4t.06 mechanized torch operation, 4t.06 mechanized torch operation t-7, Cutmaster 35mm, 40mm – Tweco CutMaster 35mm 40mm User Manual

Page 39

CUTMASTER 35mm, 40mm

Manual 0-5118 4T-7 OPERATION

Torch Travel Speed

NOTE

Refer to Appendix Pages for additional

information as related to the Power Supply

used.

Optimum torch travel speed is dependent on cur-

rent setting, lead angle, and mode of operation

(hand or machine torch).

Current Setting

Current settings depend on torch travel speed,

mode of operation (hand or machine torch), and

the amount of material to be removed.

Pressure Setting

Even though the setting is within the specified

range, if the torch does not pilot well the pressure

may need to be reduced.

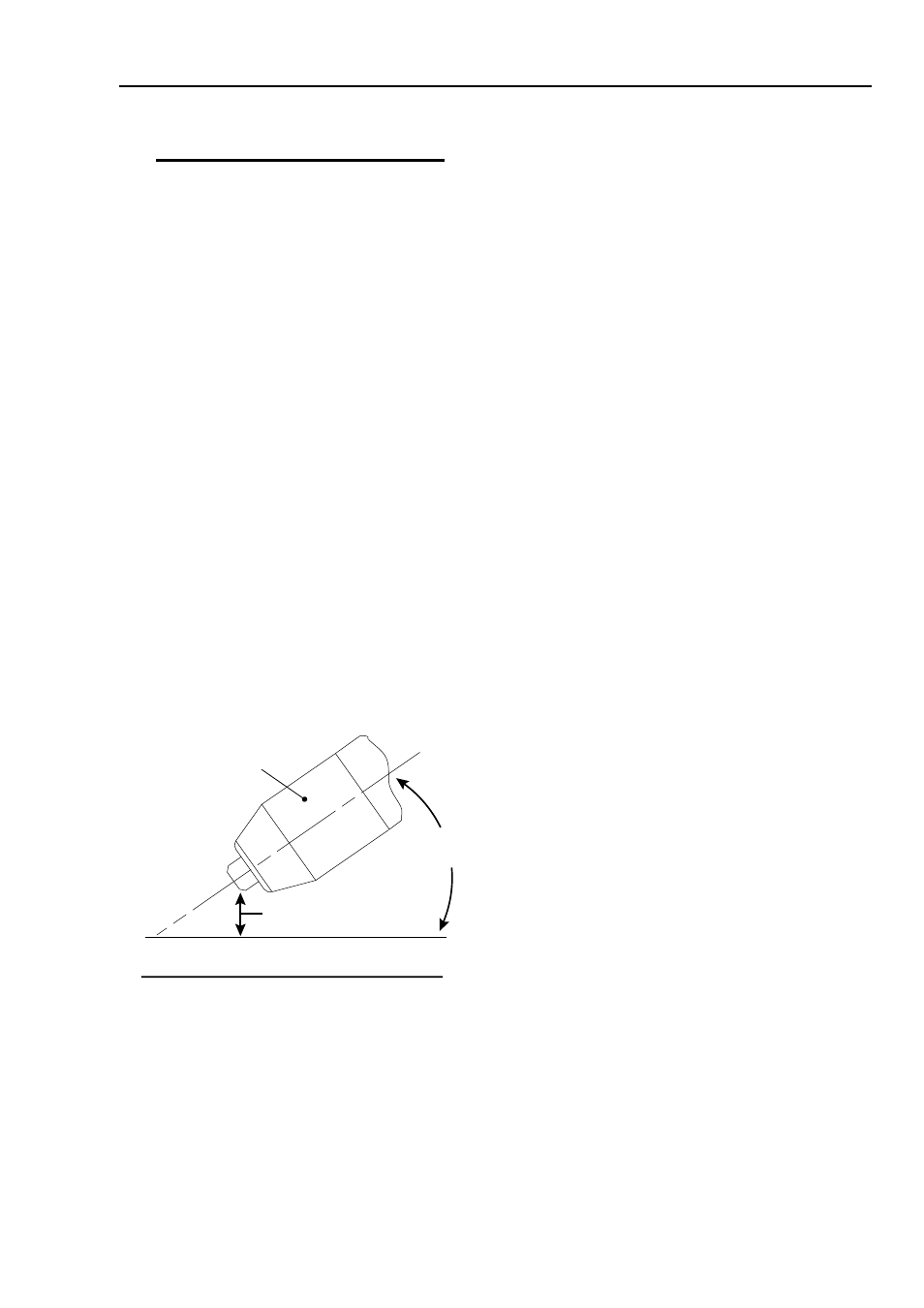

Lead Angle

The angle between the torch and workpiece de-

pends on the output current setting and torch

travel speed. The recommended lead angle is

35°. At a lead angle greater than 45° the molten

metal will not be blown out of the gouge and may

be blown back onto the torch. If the lead angle

is too small (less than 35°), less material may be

removed, requiring more passes. In some appli-

cations, such as removing welds or working with

light metal, this may be desirable.

35°

Workpiece

Torch Head

Standoff Height

A-00941_AB

Gouging Angle and Standoff Distance

Standoff Distance

The tip to work distance affects gouge quality and

depth. Standoff distance of 1/8 - 1/4 inch (3 - 6

mm) allows for smooth, consistent metal removal.

Smaller standoff distances may result in a sever-

ance cut rather than a gouge. Standoff distances

greater than 1/4 inch (6 mm) may result in mini-

mal metal removal or loss of transferred main arc.

Slag Buildup

Slag generated by gouging on materials such as

carbon and stainless steels, nickels, and alloyed

steels, can be removed easily in most cases. Slag

does not obstruct the gouging process if it accumu-

lates to the side of the gouge path. However, slag

build - up can cause inconsistencies and irregular

metal removal if large amounts of material build

up in front of the arc. The build - up is most often

a result of improper travel speed, lead angle, or

standoff height.

4T.06 Mechanized Torch Operation

Cutting With Mechanized Torch

The mechanized torch can be activated by remote

control pendant or by a remote interface device

such as CNC.

1. To start a cut at the plate edge, position

the center of the torch along the edge of

the plate.

Travel Speed

Proper travel speed is indicated by the trail of the

arc which is seen below the plate. The arc can be

one of the following:

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended

for the best cut using air plasma on stainless

or aluminum.

2. Leading Arc

The leading arc is directed in the same direc-

tion as torch travel. A five degree leading arc

is generally recommended for air plasma on

mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direc-

tion as torch travel.