Section alignment – Great Plains 3N4010HDA Operator Manual User Manual

Page 62

58

3N-4010HDA

Great Plains Manufacturing, Inc.

196-444M

2013-09-24

Section Alignment

To check and adjust section alignment:

6.

Unfold drill, see “Unfolding” on page 26, and place a

block ahead of each wing gauge wheel. Pull drill for-

ward against blocks to rock frames back. Pull forward

until stop bolts are firmly against toolbars.

Refer to Figure 56

7.

Check for proper alignment by running a string line

across back of drill toward outer ends of wings. Mea-

sure to the back face of the tool bar supporting the

row units.

For proper alignment, outside ends of wings (dimen-

sion

) should be 0-to-

1

⁄

4

in (0-to-6.4mm) ahead of

inside ends (dimension

).

Refer to Figure 57

8.

To adjust section alignment, shorten or lengthen stop

bolts to change the contact point with the toolbars.

Adjust stop bolts

in or out until dimension

is 0 to

1

⁄

4

in greater than dimension

.

Lack of proper fold cylinder adjustment can cause diffi-

culties with gauge wheels by not allowing full rotation of

gauge wheel arm assemblies.

Note: If you have trouble getting a section aligned, it may

be necessary to adjust fold cylinders, see “Adjust-

ing Fold Cylinders” on page 55. Do not

over-adjust or you may cause fold latching prob-

lems.

Note: Section alignment, fold cylinder and tongue

spacer shim adjustments are closely interrelated

and may have to be adjusted in tandem. Adjust

fold cylinders to enable complete 90 degrees of

travel to latch wings and to unfold for section align-

ment. Then adjust tongue shims to remove as

much play as possible in transport without pre-

venting proper latch operation.

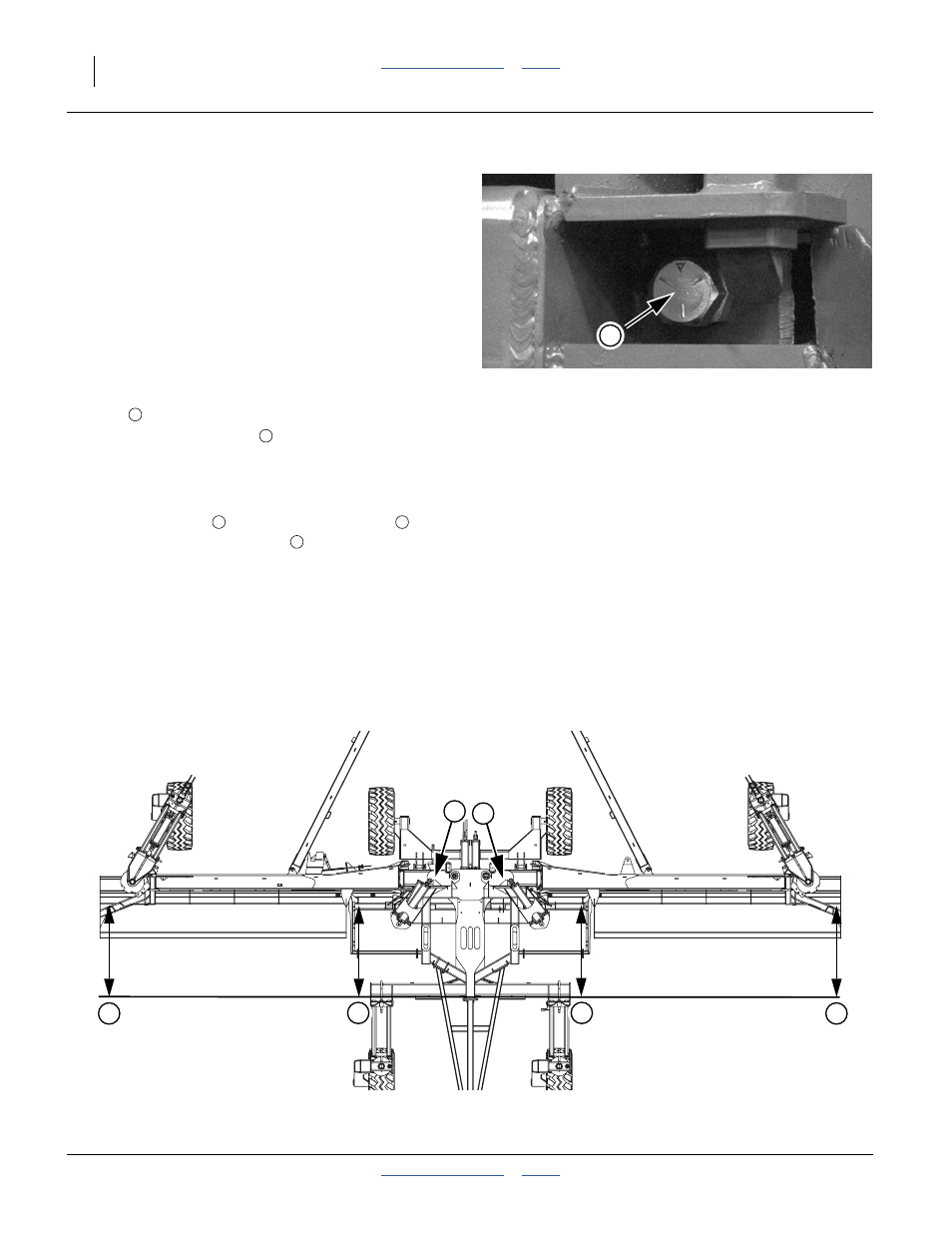

Figure 56

Stop Bolt

20317

7

Figure 57

Section Alignment

27119

7

7

8

9

8

9

9

8

7

9

8