Tabulated data, Control box assembly, Wire reel support assembly – Tweco 2460 Heavy Duty CC CV Control Wire Feeder User Manual

Page 14: Baseplate, Options

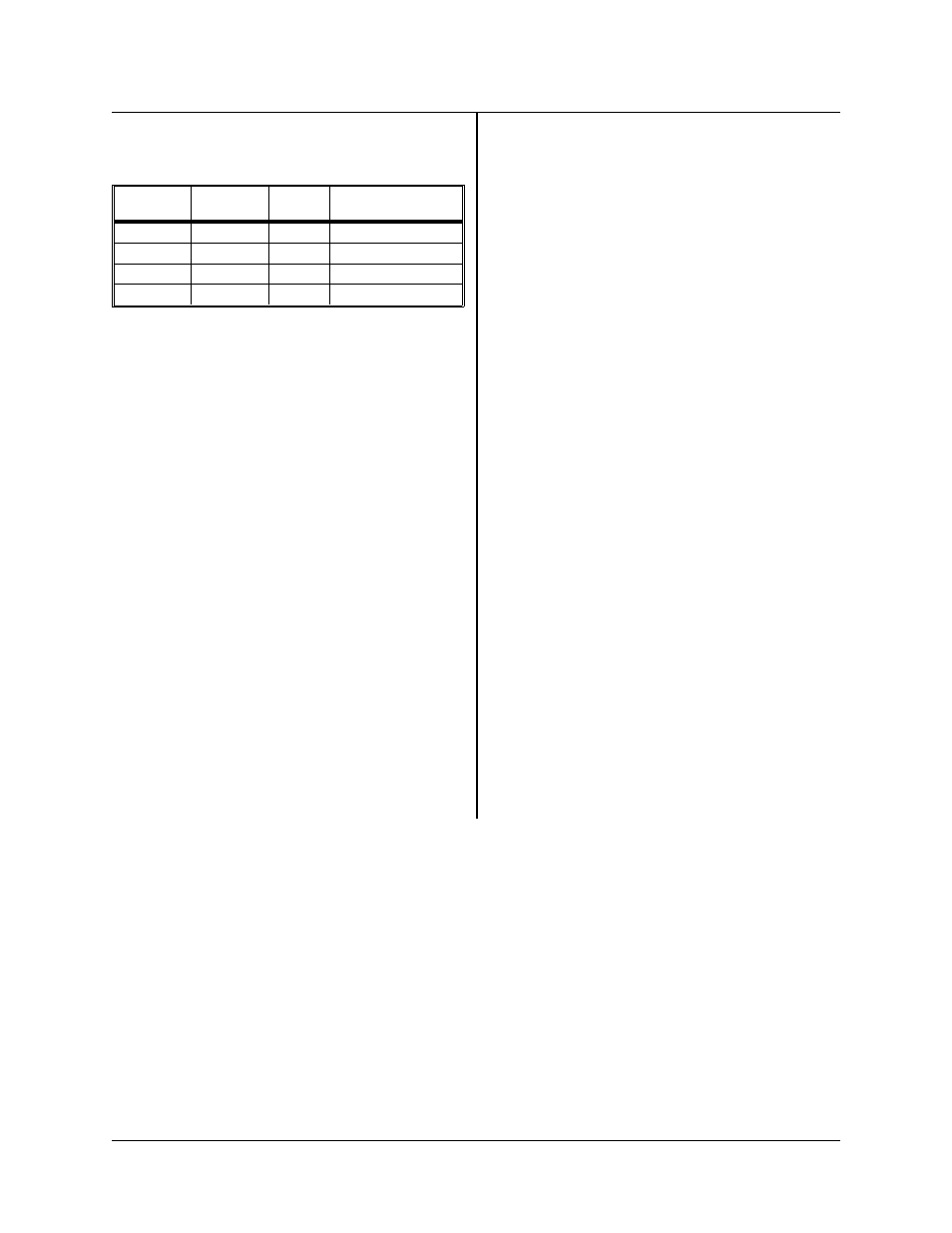

depending upon which wire feed rate is desired. See

Table 3-1 for correlation of numbers.

The assemblies consist of Feed Rolls (which are

made up of a Gear and Feed Roll) for various wire

types and/or sizes, Wire Input Guide, Output Guide,

Feedhead Mounting Plate, and Pressure Arm as-

sembly. The drive motor is 24 volts DC. See TIP-218

for details on the Feedhead Assembly. See Feed

Roll Kit drawing 375980 for selecting part numbers

for the Feed Rolls, Wire Guides, Contact Tubes, etc.

Tabulated Data

Gearmotor

Permanent magnet

24 V DC, 1/8.8 HP

5A

±

.5 amps

Speed:

123 RPM

±

12 RPM

57 RPM

±

5.7 RPM

(optional @ no

load)

Voltages

Motor

24 V DC

Gun Circuit

11 V DC or 24 V AC

(option)

Speed Range of Wire

20.4:1 drive gear ratio — 40 to 600 IPM

(inches/minute)

43.9:1 drive gear ratio — 20 to 300 IPM

(inches/minute) (optional)

Wire Data

Spool weight

60 pounds

(27.2 kg) max.

Sizes

1/8 inch (3.17 mm)

and smaller

Control Box Assembly

The Control Box contains control and connection

for the operation and component hook-up with the

particular welding system it is being used with. See

TIP-218 and MPL-224 included in this manual.

Wire Reel Support Assembly

The support bolts in place at the rear of the base-

plate. See I-169 included in this manual for details

on the installation and operation of the wire support

assembly.

Baseplate

See TIP-127 for details on the baseplate used for

this wire feeder when assembled to make the sub-

ject model configuration.

Options

The options available with this unit are as follows:

SPEC.

MODEL

FEED

ROLLS

WIRE FEED

RATE

6877A-1

2460

4

40-600 IPM

6877B-1

2460

4

40-600 IPM

6877A-2

2460

4

20-300 IPM

6877B-2

2460

4

20-300 IPM

Table 3-1

430429-249

DESCRIPTION OF EQUIPMENT

3-2

May 22, 1997 Revised