57 table 39 — wshp troubleshooting (cont) – Carrier AQUAZONE PSV User Manual

Page 57

57

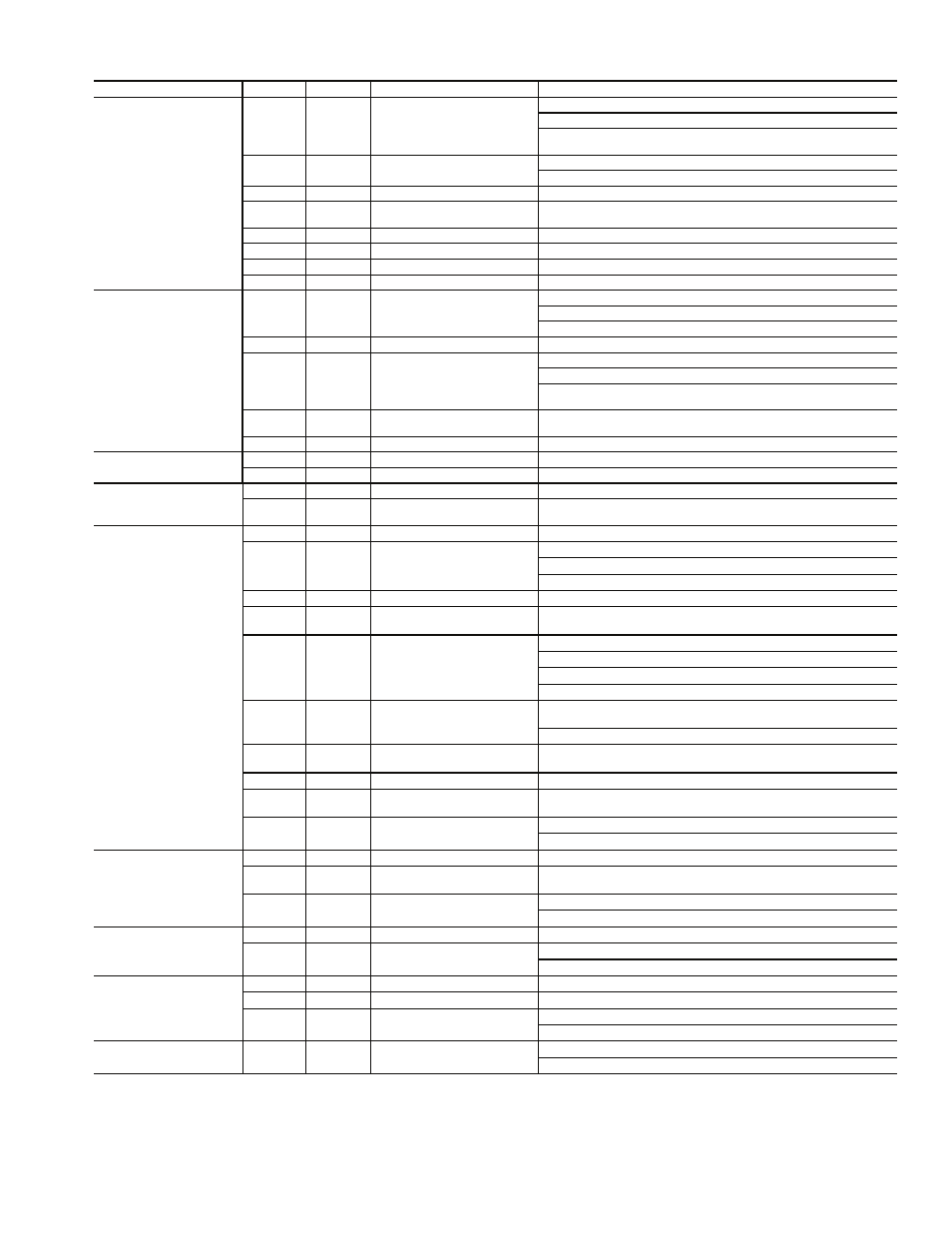

Table 39 — WSHP Troubleshooting (cont)

LEGEND

FAULT

HEATING

COOLING

POSSIBLE CAUSE

SOLUTION

High Head Pressure

X

Reduced or no airflow in

heating

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower performance per

Tables 11-13.

