Marker adjustments, Marker disk adjustment – Great Plains 3N4010HDA Operator Manual User Manual

Page 53

Great Plains Manufacturing, Inc.

Adjustments

49

2013-09-24

196-444M

Marker Adjustments

This section covers marker items that may need

adjustment for current conditions, and assumes that the

markers are installed, set to the correct initial extension

and in proper working order. See also:

• “Marker Maintenance” on page 61

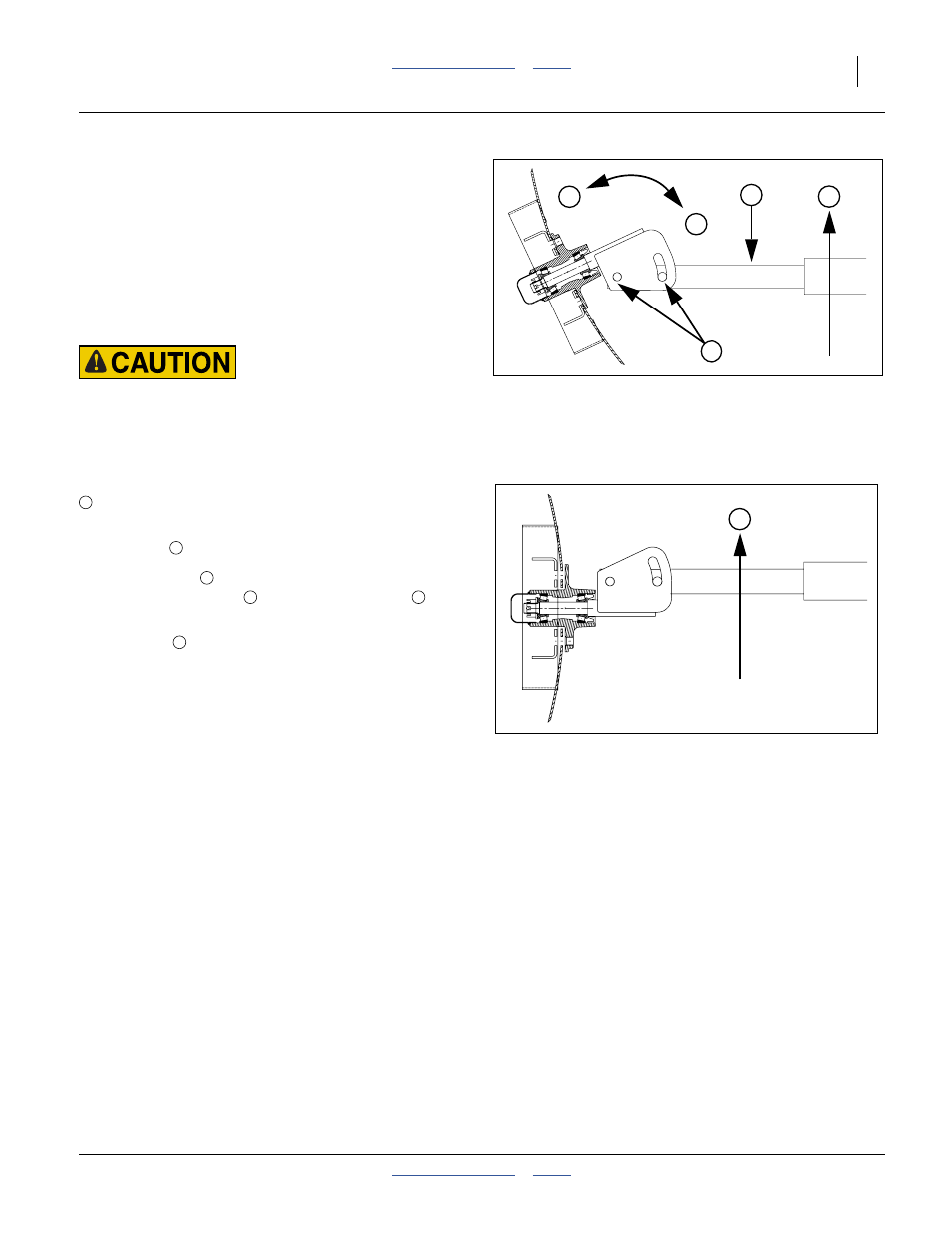

Marker Disk Adjustment

Sharp Object Hazard:

Marker disks may be sharp. Use caution when making

adjustments in this area.

Adjusting Mark Width

Refer to Figure 51

is the direction of travel.

To change angle of cut, and the width of the mark, loosen

1

⁄

2

-inch bolts

holding the disk assembly.

For a wider mark

, increase the angle of the marker

with respect to the tube

. For a narrower mark

,

reduce the angle.

Tighten bolts

.

Direction of Cut

Refer to Figure 52

To have the marker throw dirt out, invert the disk on the

spindle, and invert the disk assembly.

Figure 51

Marker Disk Angle

11757

T

2

1

N

W

T

Figure 52

Marker Disk Inverted

11248

T

T

2

W

1

N

2

- 1200 Parts Manual (210 pages)

- 706NT Material Rate (46 pages)

- 706NT Material Rate (50 pages)

- 2N-2410 Operator Manual (56 pages)

- 2N-2410 Operator Manual (48 pages)

- 12 Series Drills Assembly Instructions (6 pages)

- X-PresS 2006 Assembly Instructions (50 pages)

- TM500 Operator Manual (62 pages)

- 2010HDP Operator Manual (166 pages)

- YP1630F Material Rate (42 pages)

- YP2425 Operator Manual (162 pages)

- 3S-5000 Operator Manual (94 pages)

- 3PYP Operator Manual (188 pages)

- 3N-3010P Assembly Instructions (2 pages)

- 3N-3010 Assembly Instructions (9 pages)

- 3N-3010P Assembly Instructions (9 pages)

- PFH-15 Predelivery Manual (23 pages)

- PFH-15 Operator Manual (46 pages)

- PFH-15 Operator Manual (26 pages)

- P15126 Serial No 12724 (34 pages)

- DVN 8321 Operator Manual (38 pages)

- 3P500 Assembly Instructions (22 pages)

- 605NT Assembly Instructions (4 pages)

- 3P600 Assembly Instructions (12 pages)

- 605NT Assembly Instructions (8 pages)

- CPH-12 Assembly Instructions (3 pages)

- YP1625A-2420 24 Row 20-Inch Quick Start (6 pages)

- 8323 FCF Predelivery Manual (124 pages)

- P13937 (20 pages)

- 3323 DH Parts Manual (114 pages)

- YP3025-1820 25 Series 18 Row 20 Inch Quick Start (5 pages)

- CF500 Operator Manual (38 pages)

- PFH-15 Assembly Instructions (30 pages)

- 3500TM Parts Manual (106 pages)

- 1800TM Parts Manual (158 pages)

- YP2425A-2470 24 Row 70 cm Quick Start (5 pages)

- Simba Culti Press Operator Manual (38 pages)

- RU1999 Parts Manual (58 pages)

- 3N-30P Assembly Instructions (10 pages)

- 2510HDP Operator Manual (180 pages)

- YP1220 Parts Manual (136 pages)

- 3P500 Material Rate (68 pages)

- YP2425-3620 36 Row 20 Inch Quick Start (5 pages)

- 706NT Operator Manual (53 pages)

- 706NT Operator Manual (22 pages)