08 work cable and ground connections – Tweco PakMaster 100XL Plus User Manual

Page 21

Manual 0-2784

15

SECTION 3: INSTALLATION PROCEDURES

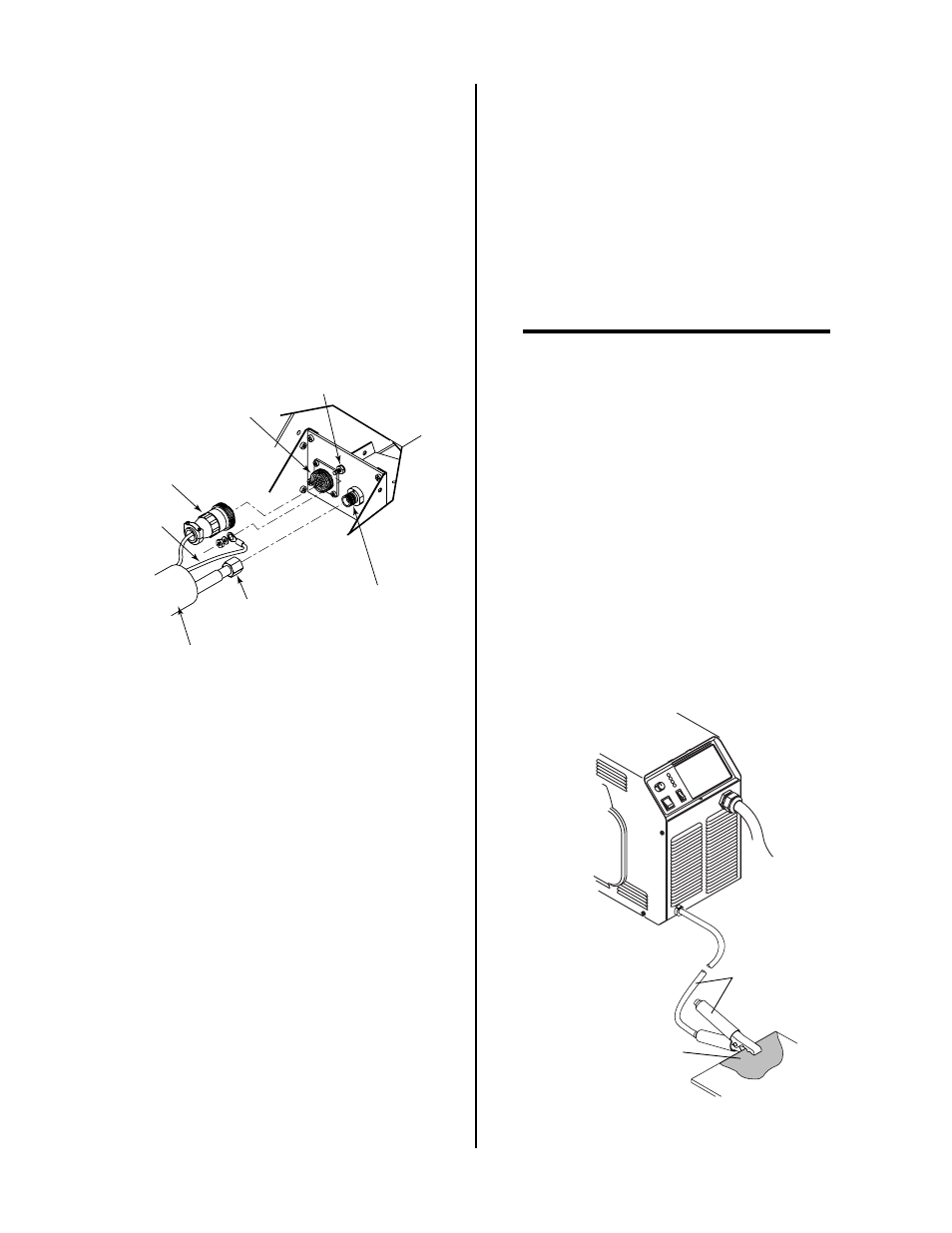

4. Feed the end of the torch leads through the hole in the

front panel in the following order:

• Control Cable

• Gas lead

• Pilot Lead

5. Place the Strain Relief Nut over the torch leads and

position it in the hole in the front panel.

6. Hold the Strain Relief Nut in position and tighten the

Strain Relief on the outside of the unit.

7. Connect the torch gas/power lead fitting onto the Gas/

Power Lead Connection.

Control Cable

Pilot Lead

Torch Lead

Assembly

Gas/Power

Lead

Control Cable

Connector

Pilot Lead Stud

Gas/Power Lead

Connection

A-00929

Figure 3-7 Torch Leads Connections

7. Connect the Torch Control Cable to the Torch Control

Connection.

8. Remove the top nut and washer from the Pilot Stud.

9. Place the lug of the Pilot Control Wire onto the stud

and secure with the nut and washer removed in Step

8.

10. Close the access panel and turn the latching screw.

3.08 Work Cable And Ground

Connections

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF may interfere with other electronic equipment

such as CNC controllers, etc. To minimize RF interfer-

ence, follow these grounding procedures when install-

ing mechanized systems:

B. Creating an Earth Ground

1. Install a ground wire (not included) between the sys-

tem and a solid earth ground (also called star ground).

To create a solid earth ground, drive a 1/2 in (12 mm)

diameter copper rod at least 6 - 8 ft (1.8 - 2.4 m) into

the earth so that the rod contacts moist soil over most

of its length. The required depth will vary depend-

ing on location (see NOTE). Locate the rod as close as

possible to the power supply. The work table should

be connected to the same earth ground as the power

supply.

NOTE

A properly installed ground rod will have a resis-

tance of one ohm or less.

2. Connect the control device (CNC) to a separate earth

ground similar to the ground rod described above.

The ground cable should be at least 12 gauge (4 mm

2

)

wire.

3. To minimize RF interference, position torch leads as

far as possible (at least 1 ft or 0.3 m) from any CNC

components, drive motors, control cables, or primary

power lines.

4. Keep torch leads clean. Dirt and metal particles bleed

off energy, which causes difficult starting and in-

creased chance of RF interference.

5. Make sure work cable and ground cables are properly

connected. The work cable must have a solid connec-

tion to the workpiece or cutting table. The connec-

tion must be free from dirt, grease, oil and paint.

A-02459

Make a solid work cable

connection to the work-

piece or cutting table

Work Cable

And Clamp

Figure 3-8 Power Supply Work Cable Connection