Great Plains 3PYPA Operator Manual User Manual

Page 95

Great Plains Manufacturing, Inc.

Troubleshooting

91

03/20/2012

401-647M

Null4.aac:

Metadata: End of “Population Too High“

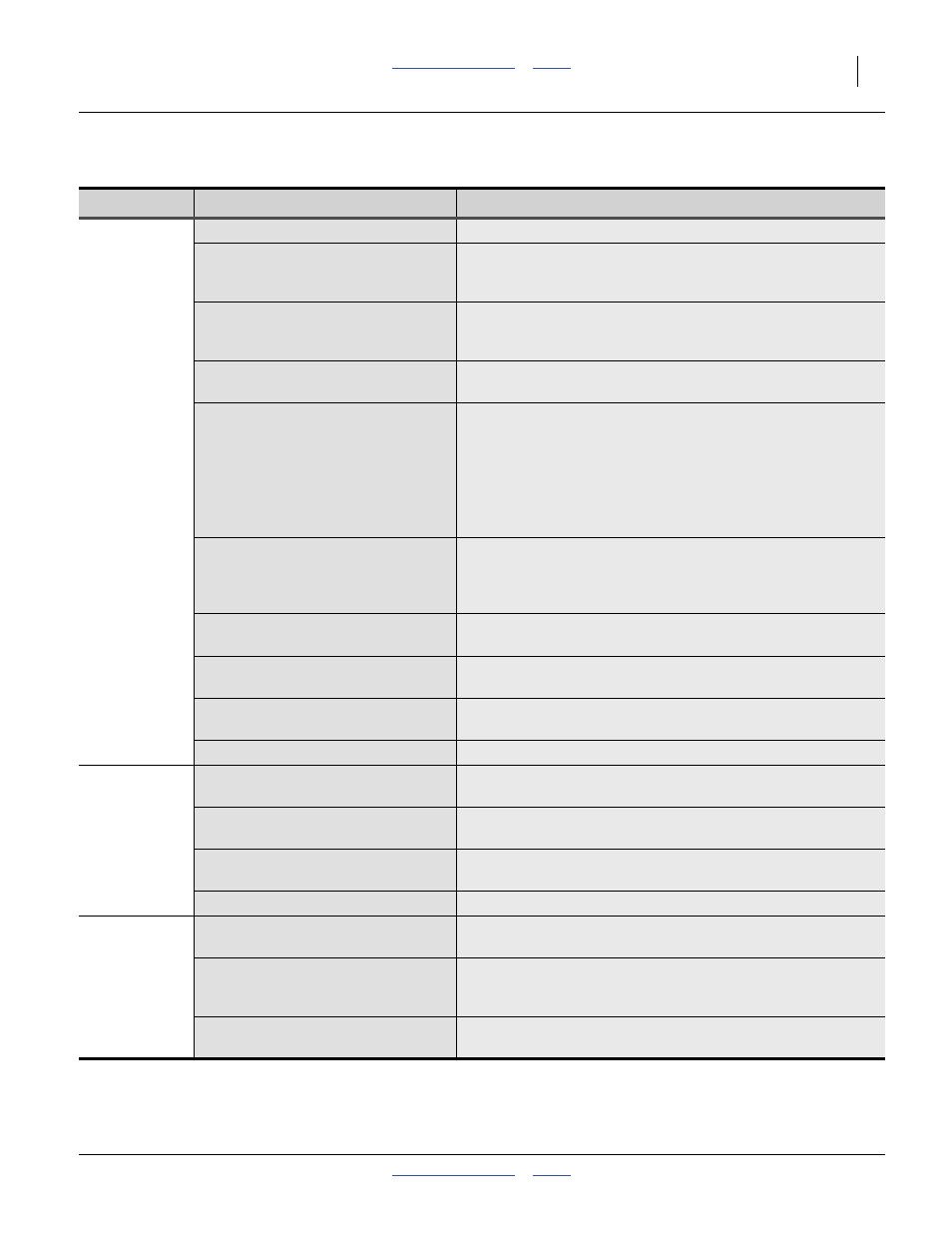

Population Too High

Problem

Cause

Solution

Overall High

Population

Incorrect seed rate

Check seed rate charts

Two seeds per pocket on the disk

(doubles), due to excess meter pres-

surization

Methodically decrease the controlled air to the meter. See

“Fan and Adjustment” on page 62.

Two seeds per pocket on the disk

(doubles), due to pockets too large

for the seed

Select a disk with smaller pockets.

Air meter pressure too high due to

pressure sensor not zeroed properly.

Re-zero the air pressure with the fan off. Make sure the dis-

played pressure reads 0.00.

Air pressure too high, false informa-

tion driving the DICKEY-john

®

soft-

ware.

Compare the air pressure reported on the monitor console to

the mechanical gage. If they do not match:

• Inspect the

1

⁄

4

in sample lines from the row units up to the

sensor chamber for leaks.

• Make sure all non-planting rows have blank disks.

• Re-zero the air pressure with the fan off.

False alarms or actual seed rate

errors due to monitor setup with

incorrect row count, spacing or

active rows

When troubleshooting population issues, always first rule out

seed monitor setup. Review planter configuration and moni-

tor setup.

Incorrect cell count

Replace seed disks with correct disks, or reset rate for cur-

rent disks (if within range).

Incorrect speed sensor constant

Perform speed calibration per DICKEY-john

®

monitor man-

ual.

Doubles due to incorrect disk for

crop or seed size

Use recommended disk for crop and seed size.

Sticky seeds: excess seed treatment Increase seed lubricant.

Overall High

Population,

cont.

Speed sensor angle.

With planter lowered, check radar speed sensor angle per

DICKEY-john

®

recommendations.

Incorrect speed sensor constant

Perform speed calibration per DICKEY-john

®

monitor man-

ual.

Overlapping passes

Check marker extension (page 164).

For GPS, check planter size programmed.

Actual field size is different

Population may be correct, and calculations are not.

High

Population,

Single Row

Excess meter pressurization causing

doubles

Check shutter.

Worn seed-drop brush and/or strip

brushes allowing excess seed to

pass

Replace worn brushes.

Incorrect seed disk with higher cell

count.

Install correct disk.