04 sequence of operation – Tweco PakMaster 100XL Plus User Manual

Page 25

Manual 0-2784

19

SECTION 4: OPERATION

3. Gas Pressure Regulator/Filter Assembly

Pressure regulator to adjust the input gas pressure to

the Power Supply. An air line filter is supplied as part

of the pressure regulator.

4. Optional Filters

a. Dry Air Filter Assembly

This optional in-line filter removes moisture and con-

taminants from the air stream when using compressed

air. The filter is capable of filtering to at least .85 mi-

crons.

A-02607

1/4 NPT to

#4 (6mm)

Hose Fitting

Dry Air Filter

Assembly

#4 (6mm)

Gas Supply

Hose

Hose Clamp

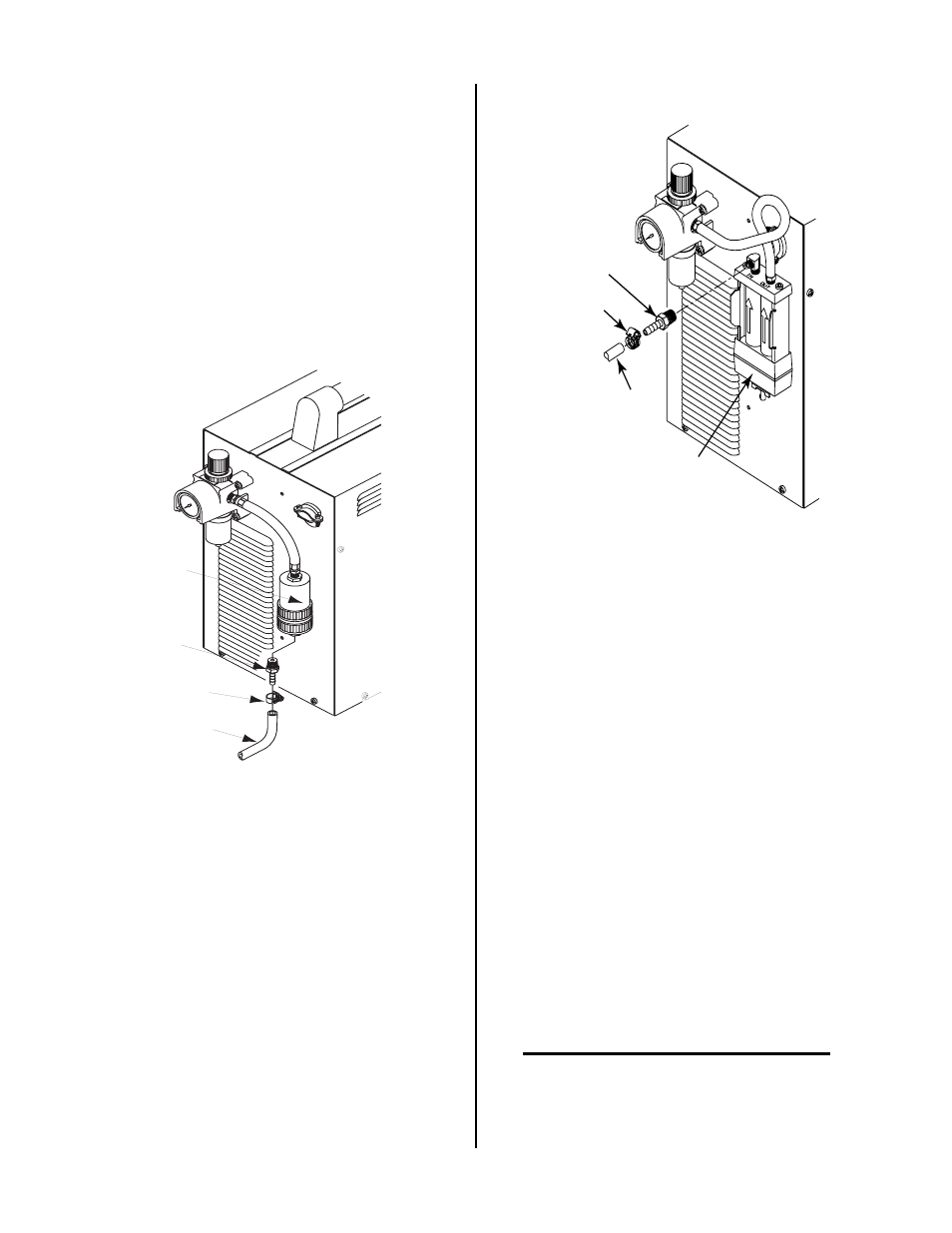

Figure 4-5 Rear Panel Showing Dry Air Filter

b. Two Stage Air Line Filter

An alternative to the Dry Air Filter, this optional filter

will remove moisture and contaminants from the air

stream when using compressed air. This filter is ca-

pable of filtering to 5.0 microns.

Two Stage Filter

Assembly

1/4 NPT to

#4 (6mm) Hose

Fitting

#4 (6mm) Gas

Supply Hose

Hose Clamp

A-01150

Figure 4-6 Rear Panel Showing Two Stage Filter

4.04 Sequence Of Operation

The following is a typical sequence of operation for this

cutting system. Refer to Appendix II for a block diagram.

1. Close main power source disconnect.

a. AC power is available at the Power Supply.

2. Place RUN/SET/LATCH switch to RUN mode.

3. Place the ON/OFF power switch on the front panel

of the Power Supply to ON.

a. AC Power indicator LED blinks ON and OFF

for eight seconds then stays ON.

b. Fans turn on.

4. Place RUN/SET/LATCH switch to SET mode.

a. Gas solenoid opens and gas flows to set pres-

sure.

b. GAS indicator turns ON.

NOTE

GAS indicator will not come ON if the gas pres-

sure is set below 35 psi (2.4 bar) at the Regulator/

Filter Assembly.