Installation – Tweco 2460 Heavy Duty CC CV Control Wire Feeder User Manual

Page 31

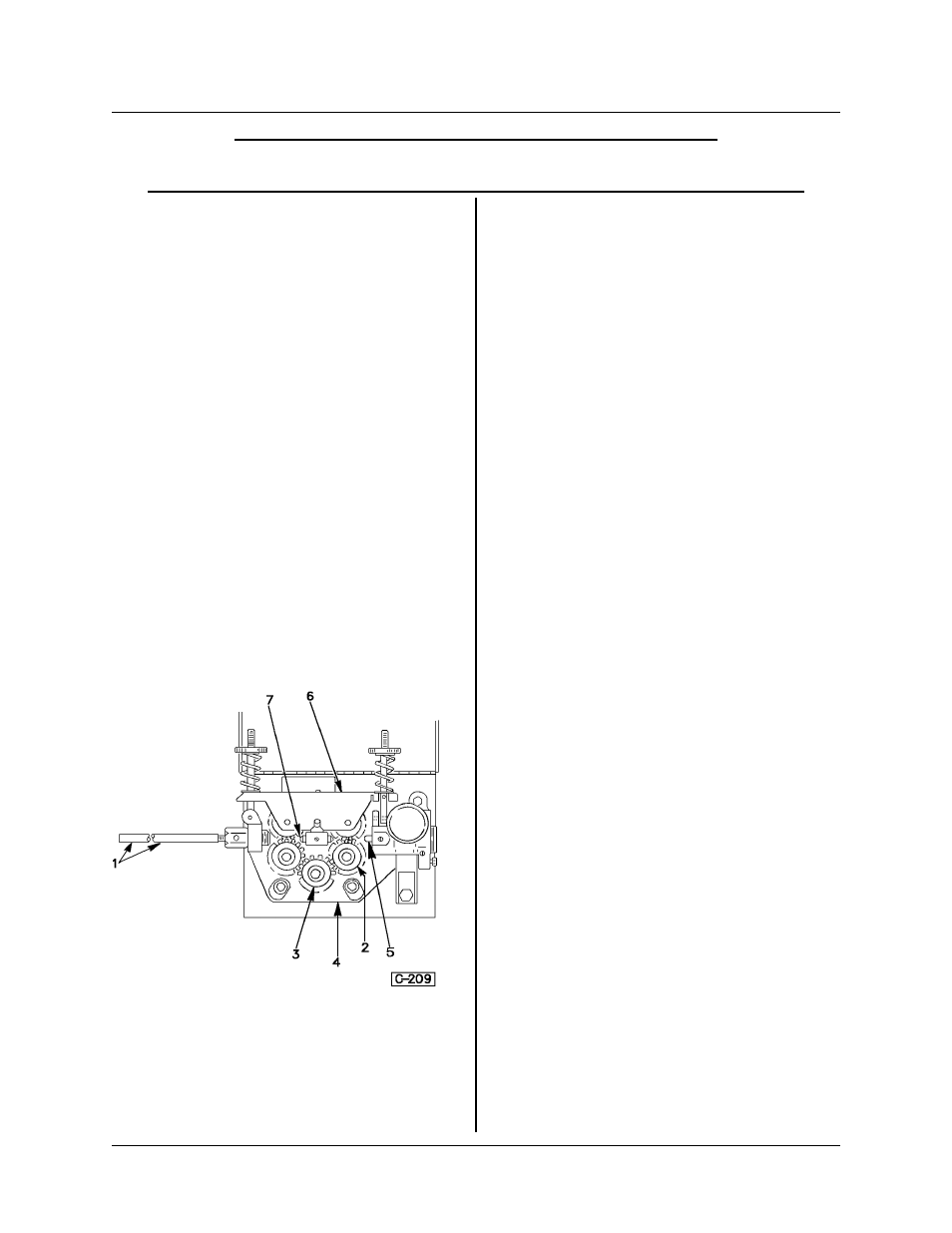

FEEDHEAD ASSEMBLY NO. 376799A-1, -2, -3, -4

DESCRIPTION, INSTALLATION, OPERATION AND MAINTENANCE

Description

The four-roll feedhead assembly consists of four

idler gear/feed rolls (item 2, Figure 1) for various

types and sizes of wire. See Feed Roll Kit (375980),

wire input guide (item 1), center guide (item 7),

output guide (item 5), feedhead plate (item 4) and

pressure arm assembly (item 6). The drive motor is

115 volt DC, controlled by solid-state or variac

speed control. See the data on the particular model

which is found in the manual of which this TIP is a

part.

Wire sizes from 0.030-inch (0.76 mm) diameter to

1/8 inch (3.18 mm) may be fed with selection of

proper feed rolls. See Feed Roll Kit (Drawing

375980-X, included in this manual) for feed roll

configuration and proper feed rolls for given sizes

and types of wire.

The Solenoid (Gas Control) Valve (optional) is

located on the back side of the Feedhead Plate. A

fitting for gas supply extends through the back panel

of the Control Box.

Installation

The feedhead assembly becomes a part of the

modular assembly which includes a control box

assembly, and a wire support assembly which may

be mounted on a common baseplate, or remotely

mounted, as on a boom unit.

Location — For best operating characteristics and

longest unit life, take care in selecting an installation

site. Avoid locations exposed to dust, high ambient

temperature, or corrosive fumes.

Connections — The electrical connections for the

wire feeder are made both at the feedhead and

control box. The feedhead connection is made from

the power supply terminal to the feedhead as with

standard feeders. However, the feeder motor and

controls use the feedhead potential to supply oper-

ating power for the feeder. Be sure the cable con-

nection to the feedhead is tight. A loose cable will

cause the feeder to malfunction.

Installation of Welding Wire Spool — See I-169 for

details.

Adjustment of Spool Tension — Adjust the tension

on the Wire Spool so that the wire will feed freely

into the feedhead (feed rolls), but will not “coast”

when wire feeding stops. Tighten or loosen the Hub

Tension Screw accordingly.

Threading Wire Into Feedhead — Refer to Figure

2.

CAUTION: Use care when handling the

spooled wire as it tends to unravel when

loosened from the spool. Grasp the end

of the wire firmly; do not let it get away!

Make sure the end of the wire is free of

burrs, and that it is straight.

1. Loosen the Pressure Arm Knobs, and raise the

Pressure Arm UP as shown in Figure 2.

2. Place the end of the wire into the Input Guide,

feeding it through the guide and over the feed roll

grooves.

3. Pass the wire into the Output Guide and on into

the Gun Cable. See Owner’s Manual for the Gun

and Cable Assembly.

4. Make sure that the wire is directly over the

grooves in the feed rolls and replace the Pressure

Arm. Lock it in place with the Pressure Arm Knobs.

Figure 1

1. Input Guide

2. Idler Gear/Feed Roll

3. Drive Gear

4. Feedhead Plate

5. Output Guide

6. Pressure Arm

Assembly

7. Center Guide

TIP-219

FEEDHEAD ASSEMBLY NO. 376799A-1, -2, -3, -4

December 1, 1997 Revised

Page 1