Cleaning, Dip switch settings – tekmar 667 Snow Detector & Melting Control Installation User Manual

Page 18

18 of 32

©

2009 D

667

-

03/09

System Pump (System Pmp 2)

If a pump is connected to the System Pmp 2 terminals (17 and 18), make sure power to the pump circuit is off and install a

jumper between the System Pmp 2 terminals (17 and 18). When the circuit is powered up, the pump should turn on. If no

response occurs, check the wiring between the terminal and the pump and refer to any installation or troubleshooting

information supplied with the pump. If the pump operates properly, disconnect the power and remove the jumper.

Boiler

If the boiler circuit is connected to the Boiler terminals (19 and 20), make sure power to the boiler circuit is off, and install

a jumper between the terminals. When the boiler circuit is powered up, the boiler should fire. If the boiler does not turn

on, refer to any installation or troubleshooting information supplied with the boiler. (The boiler may have a flow switch

that prevents firing until the boiler pump is running). If the boiler operates properly, disconnect the power and remove the

jumper.

Melting

If a device is connected to the Melting terminals (21 and 22), make sure power to the circuit is off, and install a jumper

between the terminals. When the circuit is powered up, the device should operate. If the device does not operate, refer

to any installation or troubleshooting information supplied with the device. If the device operates properly, disconnect the

power and remove the jumper.

Variable Speed Injection Pump

If a variable speed injection pump circuit is connected to the Var and Com terminals (1 and 2), make sure the power to the

terminal block is off and install a jumper between the Var and Com terminals (1 and 2). When the variable speed pump

circuit is powered up, the variable speed pump should operate at full speed. If the pump does not operate, check the

wiring between the terminal block and the pump and refer to any installation or troubleshooting information supplied with

22

23

Sys

P1

25

21

Melting

Power

L

N

24

Cleaning

The control’s exterior can be cleaned using a damp cloth. Moisten cloth with water and wring out prior to wiping control. Do no use

solvents or cleaning solutions.

DIP Switch Settings

The DIP switch settings on the control are very important and should be set to the appropriate

settings prior to making an adjustments to the control through the User Inter-face. The DIP

switch settings change the items that are available to be viewed and / or adjusted in the User

Interface.

If a DIP switch is changed while the control is powered up, the control responds to the change

in setting by returning the display to the VIEW menu. This is true for all the DIP switches

except for the Lock / Unlock DIP switch.

Idle Demand

Melt Demand

the pump. If the pump operates properly, disconnect the power and

remove the jumper.

Connecting The Control

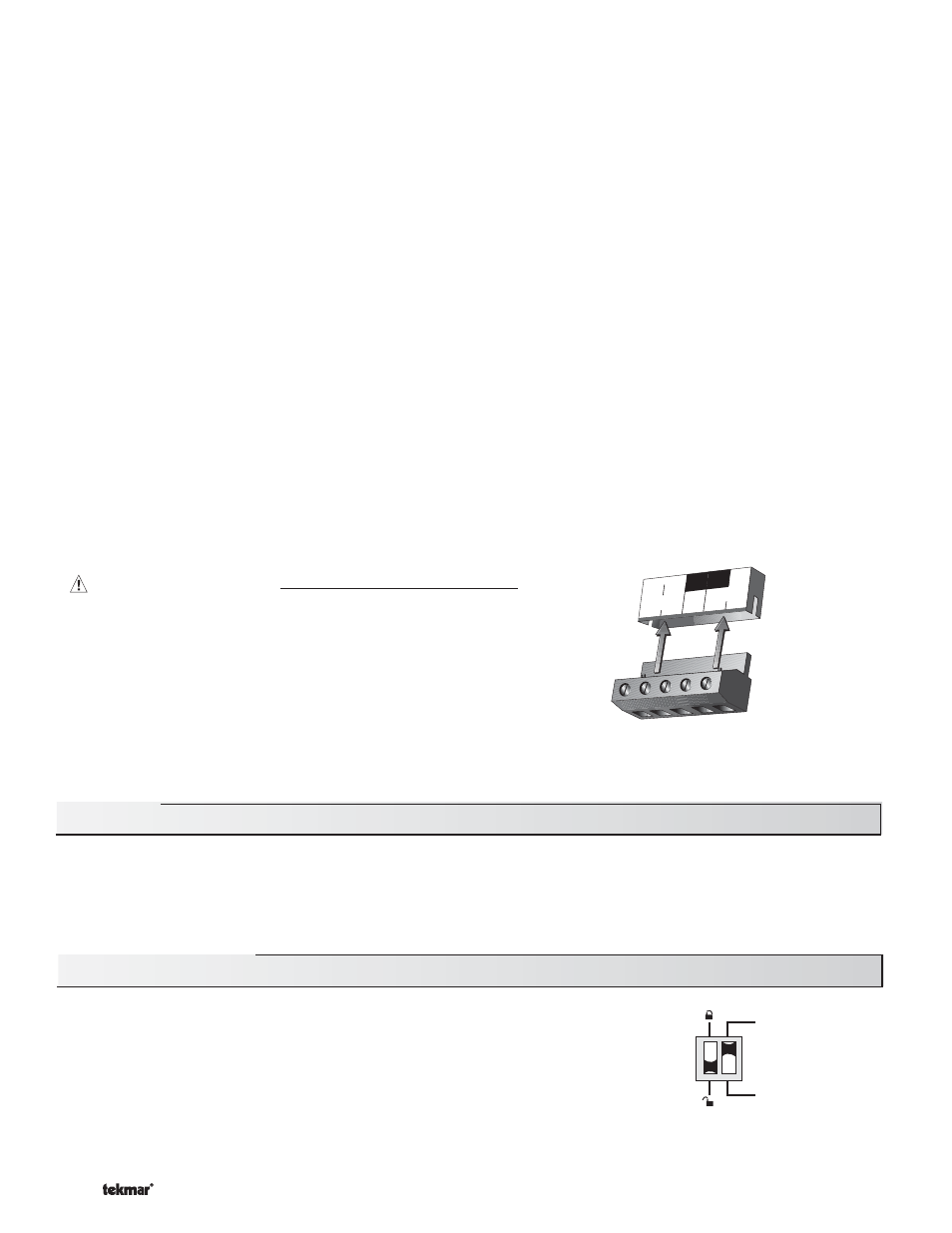

Make sure all power to the devices and terminal blocks is off, and

remove any remaining jumpers from the terminals.

Reconnect the terminal blocks to the control by carefully aligning

them with their respective headers on the control, and then pushing

the terminal blocks into the headers. The terminal blocks should snap

fi rmly into place.

Install the supplied safety dividers between the unpowered sensor

inputs and the powered wiring chambers.

Apply power to the control. The operation of the control on power up is

described in the Sequence of Operation section of the brochure.