Tweco PakMaster 100XL Plus User Manual

Page 24

SECTION 4: OPERATION

18

Manual 0-2784

3. RUN/SET/LATCH Switch

RUN position is used for general torch operation

(torch switch must be held). SET position used for

setting pressure and purging gas lines. LATCH posi-

tion is used for specific applications (torch switch can

be released after main arc transfer).

4. AC Power Indicator

Green LED indicator will blink ON then OFF for ap-

proximately eight seconds and then stay ON after the

ON/OFF power switch is set to ON. Indicates oper-

ating power is present in the unit..

5. TEMP Indicator

Normally OFF. Yellow LED indicator will come ON

when the internal temperature sensors detect tempera-

tures above normal limits. The unit should be allowed

to cool before continuing operation.

6. GAS Indicator

Green LED indicator will come ON when the input

gas pressure is set to 45 psi (3.1 bar) or higher. Indica-

tor will be OFF when the pressure falls below 45 psi

(3.1 bar).

7. DC Indicator

Green LED indicator will come ON while the torch

switch is pressed.

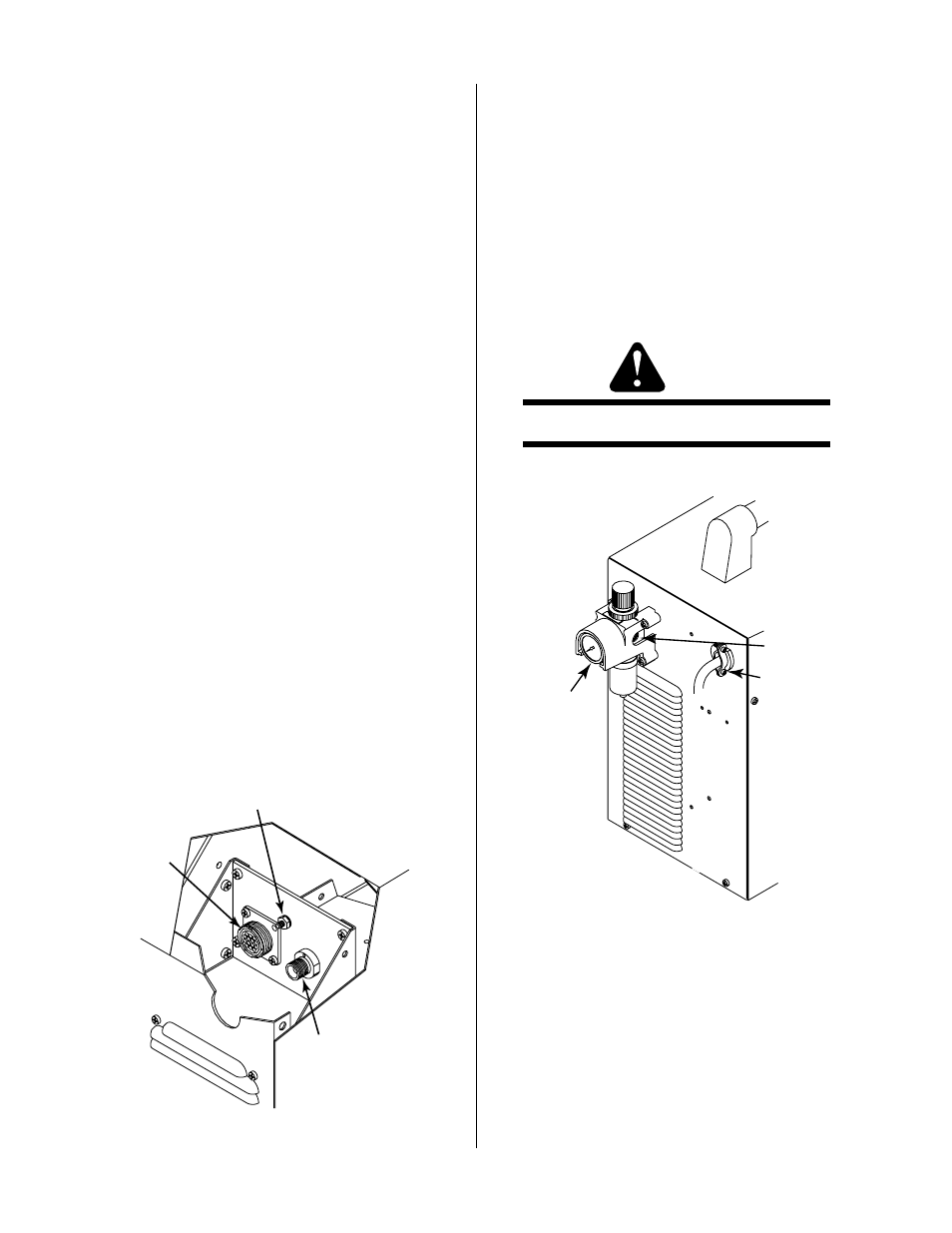

C. Torch Panel Bulkhead

The torch panel bulkhead is located under the access

panel.

1. Pilot Lead Stud

Connects the pilot control wire on the torch to the unit.

2

1

3

A-00923

Figure 4-3 Torch Panel Connections

2. Control Cable Connector

Connects the torch switch to the unit. In machine torch

applications connects the torch switch on the pendant

to the unit.

3. Gas/Power Lead Connection

Connects the torch gas/negative lead to the unit.

D. Rear Panel

1. Gas Input

Input connection for air or nitrogen (N2) input.

WARNING

This unit not to be used with oxygen (O

2

).

1

2

3

A-02605

Figure 4-4 Rear Panel

2. Primary Input Power Cable

Four-conductor Input Power Cable with filtering

beads. Three-Phase primary input power cable ca-

pable of handling the input voltage designed for this

unit. Plug is not supplied with unit.