Great Plains 3N4010HDA Operator Manual User Manual

Page 56

52

3N-4010HDA

Great Plains Manufacturing, Inc.

196-444M

2013-09-24

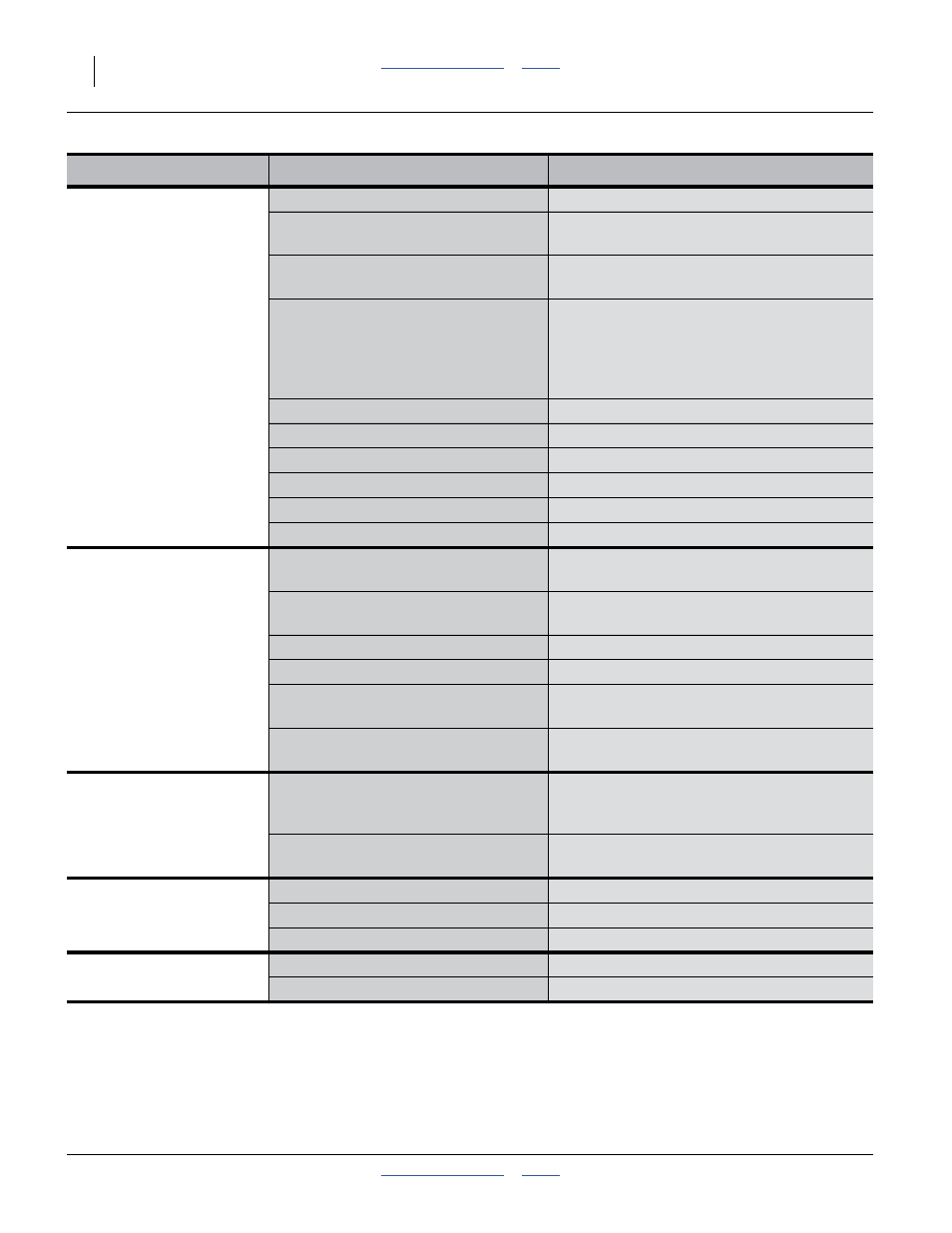

Press wheel or openers

plugging

Planting conditions too wet

Wait until drier weather.

Coulters not set deep enough to cut

residue

Check coulter adjustment.

Coulters set too deep, bring up excess

dirt and moisture

Check coulter adjustment.

Drill not set to run level from front to

rear, carrying enough weight on gauge

wheels to prevent “nosing over”, or set

too low on rear caster eyebolts allowing

it to run “nose high”

Check “Leveling Drill” on page 56.

Opener set too deep

Opener spring force too high

Backed up with drill in the ground

Clean out and check for damage.

Failed disk bearings

Replace disk bearings.

Disk blades worn

Adjust or replace disk blades, page 46.

Scraper worn or damaged

Replace scraper blade.

Marker Malfunction

Air or oil leaks in hose fittings or con-

nections

Check all hose fittings and connections for air

or oil leaks.

Market circuit not selected

Check Fold/Marker selector valve (if installed

on drill)

Low tractor hydraulic oil level

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners

Check all bolts and fasteners.

Needle valve plugged (single marker)

Open needle valve, cycle markers slowly and

reset needle valve, refer to page 62.

Needle valve(s) in sequence valve

plugged

Open needle valves, cycle markers slowly

and reset needle valves, refer to page 62.

Marker disk does not

mark

Marker folding linkage does not have

enough slack to allow marker disk to

drop into field depressions

Disk angle or orientation not optimal

Angle marker disk blade, or reverse blade to

pull or throw dirt.

Drill does not fold or

unfold fully

Air in lines

Bleed fold system.

Cylinder mounts misaligned

Check spacers, page 55.

Fluid run-out

Check tractor fluid level.

Drill hunts in transport

Worn skid blocks

Replace blocks or add shims

Locks not engaged

Check lock operation

Problem

Cause

Solution