Tank and boom flush – Great Plains TSF1290 Operator Manual User Manual

Page 57

Great Plains Manufacturing, Inc.

Operations

53

05/10/2012

500-641M

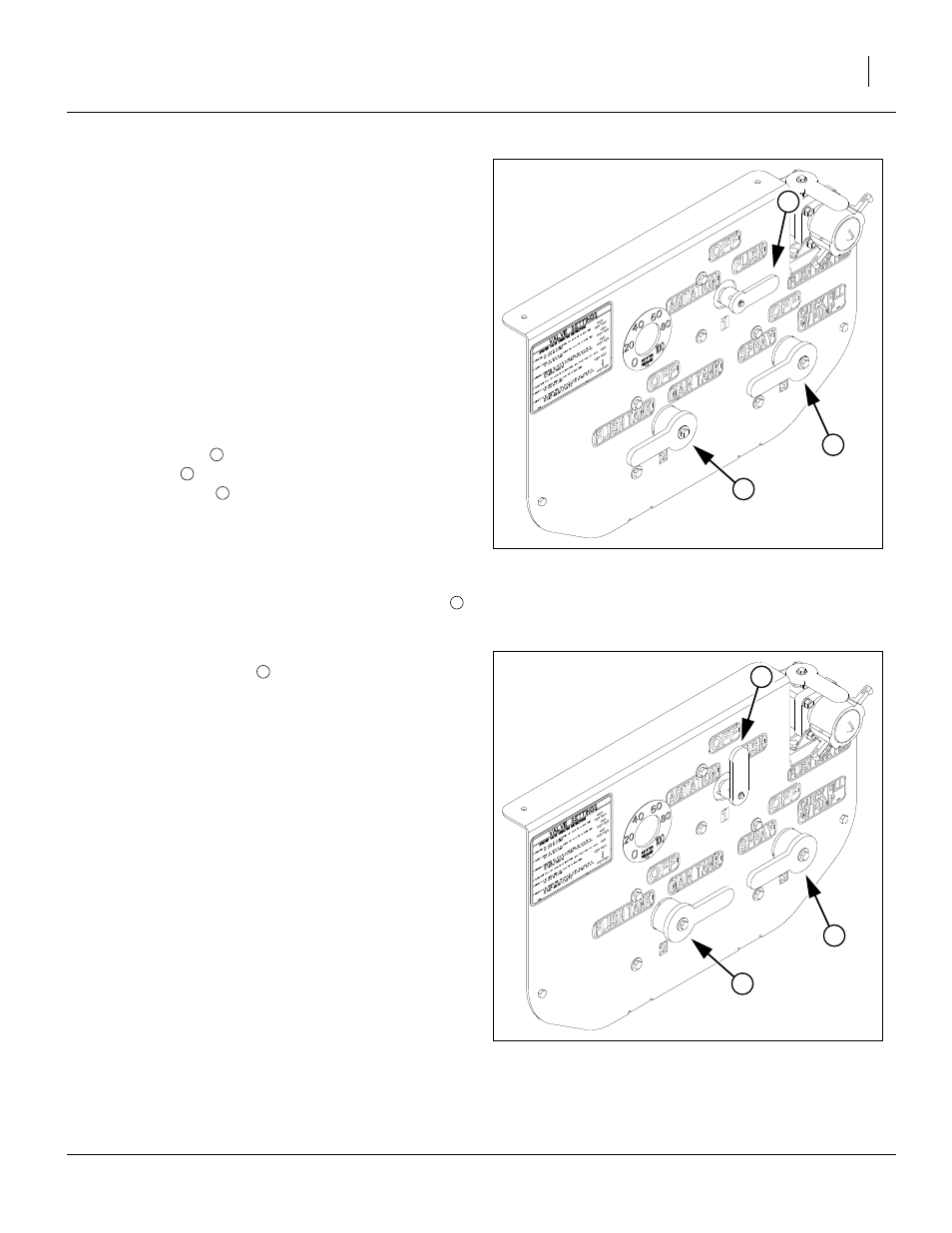

Tank and Boom Flush

The Tank Rinse and Flush features use the fresh water in

the 100 gallon flush tank to rinse out the main sprayer

tank and boom in the field.

Before operation, make sure the Flush tank is filled with

fresh, clean water.

1.

Completely empty the chemical in the main sprayer

tank by turning the agitation off the last pass and

spraying the main tank contents out in the field. To

avoid overdosing, use a higher ground speed or

lower application rate.

2.

Make sure all boom valves and pump are turned off.

Set the panel valves to:

agitation valve

to “FLUSH”,

tank valve

“FLUSH TANK”, and

operation valve

“SPRAY”.

4.

Operate the pump with the sprayer stationary, and

rinse the tank until

1

⁄

3

of the flush tank volume (33

gallons or 126 liters) is consumed and then stop the

pump.

5.

With the sprayer pump off, turn the agitation valve

from “FLUSH” to “OFF”.

Rotate the tank valve

from “FLUSH TANK” to

“MAIN TANK”.

7.

Operate the pump and spray out, in the field just fin-

ished, the full 33 gallon (126 liter) volume of liquid

(deposited into the main sprayer tank from the Flush

Tank).

8.

Repeat step 2 through step 7 twice more until the

flush tank is empty and the main sprayer tank and

boom has been rinsed completely three times.

9.

Reset the agitation pressure before filling the main

sprayer tank again.

Figure 46

Panel for Tank Rinse

22672

2

3

1

2

3

1

Figure 47

Panel for Boom Flush

22673

2

3

1

2