Great Plains 3N4010HDA Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

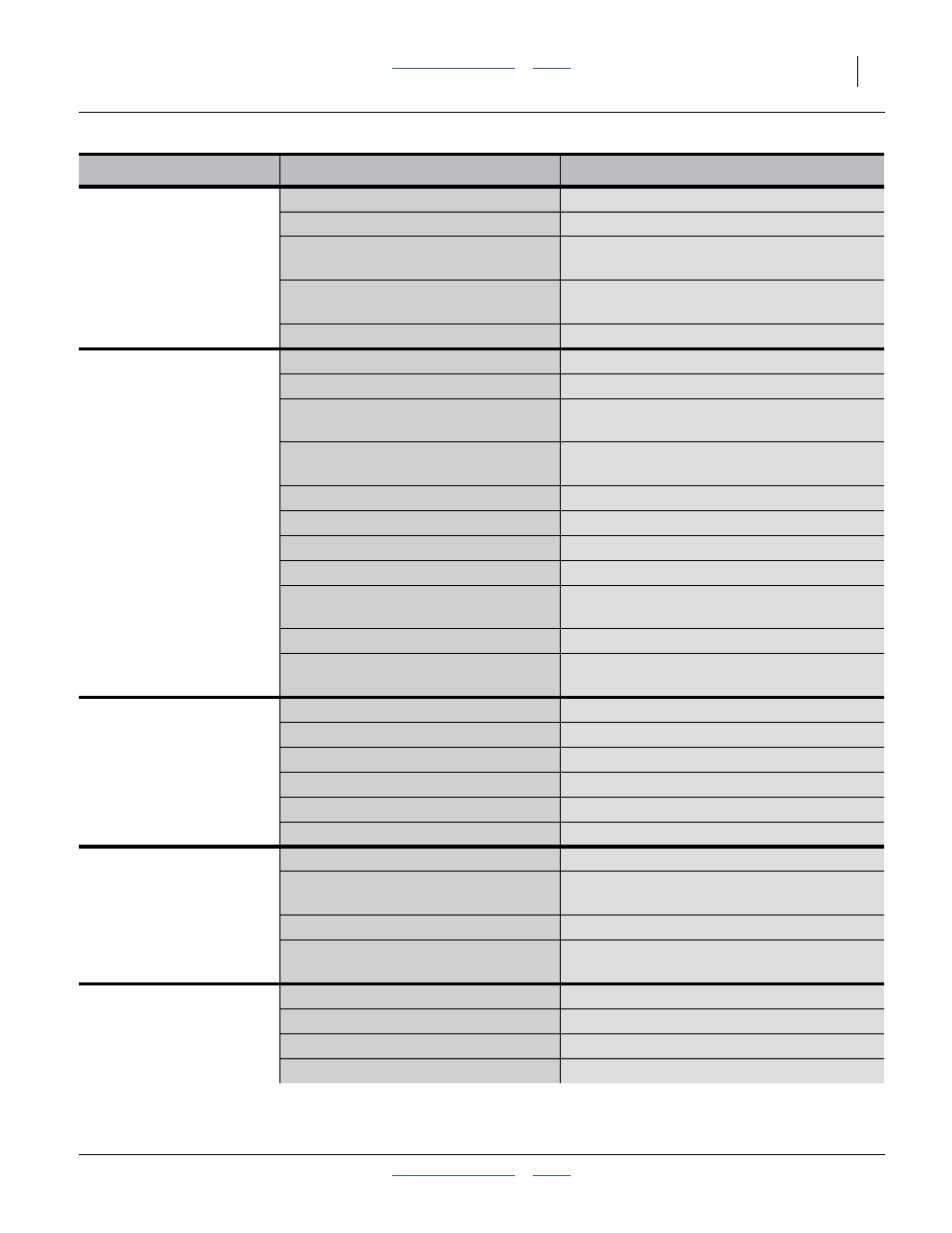

Troubleshooting

51

2013-09-24

196-444M

Uneven seed spacing

Seed-Lok plugging

Lock up Seed-Lok, page 47.

Damaged or missing seed flap

Replace seed flap.

Opener disks not turning.

See “Opener disks not turning freely” in this

Troubleshooting chart.

Gearbox setting too low

Operate variable rate gearboxes at scale set-

tings of 20 or higher for consistent results.

Fan speed too low

Check fan speed, page 29.

Uneven seed depth

Excessive field speed

Slow down.

Coulter depth adjustment

Verify coulter-to-opener relationship.

Coulter down-force insufficient -

coulters not achieving depth

Add weight or, if weight is sufficient, increase

coulter spring settings.

Insufficient opener down force for con-

ditions

Adjust row unit cam, page 45.

Conditions too wet

Wait for dryer weather.

Seed-Lok plugging

Lock up Seed-Lok, page 47.

Damaged or missing seed flap

Replace seed flap.

Damaged opener seed tube

Check for damage at tip of seed tube.

Partially plugged opener seed tube

Lift up drill, expose bottom of seed tube and

clean out.

Incorrect choice of coulter

Change coulter blade.

Skimming (gauge wheels skipping, or

off ground entirely)

Reduce coulter and/or row unit down forces,

or add weights.

Opener disks not turning

freely

Opener plugged with dirt

Clean opener. Adjust scraper.

Planting conditions too wet

Wait until drier weather.

Seed-Lok is plugging opener

Lock up Seed-Lok, page 47.

Too much blade-to-blade contact

Adjust disk contact. See page 46.

Failed disk bearings

Replace disk bearings.

Bent or twisted opener frame

Replace opener frame.

Press wheels not com-

pacting the soil as

desired

Too wet or cloddy

Wait until drier weather or rework ground.

Coulter set too shallow

Adjust coulter depth. See page 34 or

page 42.

Incorrect press wheel depth setting

Adjust T-handle. See page 48.

Opener spring pressure too low or too

high

Reduce opener spring pressure.

Excessive seed cracking

Excessive field speed

Slow down.

Unclean seed.

Use clean seed.

Damaged flute “stars” in air cart meter

Open calibration door and inspect flutes.

Damaged, old or dry seed

Use clean, new seed.

Problem

Cause

Solution