4t.04 hand torch operation, 4t.04 hand torch operation t-3, Cutmaster 35mm, 40mm – Tweco CutMaster 35mm 40mm User Manual

Page 35

CUTMASTER 35mm, 40mm

Manual 0-5118 4T-3 OPERATION

Direction of Cut

In the torches, the plasma gas stream swirls as it

leaves the torch to maintain a smooth column of

gas. This swirl effect results in one side of a cut

being more square than the other. Viewed along

the direction of travel, the right side of the cut is

more square than the left.

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Side Characteristics Of Cut

To make a square - edged cut along an inside

diameter of a circle, the torch should move coun-

terclockwise around the circle. To keep the square

edge along an outside diameter cut, the torch

should travel in a clockwise direction.

Dross

When dross is present on carbon steel, it is com-

monly referred to as either “high speed, slow

speed, or top dross”. Dross present on top of

the plate is normally caused by too great a torch

to plate distance. "Top dross" is normally very

easy to remove and can often be wiped off with

a welding glove. "Slow speed dross" is normally

present on the bottom edge of the plate. It can vary

from a light to heavy bead, but does not adhere

tightly to the cut edge, and can be easily scraped

off. "High speed dross" usually forms a narrow

bead along the bottom of the cut edge and is very

difficult to remove. When cutting a troublesome

steel, it is sometimes useful to reduce the cutting

speed to produce "slow speed dross". Any resul-

tant cleanup can be accomplished by scraping,

not grinding.

4T.04 Hand Torch Operation

Standoff Cutting With Hand Torch

NOTE

For best performance and parts life,

always use the correct parts for the type of

operation.

1. The torch can be comfortably held in

one hand or steadied with two hands.

Position the hand to press the Trigger on

the torch handle. With the hand torch,

the hand may be positioned close to the

torch head for maximum control or near

the back end for maximum heat protec-

tion. Choose the holding technique that

feels most comfortable and allows good

control and movement.

NOTE

The tip should never come in contact with

the workpiece except during drag cutting

operations.

2. Depending on the cutting operation, do one

of the following:

a. For edge starts, hold the torch perpen-

dicular to the workpiece with the front

of the tip on the edge of the workpiece

at the point where the cut is to start.

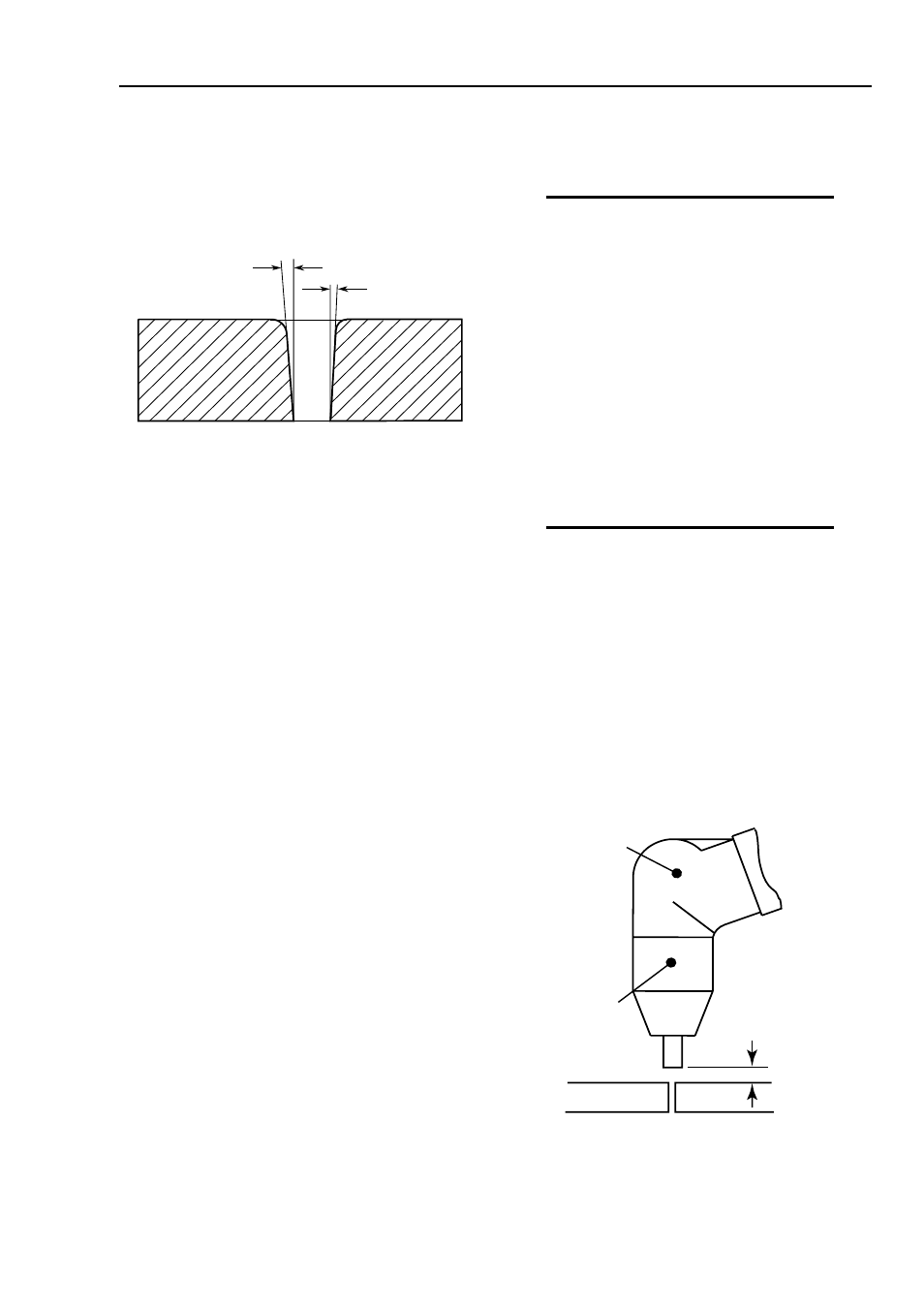

b. For standoff cutting, hold the torch 1/8

- 3/8 in (3-9 mm) from the workpiece

as shown below.

A-00024_AB

Shield Cup

Torch

Standoff Distance

1/8" - 3/8" (3 - 9mm)

Standoff Distance