Axle wheel spacing adjustment – Great Plains TSF1290 Operator Manual User Manual

Page 62

58

TSF1080, TSF1090, TSF1280 & TSF1290

Great Plains Manufacturing, Inc.

500-641M

05/10/2012

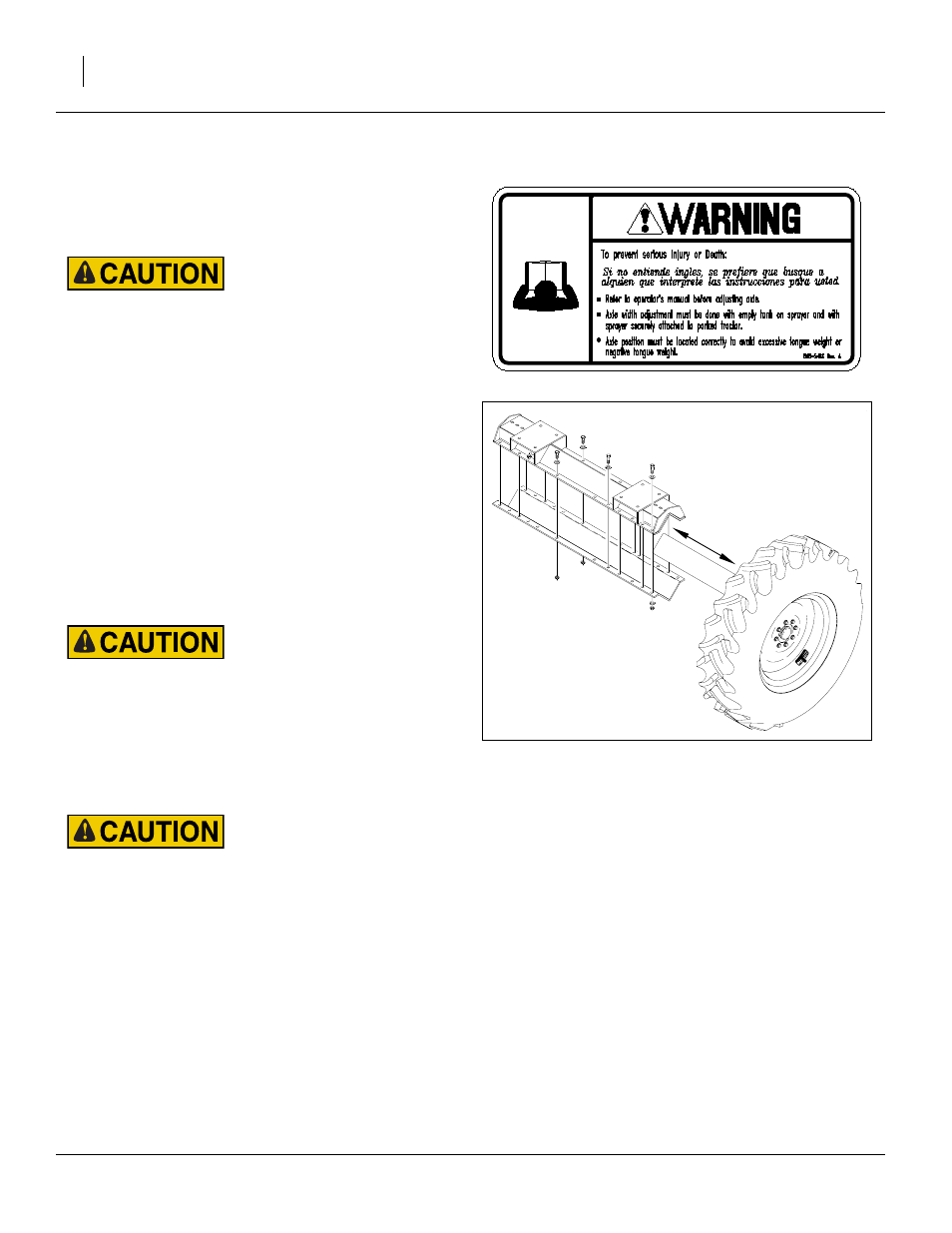

Axle Wheel Spacing Adjustment

Refer to Figure 52

Axle extension can be adjusted for differing row spac-

ings.

Do not change the fore/aft position of the axle mount, Moving

it forward may result in negative tongue weight even when

folded. Moving it aft increases positive tongue weight and

risks tire contact with boom.

1.

Hitch the sprayer on level ground.

2.

Measure the current wheel spacing (span) between

tread center-lines.

Note: Also measure the distance from the outer end of

each axle to the mount. Keep these equal, or the

sprayer will pull skewed.

3.

Compute the difference between the current and

desired spans. Divide it by two. This is the amount to

extend or retract each axle.

4.

Use a hoist or jacks at the left rear corner of the

mainframe to raise the sprayer until the tire on that

side (only) is slightly elevated off the ground.

Leave the other tire firmly on the ground to provide resistance

to lateral frame movement when adjusting an axle.

5.

Loosen the bolts joining the upper and lower axle

mounts, starting with the bolts nearest the wheel

being adjusted. Loosen only enough bolts to allow

movement of the axle to be adjusted.

6.

Slide the axle in or out to the new setting.

Do not adjust the wheel spacing wider than:

120in (305cm) on North American models, or

290cm (114in) on export models

at tire tread center lines. To do so may cause a falling axle

hazard while the sprayer is in service.

7.

Secure the four bolts nearest the tire.

8.

Lower the adjusted side.

9.

Elevate the right corner, and repeat step 5 through

step 8.

10. Tighten all the bolts to “Torque Values” on page 80.

Figure 52

Wheel Axle Adjustment

13855