Air pressure gauge, Check for air leaks, Setting the springs – Great Plains 3PYPA Operator Manual User Manual

Page 177

Great Plains Manufacturing, Inc.

Appendix R - Row Pro

173

03/20/2012

401-647M

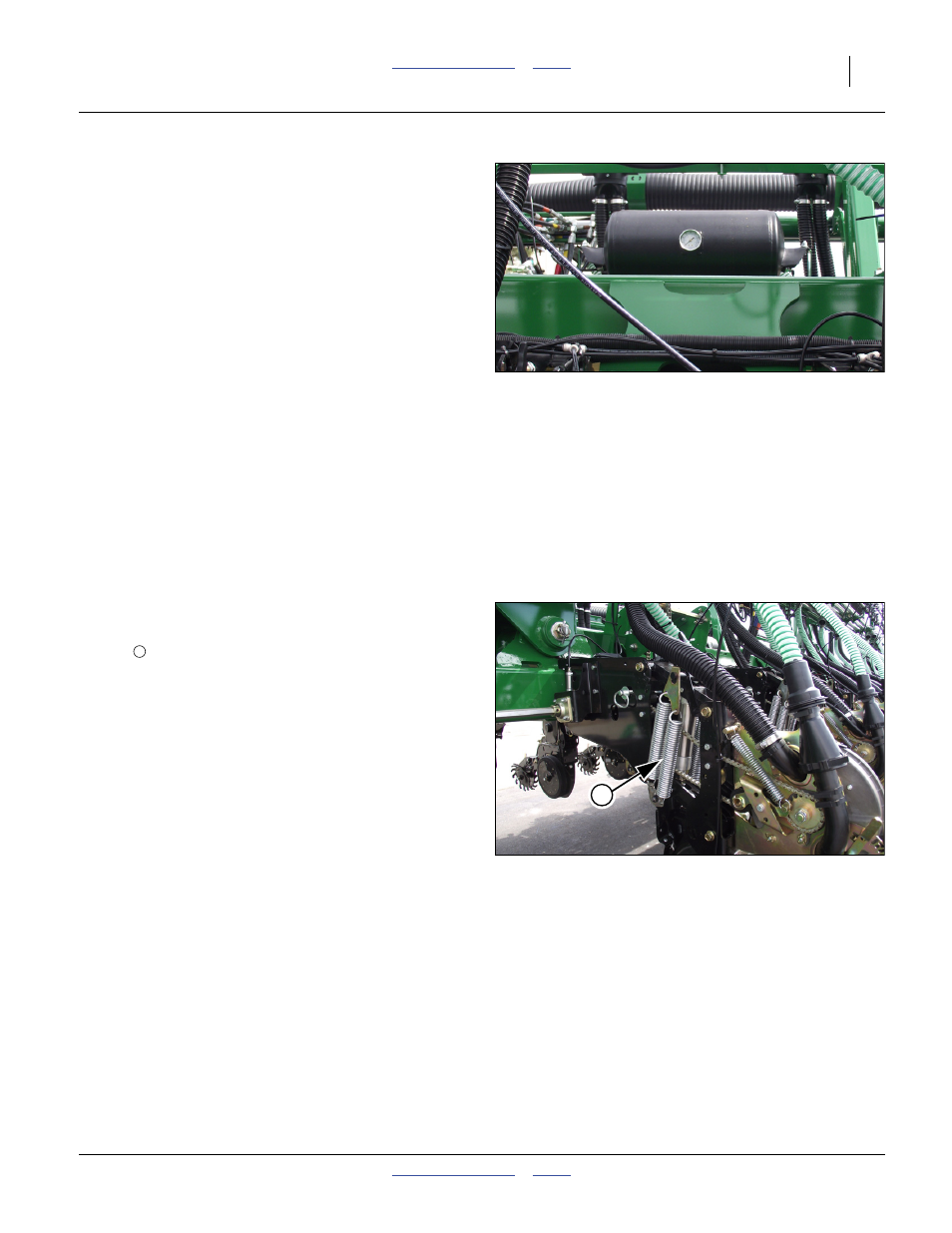

Air Pressure Gauge

Refer to Figure 178

Row-Pro™ is designed to run at 150 psi. When the psi

drops to 135 the compressor engages and builds back

up to 150 psi. Duty cycle varies based on air usage.

Check for Air Leaks

Before going to the field check for air leaks.

1.

Turn the compressor on and let it pressure up the

primary system until it automatically shuts off. If the

system loses pressure then check for leaks.

2.

The cylinders can be pressurized to check for leaks

by setting IntelliAg

®

down pressure Control Mode to

“manual” and activating the “decrease” button. It can

be set to add air to individual sections or all sections

at once.

Setting the Springs

Refer to Figure 111

When going to the field, using the adjuster cam, set the

springs

to the highest tension that is needed to keep

the down pressure and the system at the target rate.

The actual target rate is going to be different depending

on the field conditions, soil type and other factors. The

only way to gauge where you want the setting is to oper-

ate the system for a short time then go behind the planter

and check the furrow.

Note: Adjustment to the spring pressure may need to be

made if the depth is reset or the closing wheel down

pressure is adjusted.

IntelliAg

®

tracks the pressure and sends warnings:

• High Alarm: too much pressure, move spring pressure

down.

• Low Alarm: too little pressure, kick spring pressure up.

Null4:

Null4:

Figure 178

Air Pressure Gauge

32098

Null4:

Figure 179

Setting the Springs

32085

1

1