Operating pump unloading materials, Operating pump, Unloading materials – Great Plains TSF1290 Operator Manual User Manual

Page 56

52

TSF1080, TSF1090, TSF1280 & TSF1290

Great Plains Manufacturing, Inc.

500-641M

05/10/2012

Operating Pump

Rotating drive line contact can cause death. KEEP AWAY! Do

not operate without guards attached and drive line securely

attached at both ends.

To operate the PTO pumps, engage the PTO shaft slowly

at the tractor’s idle throttle position. Slowly accelerate to

the desired PTO RPM. On a 540 RPM pump, the RPM of

the PTO would be the speed at which the dead head

pressure reaches 80 PSI or 540 RPM. On a 1000 RPM

pump, the RPM of the PTO would be the speed at which

the dead head pressure reaches 80 PSI or 1000 RPM.

Never operate the PTO pump without the tractor PTO shield in

place, and the pump torque bar firmly chained in place.

1.

To operate the hydraulic pump, first make sure that

the hydraulic hoses are routed correctly so that the

pump turns in the correct direction. See “Hitching

with Hydraulic Pump” on page 20.

2.

To run the pump, push the hydraulic lever in the

“down” position.

3.

When stopping the pump, push the hydraulic lever in

the “float” position.

Note: Do not move the hydraulic lever to the neutral posi-

tion while the hydraulic pump is running. To do so

may cause damage to the hydraulic pump.

Unloading Materials

Sprayed chemicals are normally diluted in water for

application, and cannot be recaptured and stored for re-

use.

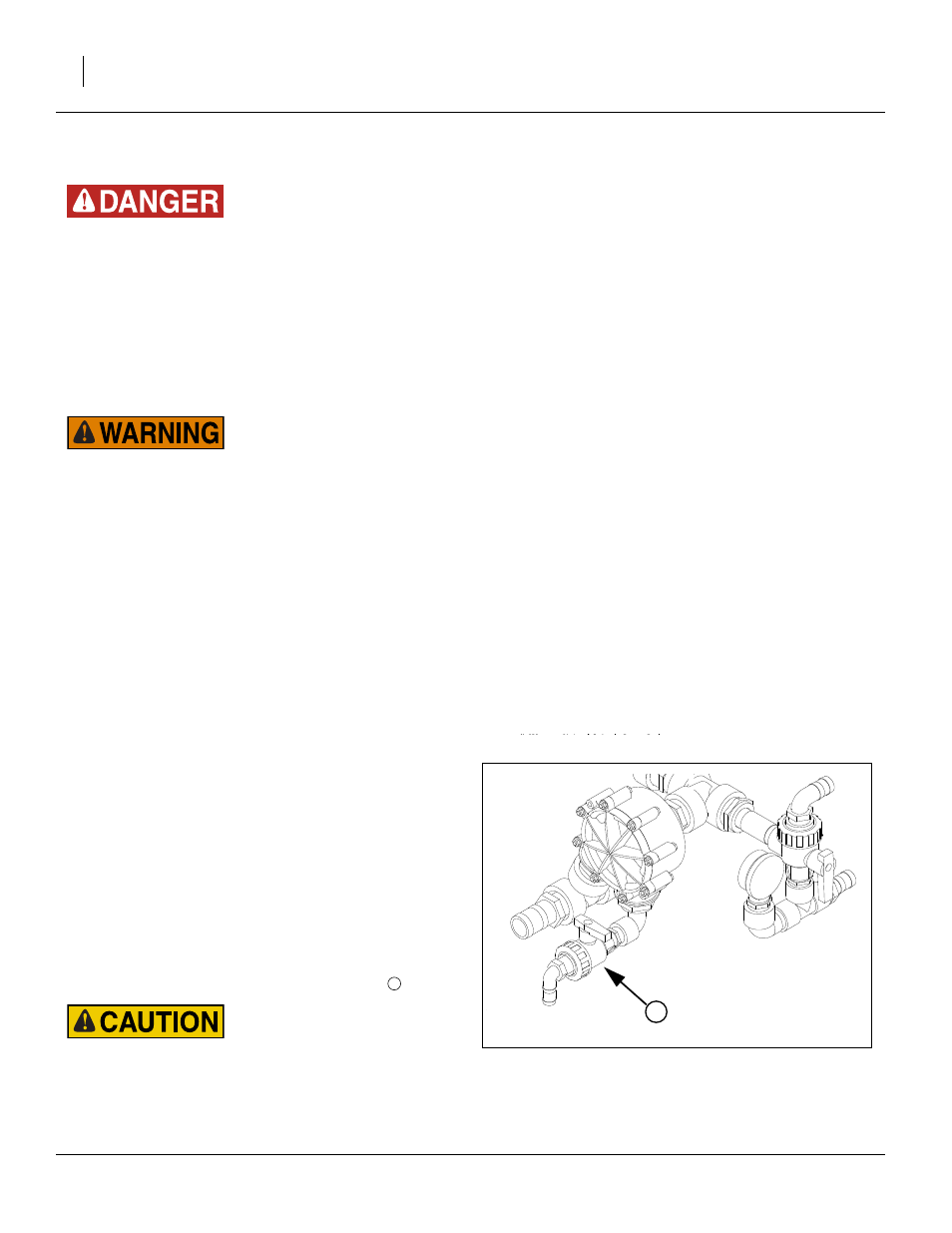

Refer to Figure 45

If a small amount of material remains in the main tank at

completion of spraying, one method of disposing of it is

to apply it to the same fields. To avoid an overdose of

material, reduce the rate or further dilute the tank con-

tents with water (but don’t use the Flush tank water for

this - reserve it for final tank flush and clean-out).

If material must be drained from the tank, rather than

applied via boom, drain at the Whirlfilter sump

.

Do not attempt to drain the main tank by removing the main

sump cap. Potentially hazardous materials will spray in ran-

dom directions as the clamp is being removed.

Figure 45

Whirlfilter Sump

20403

1

1