tekmar 665 Snow Detector & Melting Control Installation User Manual

Page 14

14 of 28

©

2012 D

665

-

04/12

tekmarNet

®

(tN2) Device

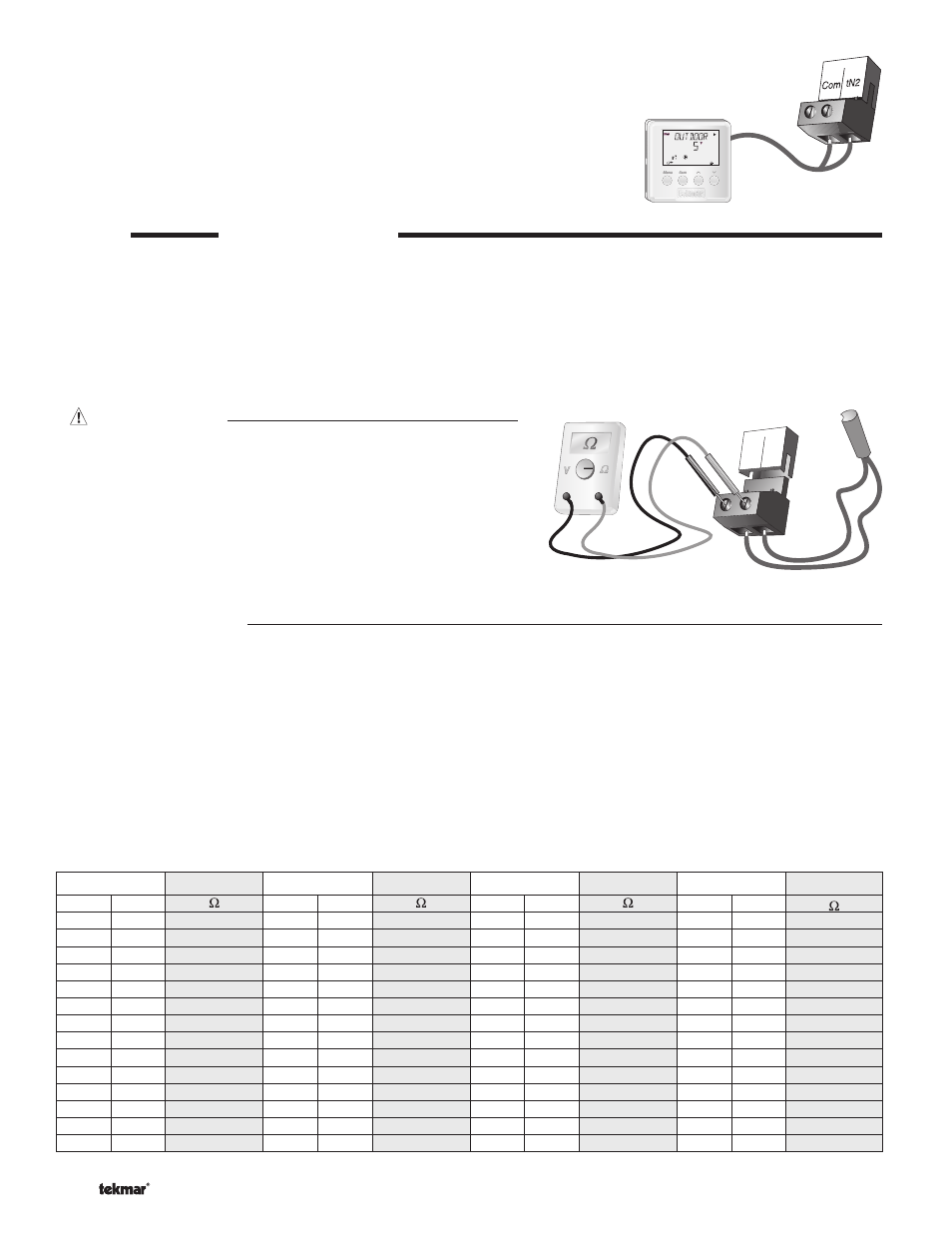

A Remote Display Module (RDM) 040 or Remote Start / Stop Module 039 can be

connected to the tekmarNet

®

(tN2) input. Connect the Com terminal from the

appropriate tN2 device to the Com terminal (7) on the 665. Connect the tN2 terminal from

the appropriate tN2 device to the tN2 terminal (8) on the 665.

Note: The wires from the RDM and Remote Start / Stop Module are polarity sensitive.

The tN2 device does not operate correctly if the wires are reversed.

7 8

7

Com

6

Out

STEP SIX

TESTING THE WIRING

Each terminal block must be unplugged from its header on the control before power is applied for testing. To remove the terminal

block, pull straight down from the control.

The following tests are to be performed using standard testing practices and procedures and should only be carried out by properly

trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 – 300 V (ac) and at least 0 – 2,000,000 Ω, is essential to

properly test the wiring and sensors.

Test the Sensors

In order to test the sensors, the actual temperature at each sensor

location must be measured. A good quality digital thermometer with

a surface temperature probe is recommended for ease of use and

accuracy. Where a digital thermometer is not available, a spare

sensor can be strapped alongside the one to be tested and the

readings compared.

Temperature

Resistance

Temperature

Resistance

Temperature

Resistance

Temperature

Resistance

°F

°C

°F

°C

°F

°C

°F

°C

-50

-46

490,813

20

-7

46,218

90

32

7,334

160

71

1,689

-45

-43

405,710

25

-4

39,913

95

35

6,532

165

74

1,538

-40

-40

336,606

30

-1

34,558

100

38

5,828

170

77

1,403

-35

-37

280,279

35

2

29,996

105

41

5,210

175

79

1,281

-30

-34

234,196

40

4

26,099

110

43

4,665

180

82

1,172

-25

-32

196,358

45

7

22,763

115

46

4,184

185

85

1,073

-20

-29

165,180

50

10

19,900

120

49

3,760

190

88

983

-15

-26

139,403

55

13

17,436

125

52

3,383

195

91

903

-10

-23

118,018

60

16

15,311

130

54

3,050

200

93

829

-5

-21

100,221

65

18

13,474

135

57

2,754

205

96

763

0

-18

85,362

70

21

11,883

140

60

2,490

210

99

703

5

-15

72,918

75

24

10,501

145

63

2,255

215

102

648

10

-12

62,465

80

27

9,299

150

66

2,045

220

104

598

15

-9

53,658

85

29

8,250

155

68

1,857

225

107

553

A good quality test meter capable of measuring up to 5,000 kΩ (1 kΩ = 1000 Ω) is required to measure the sensor resistance. In

addition to this, the actual temperature must be measured with either a good quality digital thermometer, or if a thermometer is

not available, a second sensor can be placed alongside the one to be tested and the readings compared.

First measure the temperature using the thermometer and then measure the resistance of the sensor at the control. The wires

from the sensor must not be connected to the control while the test is performed. Using the chart below, estimate the temperature

measured by the sensor. The sensor and thermometer readings should be close. If the test meter reads a very high resistance,

there may be a broken wire, a poor wiring connection or a defective sensor. If the resistance is very low, the wiring may be

shorted, there may be moisture in the sensor or the sensor may be defective. To test for a defective sensor, measure the

resistance directly at the sensor location.

Do not apply voltage to a sensor at any time as damage to the sensor may result.

Test the Sensor Wiring