Row unit down pressure – Great Plains 3N4010HDA Operator Manual User Manual

Page 48

44

3N-4010HDA

Great Plains Manufacturing, Inc.

196-444M

2013-09-24

Row Unit Down Pressure

Refer to Figure 42

The ideal amount of down-force causes the press wheels

to compress any loose surface soil, but not press a

trench into subsoil.

To assess down-force, operate the drill for a short

distance on typical ground (with or without seeding), and

stop. Leave the drill lowered (row units in ground).

At several row units, inspect the furrow created by the

opener discs and closed by the press wheels.

Note: Be sure to inspect rows both in and out of tire

tracks.

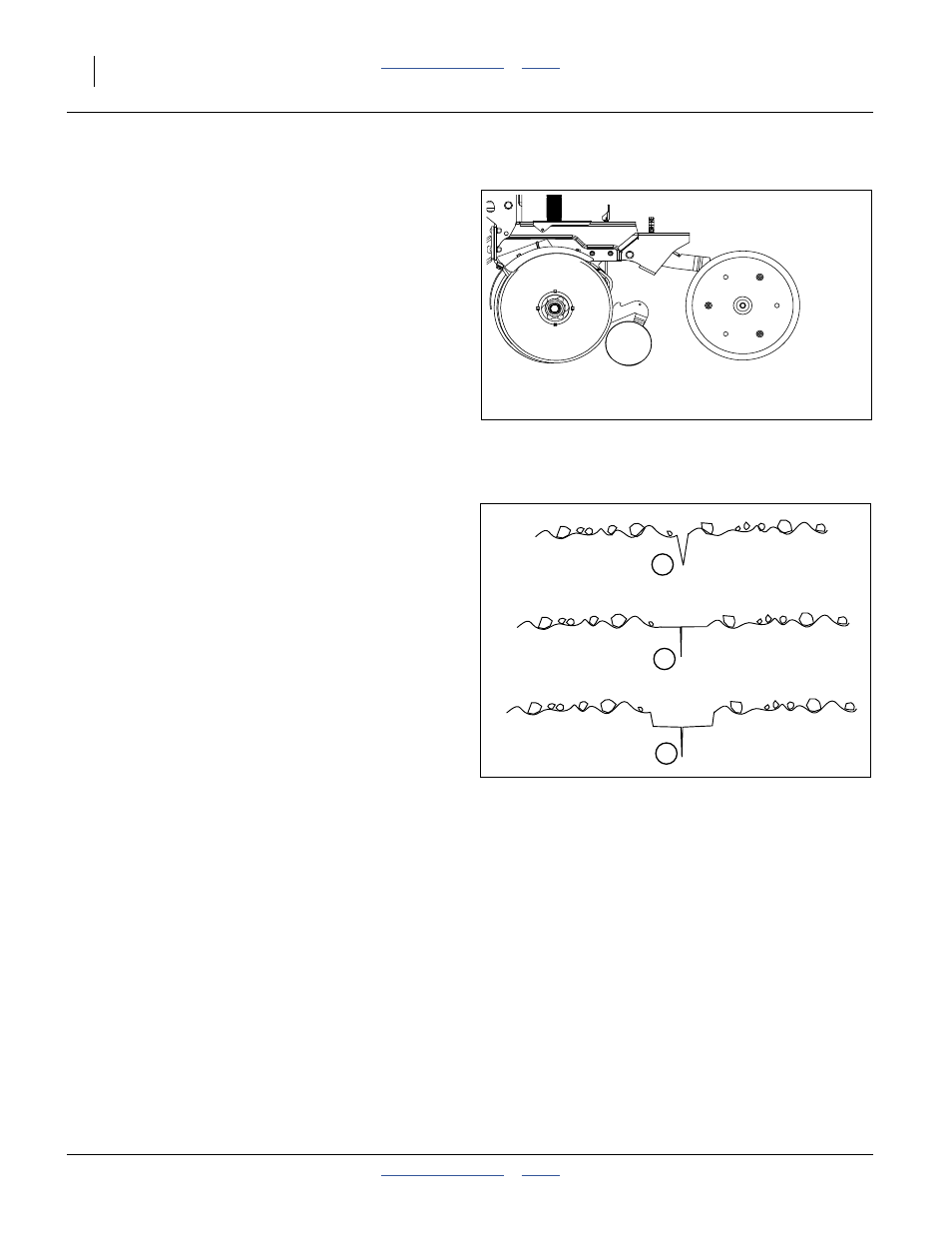

Refer to Figure 43

1.

If the press wheels are leaving no tracks, or light

tracks, increase down-force.

2.

If the wheels are compressing trash and loose soil,

and leaving clear tracks right at the top of the sub-

soil, down-force is probably correct and needs no

adjustment.

3.

If the wheels are creating a trench into the subsoil,

down-force is too high and needs to be reduced.

Adjusting Row Unit Down Force

The springs allow the row units to float down into

depressions and up over obstructions.

With Frame-Mounted Coulters

With frame-mounted coulters, the seed trench is

primarily opened by the coulters. Row unit springs

provide only additional assistance needed to make a

furrow “V” shaped and ensure furrow closure by the

press wheels.

Often, the rows may be run at the minimum spring

setting, other than in tire tracks, which commonly need

some adjustment.

If trench depth is not being achieved across all rows,

adjust the force and/or depth of the coulters before

making row unit spring adjustments.

With Unit-Mounted Coulters (or no coulters)

Without frame-mounted coulters, the row unit springs

provide the primary down force for cutting through

residue and opening the seed trench.

If you cannot achieve enough down force, adding a

weight kit may help. See “Frame Weights” on page 40.

Figure 42

Checking Furrow

27064

{

Inspect Furrow Here

Light or no press wheel

tracks

Insufficient down-force

Increase down-force

Press wheel(s) compress

loose soil only

Ideal

No adjustment required

Press wheel(s)

making deep tracks

Down-force too high

Reduce down-force

Figure 43

Assessing Down-force

1

2

3