06 cut quality – Tweco PakMaster 100XL Plus User Manual

Page 27

Manual 0-2784

21

SECTION 4: OPERATION

B. Check primary power source as follows:

1. Check the power source for proper input voltage. Make

sure the input power source meets the power require-

ments for the unit per Section 2.03-A, Specifications/

Design Features.

2. Connect the input power cable (or close the main dis-

connect switch) to supply power to the system.

C. Gas Selection

Select desired gas (air or nitrogen). Make sure gas source

meets pressure and flow requirements (refer to Section

3.08, Gas Connections). Check connection and turn gas

supply on.

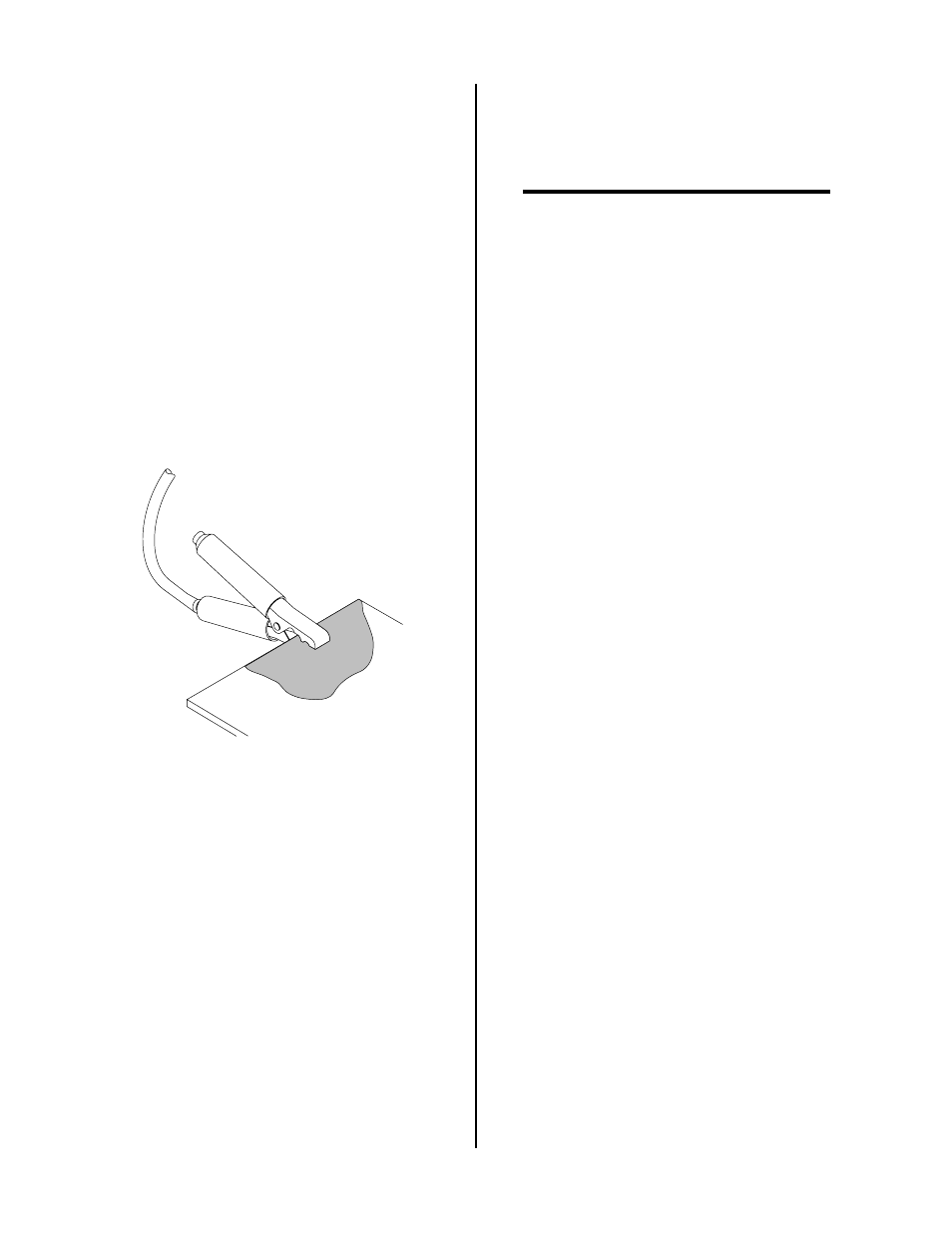

D. Work Cable Connection

Check for a solid and clean work cable connection to the

workpiece. The area must be free from paint and rust.

Make a solid work cable

connection to the work-

piece or cutting table

A-00925

Figure 4-8 Work Cable Connection To Workpiece

E. Torch Connection

Check that the torch is properly connected.

F. Power Supply On

Move the ON/OFF switch to ON position.

G. Select Output Current

Select the desired current output level for the operation.

• 15 to 80 amps for standoff cutting and gouging

• 15 to 35 amps for drag cutting

H. Set Operating Pressure

Move the RUN/SET/LATCH switch to SET position. Ad-

just the gas pressure to 70 psi (4.8 bar).

I. RUN/SET/LATCH Switch

Set the RUN/SET/LATCH switch to RUN position.

The system is now ready for operation.

NOTE

For general cutting, use the RUN position which

provides normal touch operation where the torch

switch must be held throughout the main arc trans-

fer.

For specific applications, use the LATCH position

where the torch switch can be released after the main

arc transfer. The torch remains activated until the

main arc breaks from the workpiece.

4.06 Cut Quality

Cut quality requirements differ depending on applica-

tion. For instance, nitride build-up and bevel angle may

be major factors when the surface will be welded after

cutting. Dross-free cutting is important when finish cut

quality is desired to avoid a secondary cleaning opera-

tion.

The following cut quality characteristics are illustrated

in Figure 4-9 below:

Cut Surface

The condition (smooth or rough) of the face of the cut.

Bevel Angle

The angle between the surface of the cut edge and a plane

perpendicular to the surface of the plate. A perfectly per-

pendicular cut would result in a 0° bevel angle.

Top-Edge Rounding

Rounding on the top edge of a cut due to wearing from

the initial contact of the plasma arc on the workpiece.

Dross Build-up and Top Spatter

Dross is molten material which is not blown out of the

cut area and re-solidifies on the plate. Top spatter is dross

which accumulates on the top surface of the workpiece.

Excessive dross may require secondary clean-up opera-

tions after cutting.

Kerf Width

The width of material removed during the cut.

Nitride Build-up

Nitride deposits which may remain on the surface of the

cut when nitrogen is present in the plasma gas stream.

Nitride buildups may create difficulties if the material is

welded after the cutting process.