Operation, Maintenance – Tweco 2460 Heavy Duty CC CV Control Wire Feeder User Manual

Page 34

NOTE: An Allen wrench is supplied for

tightening the Feed Roll Screws. It is

“stored” in a nylon retainer, located on

the rear end of the Feedhead Cover. See

Figure 6.

6. To install the upper two Feed Rolls, follow the

procedure below:

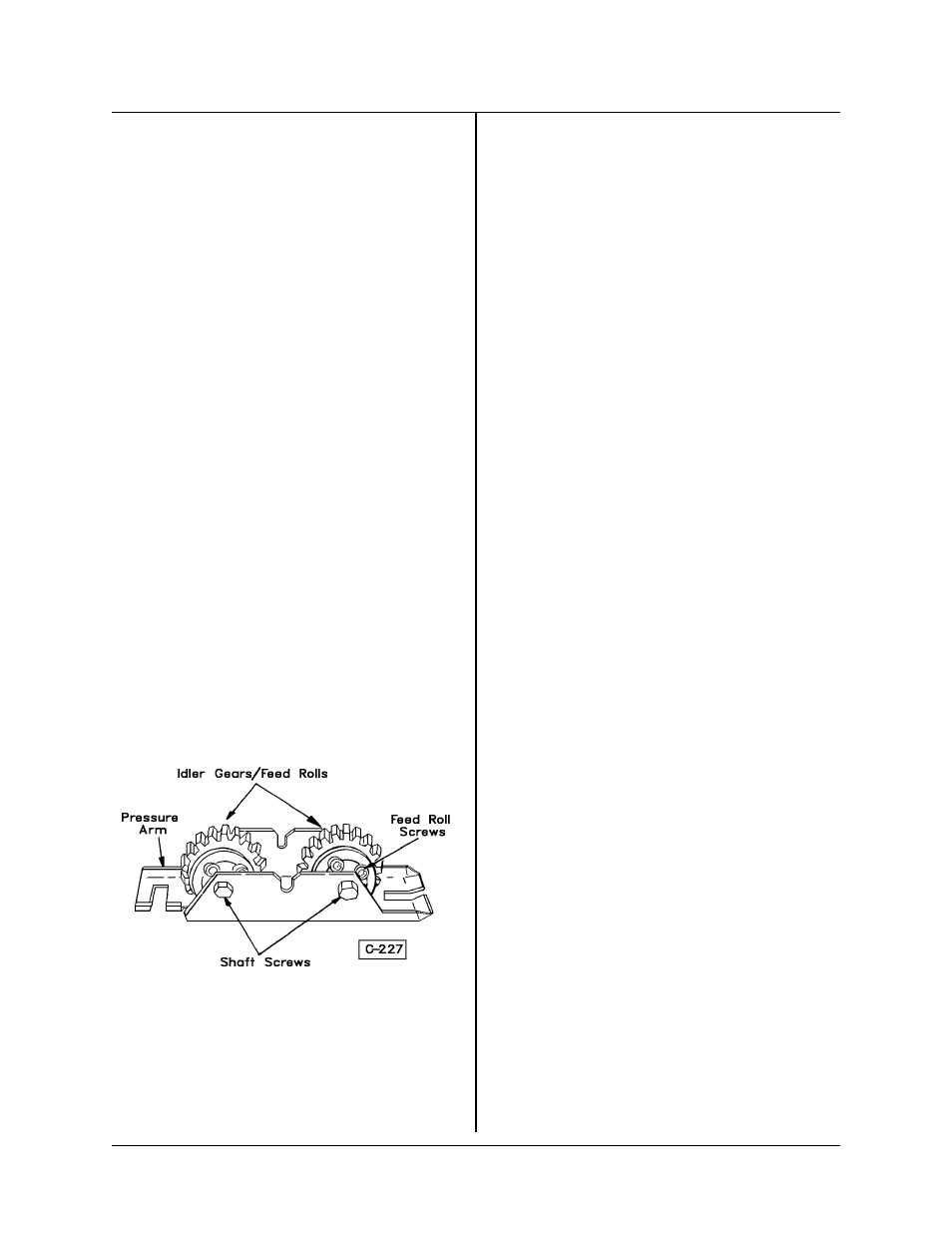

a. Remove shaft screws which secure the

Idler Gear/Shaft in place in the pressure arm.

See Figure 5.

b. Install the Feed Rolls onto the Idler Gears,

and secure in place with the Feed Roll

Screws. See Figure 4.

NOTE: When installing a Style 4 Feed

Roll, which is made up of two pieces, be

sure to place the narrow piece on the

gear first. This makes the groove line up

with the Guides.

c. Reinstall the Idler Gears/Feed Rolls into

the Pressure Arm. Fasten in place with the

Shaft Screws. See Figure 5.

d. Reassemble Pressure Arm onto the Feed-

head Assembly by dropping it into place (see

Figure 2) and adjusting the Pressure Arm

Knobs for proper tension. Adjust Center

Guide so that clearance between Guide and

the first Feed Roll is approximately 1/32 inch

(0.8 mm). Tighten Center Guide Retaining

Screw.

Input Guides

1. Loosen the Input Guide Retaining Screw and

pull the Input Guide Spring (Item 1, Figure 1) out of

the hex nylon Input Guide.

2. Insert the steel or nylatron Input Guide into the

hex nylon Input Guide.

NOTE: The hex nylon Input Guide is a

holding device for the Input Guide Spring

and the Input Guide which is supplied in

the Feed Roll and Guides Kit (375980-*).

*The dash number denotes which Feed

Rolls and Guides are furnished.

3. Reinstall the Input Guide Spring, pushing it

against the Input Guide, and tighten the Retaining

Screw.

Output Guide — The Output Guide may be in-

stalled with the Gun Sleeve and the Gas Inlet (all

models) in place.

1. Loosen the Output Guide Retaining Screw (see

Figure 2), and turn it out far enough to allow the

Guide to slide in or out.

2. Insert the Guide into the Feedhead with long-

nosed pliers or a piece of welding wire. Push the

Guide up to the Feed Rolls until it “bottoms out”

inside the Feedhead and tighten the Retaining

Screw.

3. Proceed to install the Gun and Cable Assembly

as detailed above under Installing Gun and Cable

Assembly.

Operation

The operation of this feedhead is a function of the

wire feeder assembly of which it becomes a part.

See the Wire Feeder Manual for the 2000 Series for

details which affect this operation.

Maintenance

Cleaning — Periodically blow off the feedhead

assembly with clean, dry, compressed air of not

more than 25 psi (172 kPa) pressure. Use care to

not strike component parts of the feedhead with the

air hose nozzle.

Cleaning Feed Rolls and Gears — Using a small

wire brush, clean the grooves on the feed rolls and

gear teeth frequently. To clean the wire groove,

loosen the Pressure Arm Knob and raise the Pres-

sure Arm. Remove the wire from the feed rolls.

Clean the gear teeth and check the screws which

hold the feed rolls on the gears.

Feedhead Maintenance — The only point of main-

tenance in the feedhead assembly is the motor

brushes. To inspect and/or change the brushes, the

feedhead assembly must be removed from the Con-

Figure 5

TIP-219

FEEDHEAD ASSEMBLY NO. 376799A-1, -2, -3, -4

Page 4

December 1, 1997 Revised