Great Plains 3PYPA Operator Manual User Manual

Page 96

92

3PYPA

Great Plains Manufacturing, Inc.

401-647M

03/20/2012

Null4.aac:

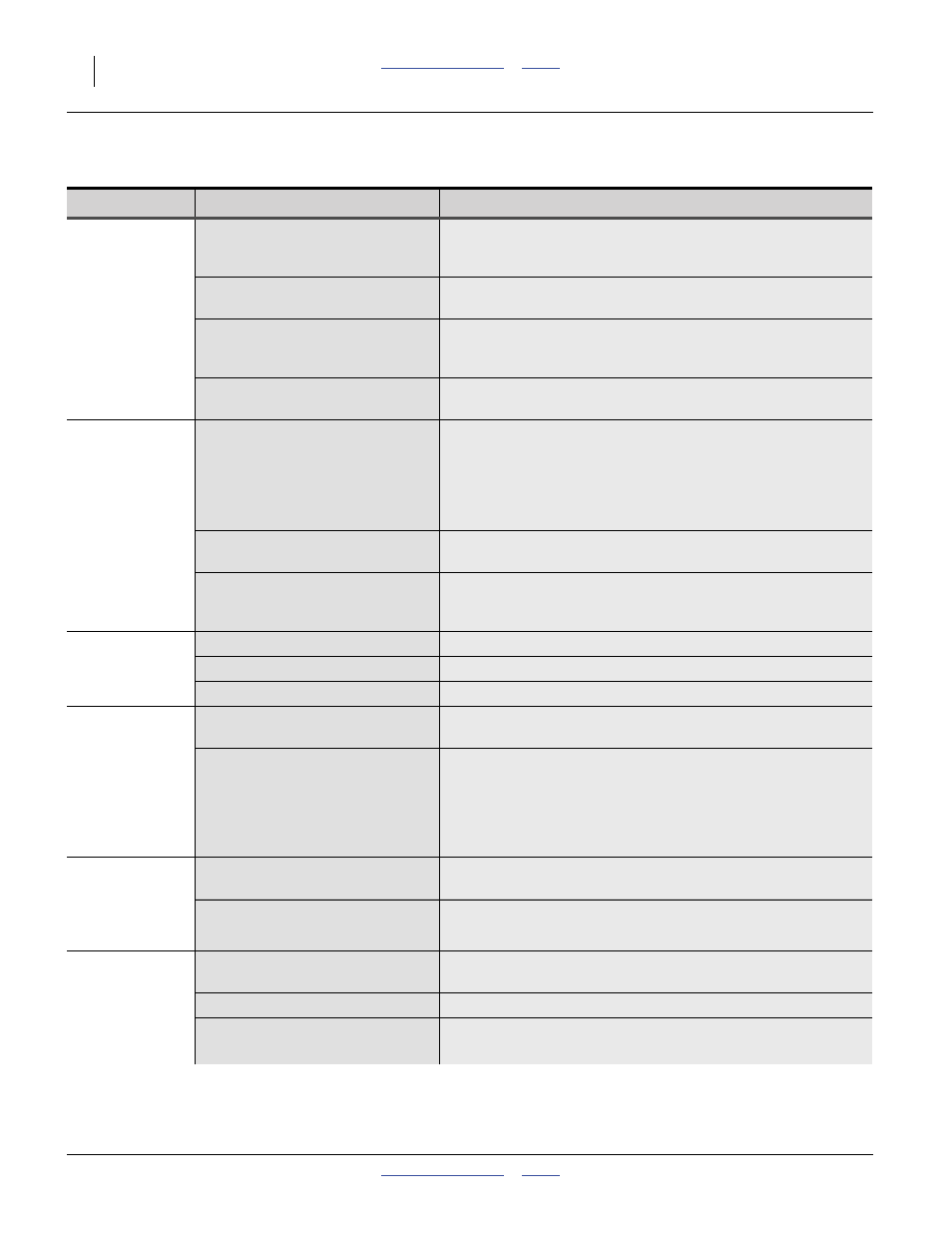

Population Related

Problem

Cause

Solution

Overall

Population

Alarms

False alarms or actual rate errors

due to monitor setup with incor-

rect [active] row count or spacing

When troubleshooting population issues, always first rule out

seed monitor setup. Review planter configuration and monitor

setup.

Incorrect cell count

Replace seed disks with correct disks, or reset rate for current

disks (if within range).

Improper gap on speed sensor.

Check speed sensor on planter for

1

⁄

16

in to

1

⁄

8

in (1.6-3.2mm)

gap from wheel. Improper gap can cause erratic speed signal

causing monitor to falsely report improper planting rate.

Incorrect speed sensor constant

Perform speed calibration per DICKEY-john

®

monitor man-

ual.

Mismatch

Between

Reported and

Furrow

Population

Small seeds (example milo) are

not reliably sensed in the seed

tube

Run with rain covers in place to minimize ambient light intru-

sion. Use the population adjustment factor in the Dickey John

monitor system to compensate for missed seeds. For exam-

ple, change the DICKEY-john

®

Population Adjustment values

from 100% to 130% or 140% as needed. Remember to set

this back to 100% for large seeds.

Seed tube sensor is not counting

all seeds

Clean the seed tube of graphite and dust buildup with long

narrow seed tube brush. Replace sensors that malfunction.

Seeds / revolution value in the

DICKEY-john

®

setup does not

match the disk cell count.

Correct the value in a setup screen or install the correct cell

count disc.

Excessive

Seed

Cracking

Incorrect seed pocket size

Use correct disk for seed.

Damaged, old or dried-out seed

Use new seed.

Unclean seed

Use clean seed.

Skips and

Bare Spots

After Turns

Fan was turned off at turns

Leave fan running. Meter Pressurization must be maintained

during turns, or seed will fall out of disk pockets.

Insufficient hydraulic flow to keep

fan running at speed required to

maintain meter pressurization

Check tractor capability against requirements (page 138).

If sufficient:

• Fold markers before engaging lift.

• Use a less aggressive lift rate.

• Monitor fan rpm during end-of-pass operations.

Unable to

adjust air

pressure low

enough.

Lower limit reached in

DICKEY-john

®

software.

At User Level 2, reduce the controlled air lower limit in the

software.

Fan speed too high, vane rotated

to maximum.

Reduce the fan speed.

Seed too

shallow or

scattered on

ground from a

single row

Bottom of seed tube damaged.

Replace seed tube. Avoid setting planter straight down. Use

forward motion when lowering.

Row not penetrating in tire tracks. Increase down force on parallel arm springs.

Opener depth too shallow.

Change side depth wheel setting.