Filter maintenance – Great Plains TSF1290 Operator Manual User Manual

Page 67

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

63

05/10/2012

500-641M

Filter Maintenance

There are two filters on the sprayer. One is a canister

type that filters the water entering the tank and the other

is a Whirlfilter® that filters the chemical solution being

sprayed.

These need to be cleaned seasonally, or sooner if flow

restriction is observed.

Clean-out the solution Whirlfilter®

Fill the sprayer tank with water and turn the pump on.

2.

With the pump running, slowly open the clean-out

valve and allow the grit to flow out into a bucket.

Clean out the solution Whirlfilter® only when the

sprayer tank is filled with water and no chemical has

been added.

3.

Close the clean-out valve and turn off the pump.

4.

Dispose of the grit and water in the same manner

described on the manufacturer’s label of the latest

chemical used in the sprayer.

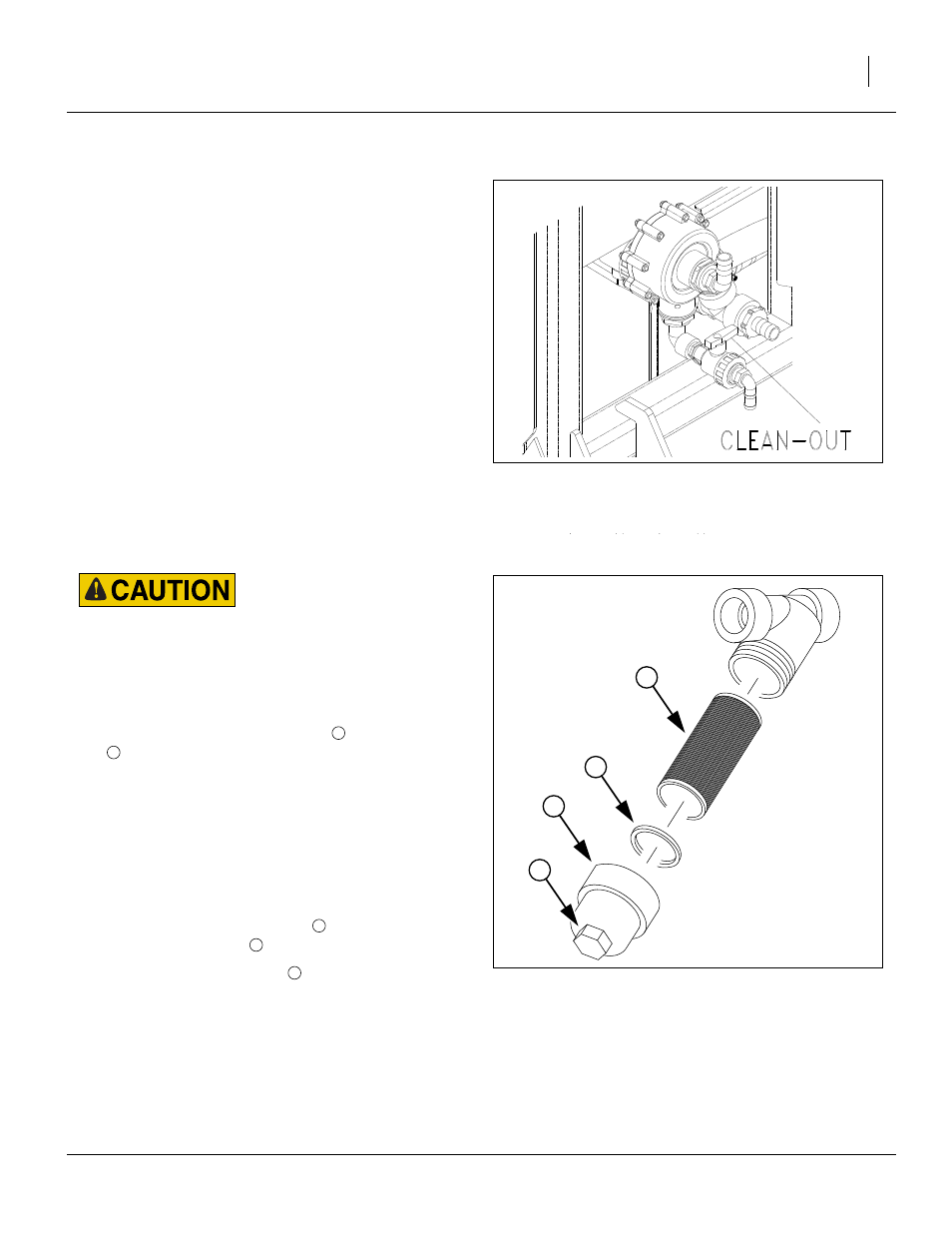

Clean Out Tank Fill Filter

Wear chemical gloves and protective clothing. Although used

for adding clean water, the chemical mix in the main tank can

back-wash into this assembly.

Start with an empty sprayer tank.

2.

Position a bucket under the plug

in the sump cap

of the filter. Remove the plug and allow the grit to

fall out.

3.

Screw the plug back in using pipe thread sealant to

seal the plug.

4.

Dispose of the grit and water in the same manner

described on the manufacturer’s label of the latest

chemical used in the sprayer.

If draining the filter does not improve flow:

5.

Unscrew the entire sump cap

. Remove it slowly

and save the gasket

.

6.

Remove the filter element

. Clean or replace it.

7.

Re-assemble the filter. No thread sealant is required

on the main cap threads.

Figure 54

Whirlfilter Clean-Out Valve

15787

Figure 55

Tank Inlet Filter

21808

2

4

1

3

2