06 system operation, 07 optional power supply settings – Tweco CE PAK Master 150XL Without Latch Circuit User Manual

Page 39

Manual 0-2696

4-7

OPERATION

4.06 System Operation

NOTE

Frequently review the safety precautions at the front

of this manual.

This section contains operating information which is specific

to the power supply. Detailed operating information for torches

can be found in the appropriate Torch

Instruction Manual.

WARNINGS

Disconnect primary power at the source before

assembling or disassembling power supply, torch

parts, or torch and leads assemblies, or adding cool-

ant.

It is not enough to simply move the ON/OFF

switch on the unit to OFF position when cutting

operations have been completed. Always open the

power supply disconnect switch five minutes after

the last cut is made.

A. Operational Suggestions

The suggestions below should be followed in all cutting

and gouging operations:

1. Wait five minutes before setting the ON/OFF switch

to OFF after operation. This allows the cooling fan to

run to dissipate operating heat from the power sup-

ply.

2. For maximum parts life, do not operate the pilot arc

any longer than necessary.

3. Use care in handling torch leads and protect them from

damage.

4. In continuous cutting applications using CO2, it is of-

ten necessary to manifold four to six cylinders together

to maintain adequate flow at operating pressures.

B. Fold Back Feature

Should the torch tip contact the workpiece or molten

slag, the output current will immediately drop to 35

amps to minimize potential tip damage.

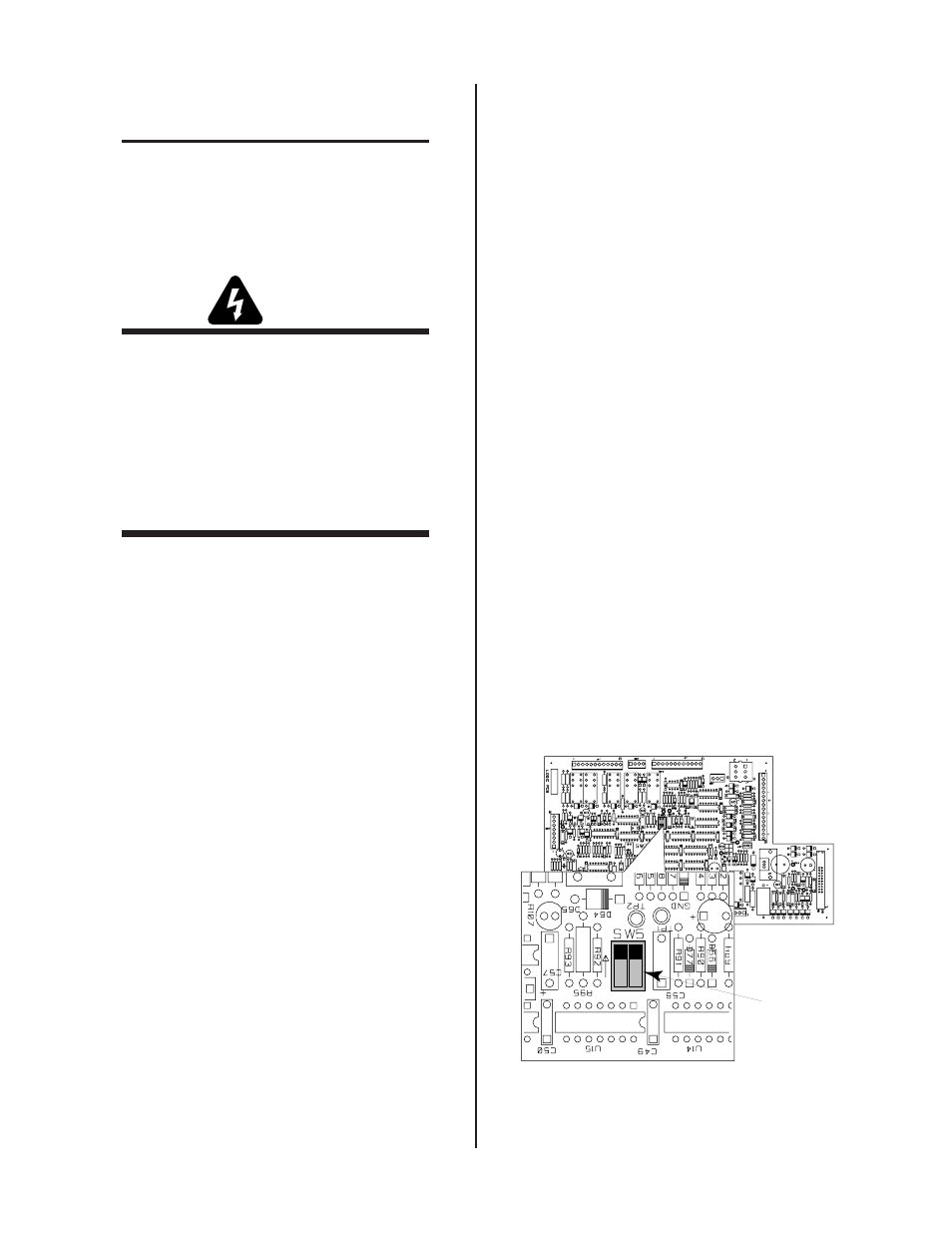

4.07 Optional Power Supply

Settings

The following functions can be used to tailor a system for

special application requirements or unique user prefer-

ences. These functions are controlled by DIP switches

located on the Logic Control PC board in the power sup-

ply.

Remove the left side panel and locate the Logic Control PC

Board near to top center of the unit. Set the function as

required.

A. High/Low Speed Auto-Restart Function

(SW5)

The Plasma Power Supply is always in the Auto-Restart

mode. This means that at the end of the cut, if the START

signal is still on, the pilot will restart automatically.

An immediate pilot restart, when cutting over holes or

expanded metal at relatively slow speeds, may cause the

arc to transfer back to the piece just cut. This happens

because the torch has not had time to be moved away

from the cut piece and results in extra starts and unnec-

essary parts wear.

The High/Low Speed Auto-Restart switch, SW5, has two

settings as follows:

• Low Speed - adds a one-tenth second delay to

the pilot restart to prevent arc back conditions.

• High Speed - no delay required as it may delay

starting on the next edge.

A-02258

Logic PC Board

SW5

1 2

Figure 4-8 High/Low Speed Auto-Restart Switch

SW5 Location