Caution – Carrier AQUAZONE PSV User Manual

Page 52

52

See Tables 37-39 for additional troubleshooting

information.

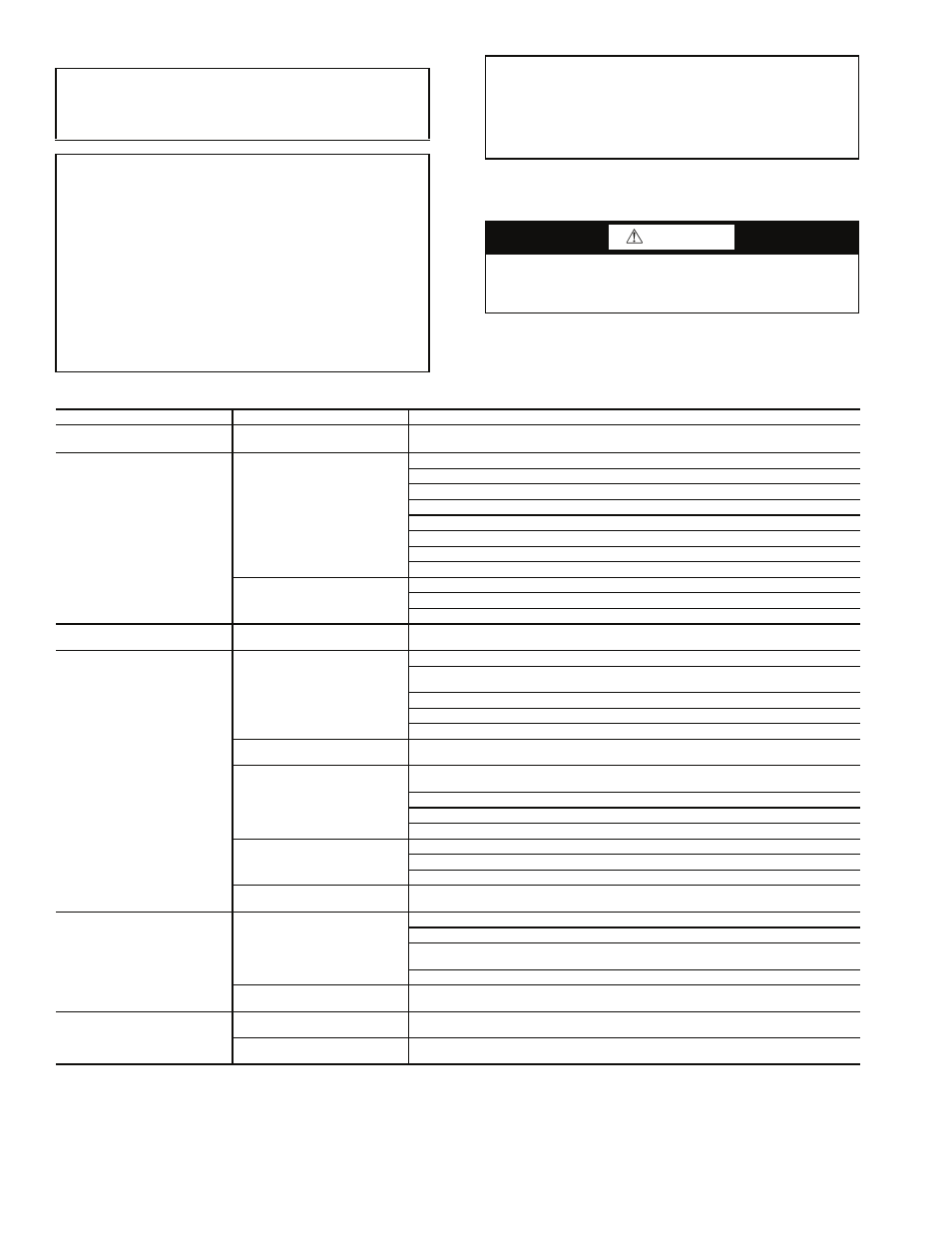

Table 37 — ECM Troubleshooting

IMPORTANT: Always recover the refrigerant from the

system with suitable approved tools, recovery equipment,

and practices prior to attempting to remove or repair any

TXV.

IMPORTANT: Due to the hygroscopic nature of the

POE oil in Puron refrigerant (R-410A) and other environ-

mentally sound refrigerants, any component replace-

ment must be conducted in a timely manner using

caution and proper service procedure for these types of

refrigerants. A complete installation instruction will be

included with each replacement TXV/filter drier assem-

bly. It is of critical importance these instructions are

carefully understood and followed. Failure to follow

these instructions can result in a system that is contami-

nated with moisture to the extent that several filter drier

replacements may be required to properly dry the

system.

IMPORTANT: Repair of any sealed refrigerant system

requires training in the use of refrigeration tools and proce-

dures. Repair should only be attempted by a qualified ser-

vice technician. A universal refrigerant handling certificate

will be required. Local and/or state license or certificate

may also be required.

CAUTION

Disconnect power from unit before removing or replacing

connectors, or servicing motor. Wait 5 minutes after dis-

connecting power before opening motor.

FAULT

DESCRIPTION

SOLUTION

Motor rocks slightly when

starting

This is normal start-up for ECM.

Motor will not start

No movement

Check power at motor.

Check low voltage (24-vac R to C) at motor.

Check low voltage connections (G,Y, W, R, C) at motor.

Check for unseated pins in connectors on motor harness. See Fig. 40.

Test with a temporary jumper between R and G.

Check motor for tight shaft.

Perform motor/control replacement check.

Run moisture check. See Moisture Check section in Troubleshooting.

Motor rocks

Check for loose or non-compliant motor mount.

Make sure blower wheel is tight on shaft.

Perform motor/control replacement check.

Motor oscillates up and down

while being tested off of blower

It is normal for motor to oscillate with no load on shaft.

Motor starts, but runs erratically Varies up and down or intermittent

Check line voltage for variation or “sag.”

Check low voltage connections (G,Y, W, R, C) at motor, unseated pins in motor harness

connectors. See Fig. 40.

Check “Bk” for erratic cfm command (in variable speed applications).

Check system controls, thermostat.

Perform moisture check. See Moisture Check section in Troubleshooting.

“Hunts” or “puffs” at high cfm

(speed)

If removing panel or filter reduces “puffing,” reduce restriction or reduce maximum airflow.

Stays at low cfm despite system

call for cool or heat cfm

Check low voltage (thermostat) wires and connections.

Verify fan is not in delay mode. Wait until delay is complete.

Check to see if “R” is missing/not connected at motor.

Perform motor/control replacement check.

Stays at high cfm

Check to see if “R” is missing/not connected at motor.

Verify fan is not in delay mode. Wait until delay is complete.

Perform motor/control replacement check.

Blower will not shut off

Check to see if there is current leakage from controls into G, Y, or W. Check for Triac switched

thermostat or solid state relay.

Excessive noise

Noisy blower or cabinet

Determine if it is air, cabinet, duct, or motor noise.

Check for loose blower housing, panels, etc.

If high static is creating high blower speed, check for air whistling through seams in ducts,

cabinets, or panels.

If high static is creating high blower speed, check for cabinet/duct deformation.

“Hunts” or “puffs” at high cfm

(speed)

If removing panel or filter reduces “puffing,” reduce restriction or reduce maximum airflow.

Evidence of moisture

Motor failure or malfunction has

occurred and moisture is present

Replace motor and perform moisture check. See Moisture Check section in Troubleshooting.

Evidence of moisture present

inside air mover

Perform moisture check. See Moisture Check section in Troubleshooting.