X

Reduced or no water flow in cool-

ing

Check pump operation or valve operation/setting.

Check water flow adjust to proper flow rate. See Tables 19 and 31.

X

Inlet water too hot

Check load, loop sizing, loop backfill, ground moisture.

X

Air temperature out of range in

heating

Bring return-air temperature within design parameters.

X

Scaling in water heat exchanger

Perform condenser cleaning.

X

X

Unit overcharged

Check superheat and subcooling. Reweigh in charge.

X

X

Noncondensables in system

Remove refrigerant, evacuate system and charge unit.

X

X

Restricted metering device

Check superheat and subcooling per Tables 20-30. Replace.

Low Suction Pressure

X

Reduced water flow in

heating

Check pump operation or water valve operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

X

Water temperature out of range

Bring water temperature within design parameters.

X

Reduced airflow in cooling

Check for dirty air filter and clean or replace.

Check fan motor operation and airflow restrictions.

External static too high. Check blower performance per

Tables 11-13.

X

Air temperature out of range

Too much cold vent air. Bring entering air temperature within design

parameters.

X

X

Insufficient charge

Check for refrigerant leaks.

Low Discharge Air

Temperature in Heating

X

Too high airflow

Check blower performance per Tables 11-13.

X

Poor performance

See “Insufficient Capacity.”

High Humidity

X

Too high airflow

Check blower performance per Tables 11-13.

X

Unit oversized

Recheck loads and sizing check sensible cooling load and heat pump

capacity.

Low Refrigerant Suction

Pressure

X

Normal operation

Check/compare with Tables 20-30.

X

Reduced water flow

Check pump operation.

Check strainer or filter.

Improper flow regulator. Replace flow regulator.

X

Water temperature out of range Bring water temperature within proper range.

X

Scaling in water to refrigerant

heat exchanger

Conduct water quality analysis.

X

Reduced airflow

Check for dirty air filter.

Check for dirty air coil.

Check fan motor operation.

External static pressure exceeds fan operating parameters.

X

X

Return air temperature below

minimum

Space temperature too cold. Increase space temperature.

Excessive fresh air. Reduce amount of fresh air exposure.

X

Supply air bypassing to return

airstream (zone systems)

Check for leaking ductwork.

X

X

Insufficient refrigerant charge

Locate and repair leak.

X

X

Improperly located TXV sens-

ing bulb

Locate bulb on suction line between reversing valve and compressor.

X

X

Failed or restricted metering

device

Failed TXV power head, capillary or sensing bulb. Replace.

Plugged TXV strainer. Unplug TXV strainer.

High Refrigerant

Superheat

X

X

Insufficient refrigerant charge

Locate and repair leak.

X

X

Improperly located TXV sens-

ing bulb

Locate bulb on suction line between reversing valve and compressor.

X

X

Failed or restricted metering

device

Failed TXV power head, capillary or sensing bulb. Replace.

Plugged TXV strainer. Unplug TXV strainer.

High Refrigerant

Subcooling

X

X

Excessive refrigerant charge

Remove refrigerant as needed.

X

X

Failed or restricted metering

device

Failed TXV power head, capillary or sensing bulb. Replace.

Plugged TXV strainer. Unplug TXV strainer.

TXV and/or Low Pressure

Tubing Frosting

X

Normal operation

May occur when entering water temperature is close to minimum.

X

X

Insufficient refrigerant charge

Locate and repair leak.

X

X

Failed or restricted metering

device

Failed TXV power head, capillary or sensing bulb. Replace.

Plugged TXV strainer. Unplug TXV strainer.

Equalizer Line

Condensing or Frosting

X

X

Failed or restricted metering

device

Failed TXV power head, capillary or sensing bulb. Replace.

Plugged TXV strainer. Unplug TXV strainer.

LED

— Light-Emitting Diode

RV

— Reversing Valve

TXV

— Thermostatic Expansion Valve