Great Plains 3PYPA Operator Manual User Manual

Page 56

52

3PYPA

Great Plains Manufacturing, Inc.

401-647M

03/20/2012

Null4:

Null4:

Null4:

Null4:

Null4:

Null4:

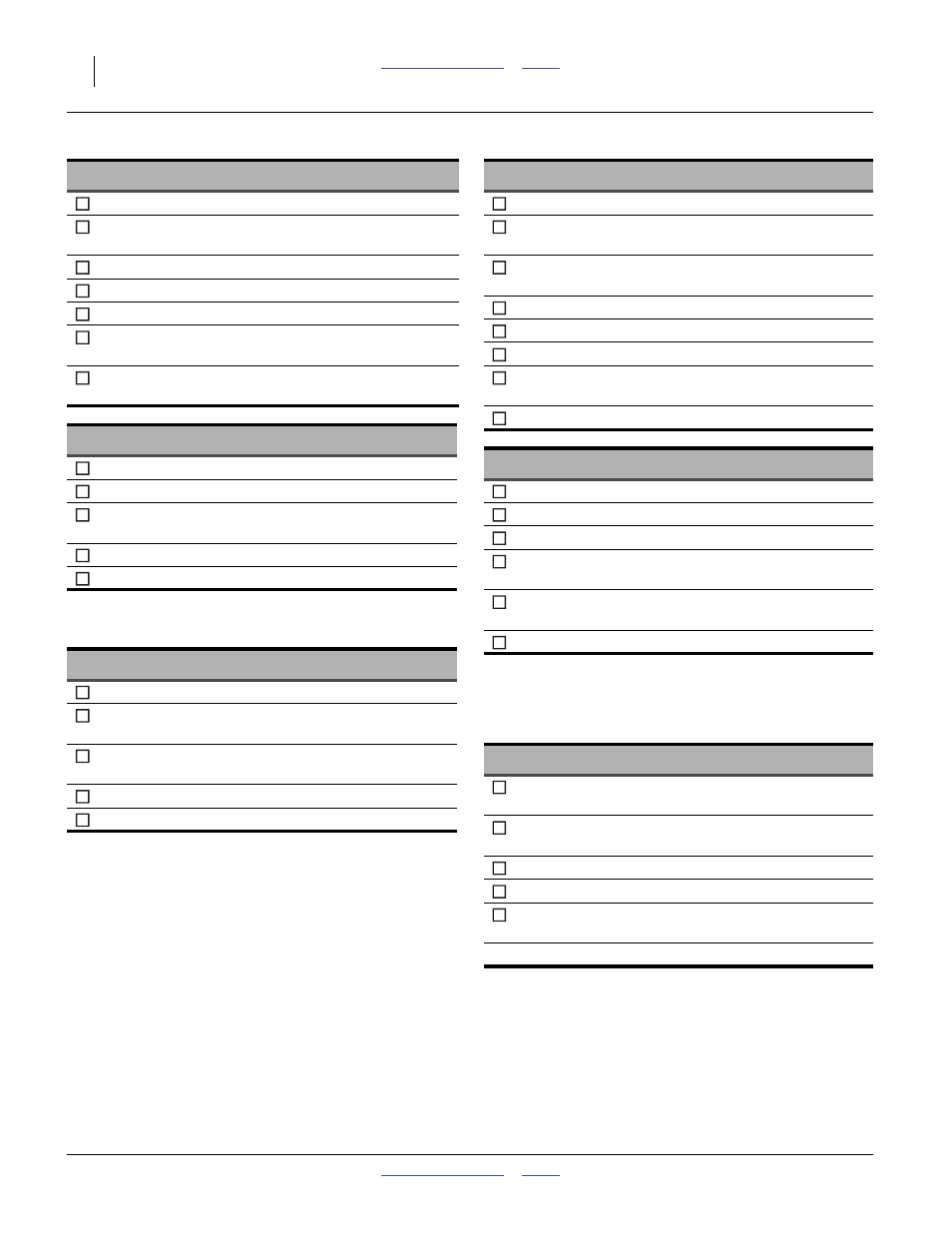

Air System Checklist

Page

Manifold to seed box or hopper seal

-

Add 2 cups of seed lubricant to air box,

prior to first use, and prior to loading seed

Seed loaded. Lids closed and latched.

37

Y-tubes turned on for active rows

80

No air leaks (except from seed box)

-

Hose routings - no sags, no pinches (check

wing-folded & field positions)

-

Hoses fully connected to meters and

locked

-

Planter Hydraulic Drive Checklist

Page

Check chain lubrication and slack

Input initial values for desired population

a

a. Refer to monitor manual and Seed Rate manual.

Calibrate radar speed sensor pulses with

planter lowered.

b

b. Refer to seed monitor manual.

Lubricate slider joints on drive shafts

Check clutch operation

Planter Ground Drive Checklist

Page

Check chain lubrication and slack

Set/check Range, Transmission and Upper

Drive sprockets against rate chart

a

a. Refer to Seed Rate manual.

Calibrate radar speed sensor pulses with

planter lowered.

b

b. Refer to seed monitor manual.

Lubricate slider joints on drive shafts

Check clutch operation

Row Units Checklist

Page

Preset depth handles alike.

Preset down force springs alike, except in

tracks.

Set all unit-mounted coulters to

1

⁄

4

in shal-

lower than opener blades.

71

Check coulter alignment to row

72

Check closing wheel alignment

Set press wheels alike, except in tracks.

Check action and contact of side depth

wheels

Check wheel scraper gaps (if installed)

Treatments (Options) Checklist

Page

Check tractor-mounted components

a

a. Check supplier manual for tanks and pump. Check

fertilizer section of monitor manual.

Check for correct orifice plates

b

b. Check Seed Rate manual, and manual for fertilizer

pump system.

Check relief valve setting

66

Fill system with 100 gallons of water, and

check for leaks

-

Check all row unit lines connected, free of

kinks, and discharge tube/nozzles clear

-

Inlet and hose valves open

-

Meters Checklist

Page

Corn?

Check timing of meters for twin-row

Check chain tension. Re-connect any

loose idler tensioning springs.

-

Correct disks for seed

a

a. Refer to Seed Rate manual.

Start fan. Operate at field rpms.

Rotate meter drive shafts one turn disks

with seed.

b. With optional hydraulic drive, speed this process by

performing a “FILL METER” operation.

a.

Refer to Seed Rate manual.