07 connecting torch leads – Tweco PakMaster 100XL Plus User Manual

Page 20

SECTION 3: INSTALLATION PROCEDURES

14

Manual 0-2784

CAUTION

Pressure should be set at 100 psi (6.9 bar) at the

high pressure gas cylinder regulator.

a. Refer to the manufacturer’s specifications for in-

stallation and maintenance procedures for high

pressure gas regulators.

b. Examine the cylinder valves to be sure they are

clean and free of oil, grease or any foreign mate-

rial. Momentarily open each cylinder valve to blow

out any dust which may be present.

c. The cylinder must be equipped with an adjustable

high-pressure regulator capable of outlet pressures

up to 100 psi (6.9 bar) maximum and flows of up

to 300 scfh (141.5 lpm).

2. Slide the gas supply hose over the barb fitting installed

in Step 2.

3. Secure the gas supply hose inplace with the adjustable

hose clamp.

NOTE

Supply hose must be at least #4 hose (1/4 in or 6

mm I.D.).

3.07 Connecting Torch Leads

WARNING

Disconnect primary power at the source before as-

sembling or disassembling the power supply, torch

parts, or torch and leads assemblies.

The Torch Leads must be properly installed to the Power

Supply for proper operation. Make all torch connections

to the Torch Bulkhead Panel per the following:

NOTE

Equipment ordered as a system will have the Torch

factory connected to the Power Supply.

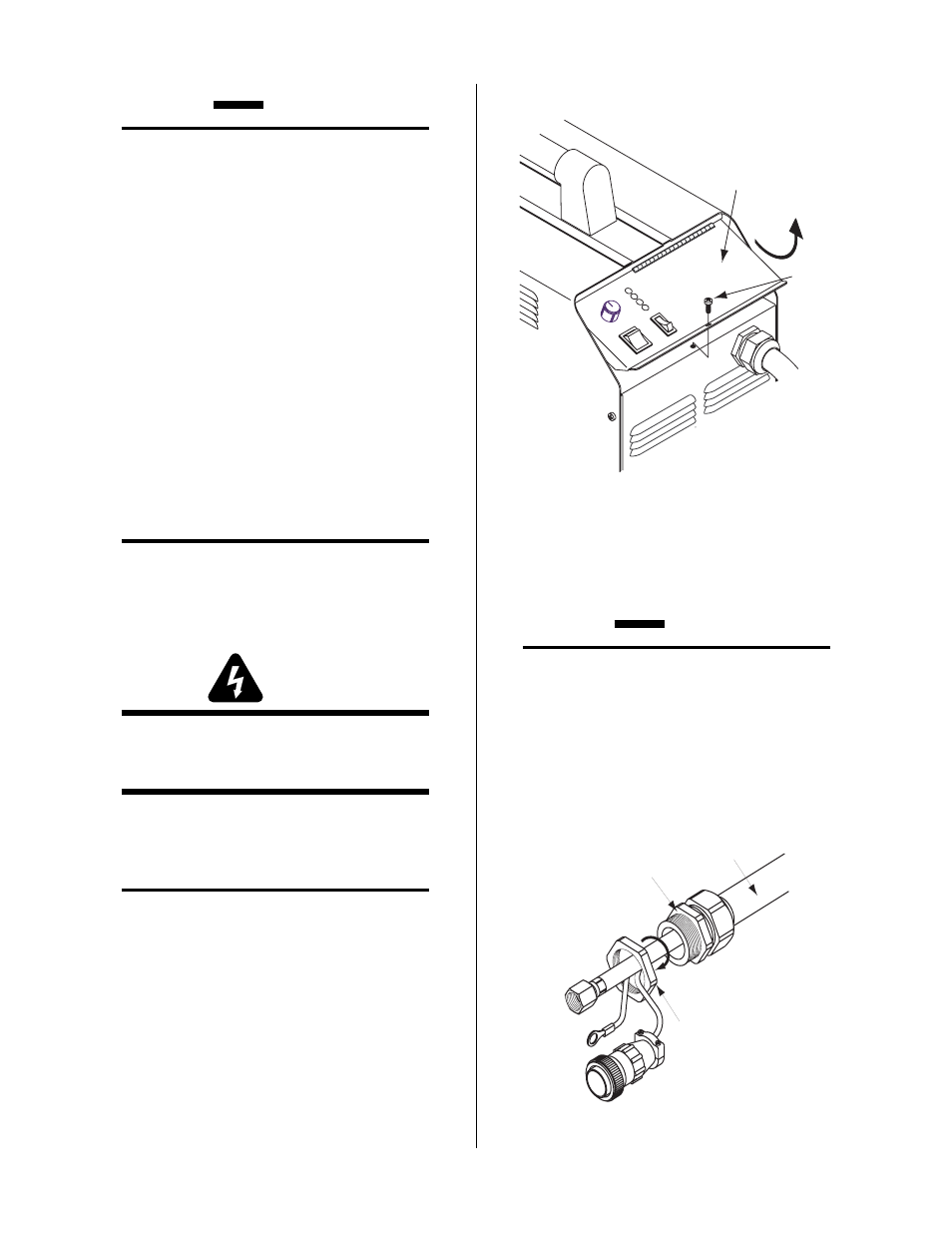

1. Turn the screw latch securing the front access panel to

the power supply front panel.

Access

Panel

Screw

Latch

A-02467

Figure 3-5 Front Access Panel

2. Lift up on the access panel to gain access to the torch

bulkhead panel.

CAUTION

This system is designed for use with the PCH/M-

80 torch only. Do not connect any other torch to

this power supply. For information about torches,

refer to Manual 0-2753.

3. Remove the Strain Relief Nut from the Strain Relief

supplied on the end of the Torch Leads.

Strain Relief

Nut

Strain Relief

Torch Leads

Assembly

A-02514

Figure 3-6 Torch Strain Relief Nut