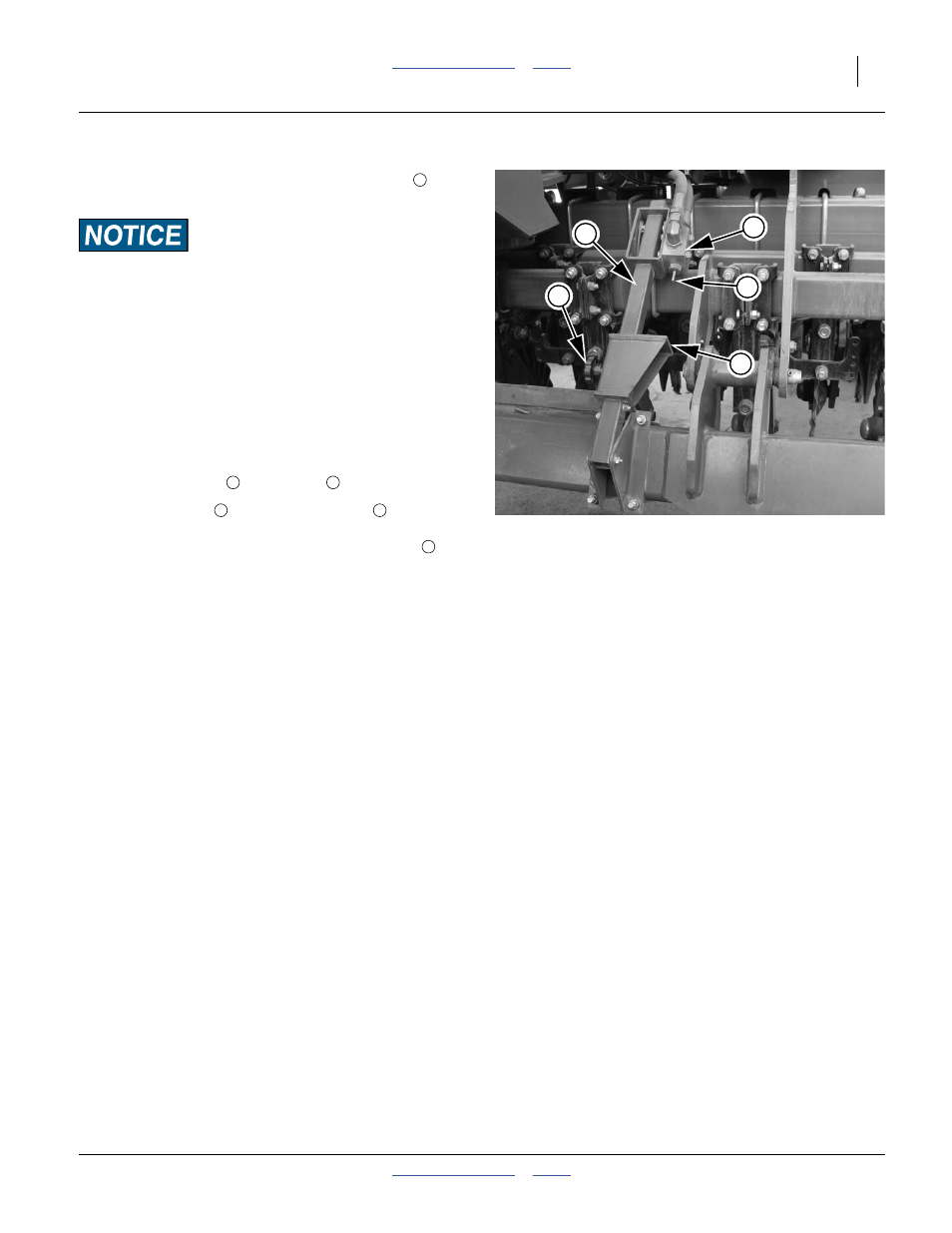

Refer to Figure 35

The lift system includes an adjustable stop valve

to fix

the height of the opener frame when the drill is lowered.

Make sure the drill is level and the lift system bled and

re-phased before adjusting the tool bar height.

To adjust the stop height:

1.

Move to smooth level ground representative of field

conditions.

2.

Lower the drill and measure the present tool bar

height. If the drill cannot be fully lowered due to row

unit spring settings, temporarily move the cams to a

lower setting, or out of notch entirely.

3.

Raise the drill.

4.

Loosen the knob

on the stop

.

5.

Adjust the stop

position on the tube

. Adjust up

(to raise) or down (to lower). Adjust by half the last

difference. Secure the stop with the knob bolt

.

6.

Lower the drill and measure the tool bar height. If the

error is more than about

1

⁄

8

in (3mm), repeat the

adjustment process from step 3.

7.

Raise and lower several times and confirm that the

drill stops consistently at the new height.

Note: It is important that all of the tires remain in contact

with the ground to maintain levelness of machine

from front to rear. Setting the depth control too

deep combined with high opener spring force can

cause the drill to tip forward when planting, which

may cause plugging.

Running with the front tires floating or skimming on

the ground will cause uneven coulter depth and

may cause uneven seed depth.

Figure 35

UMC/NC Opener Depth Stop

20274

2

3

1

4

5

1

2

3

3

4

2