Seed-lok® seed firmer lock-up, Press wheel adjustment, Press wheel down pressure – Great Plains 3PYPA Operator Manual User Manual

Page 87

Great Plains Manufacturing, Inc.

Adjustments

83

03/20/2012

401-647M

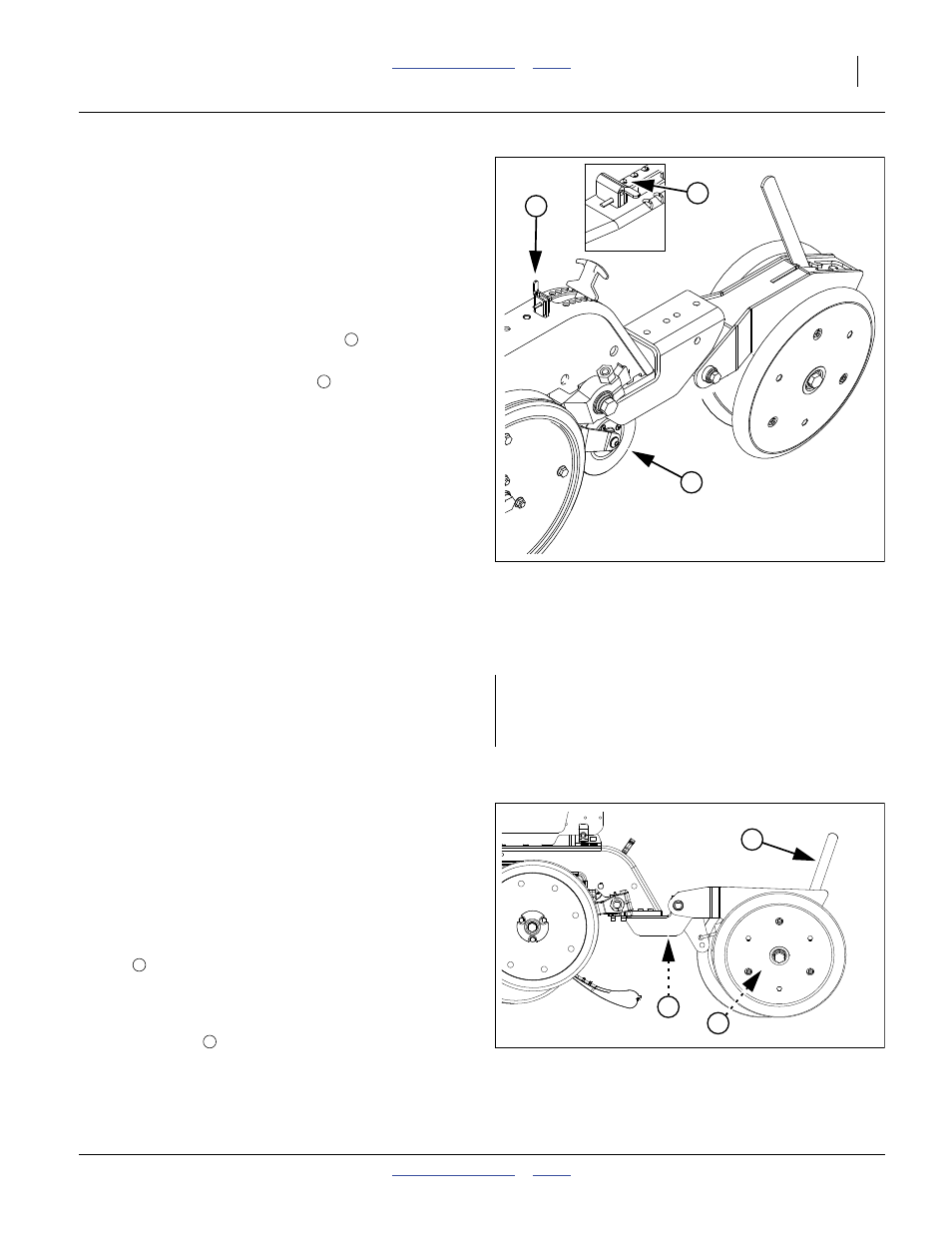

Seed-Lok® Seed Firmer Lock-Up

Optional Seed-Lok® firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and

do not require adjusting. In some wet and sticky condi-

tions the wheels may accumulate soil. To avoid problems

associated with this, you can lock-up the firmers.

Refer to Figure 113

To lock up Seed-Lok® wheels:

1.

Raise planter. Insert lift assist cylinder locks.

2.

Rotate Seed-Lok® lock-up handle

90 degrees

down on top of row unit body.

3.

Push up on Seed-Lok® wheel

until wheel arm

latches up.

Press Wheel Adjustment

The press wheels close the furrow which gently presses

the soil over the seed to ensure good seed-to-soil con-

tact for even emergence.

To provide consistent seed firming, the press wheels are

free to move downward from their normal operating posi-

tion. This system maintains closing/pressing action even

if the row unit arm is lifted when the disks encounter

obstructions.

There are three adjustments available on the press

wheel assembly and a fourth option on press wheel

assemblies with cast wheels:

Refer to Figure 114

1.

Down pressure (shown at maximum)

2.

Wheel stagger (shown staggered)

3.

Centering (see Figure 116 on page 84)

4.

Cast Wheel Plow Angle (see Figure 117 on page 85)

Press Wheel Down Pressure

Handle

sets down pressure, which may need adjust-

ment for different soil types and field conditions.

• Relax the handle forward (in the direction of travel) for

decreased down pressure.

• Pull the handle

back for increased down pressure.

Note: Higher press wheel down pressures reduce the

down force on the main row unit shank compo-

nents, such as the openers. High press wheel set-

tings may require an increase in overall row unit

down force. See page 68.

Null4:

Figure 113

Seed-Lok® Lock-Up

22909

2

3

1

2

3

Higher press wheel down pressures reduce the down

force on the main row unit shank components, such as

the openers. High press wheel settings may require an

increase in overall row unit down force. See page 68.

Null4:

Figure 114

Press Wheel Adjustments

25118

1

3

2

1

1