Boiler differential (boil diff), No boiler sensor, Boiler enable ( 30% enable / 10% enable ) – tekmar 360 Mixing Control User Manual

Page 9

9 of 20

© 2009 D 360 - 03/09

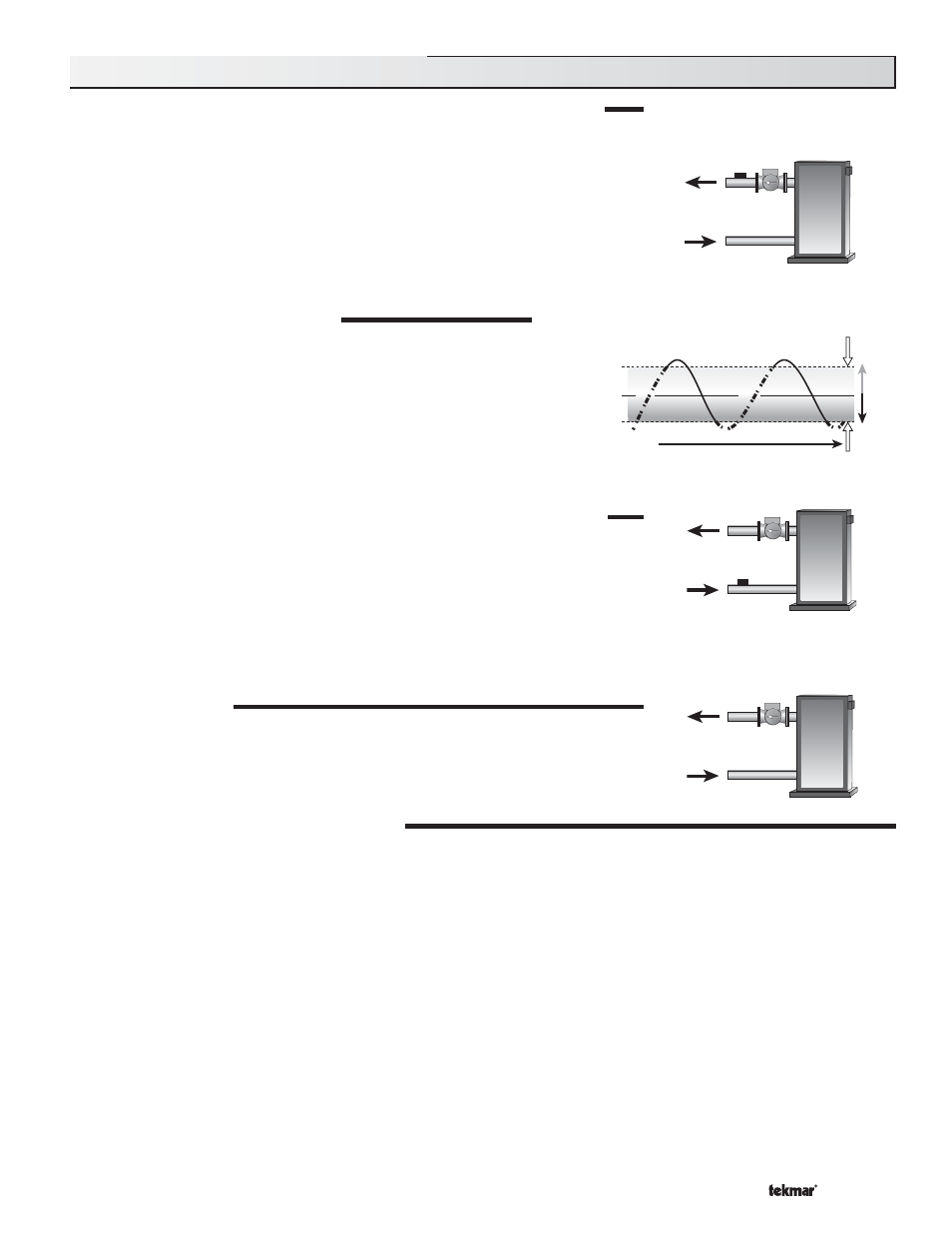

BOILER SENSOR ON THE SUPPLY (Boiler Sensor DIP switch = Supply)

The boiler sensor can be located on the boiler supply if the 360 is the only control that is

operating the boiler. When in the supply mode, the 360 determines the required operating

temperature of the boiler using Boiler Load Reset. With Boiler Load Reset, the 360 oper-

ates the boiler at the lowest possible supply temperature that is sufficient to satisfy the

requirements of the mixing valve. If this mode of operation is selected, the boiler pump

should either operate continuously, or be operated in parallel with the system pump con-

tact (Sys Pmp).

Note: The boiler pump should not be operated by the boiler’s aquastat, as this may lead to

improper cycling of the boiler because of inconsistent flow past the boiler supply sensor.

BOILER DIFFERENTIAL (BOIL DIFF)

An on / off heat source such as a boiler must be operated with a differen-

tial in order to prevent short cycling. When the boiler supply temperature

drops below the bottom rail of the differential, the 360 closes the Boiler

contact to fire the boiler. When the boiler supply temperature rises above

the top rail of the differential, the 360 opens the Boiler contact to turn off

the boiler. With the 360, either a fixed or automatic differential setting is

selected. If automatic differential (Ad) is selected, the 360 automatically

adjusts the boiler differential under the current load conditions to avoid

short cycling.

BOILER SENSOR ON THE RETURN (Boiler Sensor DIP switch = Return)

The boiler sensor should be located on the boiler return if the 360 is one of many controls

that can call for boiler operation. When in the return mode, the 360 provides a boiler enable

as described in the BOILER ENABLE section. The 360 no longer tries to control the boiler

supply water temperature directly but allows the boiler to operate at its operating aquastat

setting when required. If this mode of operation is selected, the boiler pump should either

operate continuously or be operated in parallel with the system pump contact (Sys Pmp).

Note: The boiler pump should not be operated by the boiler’s aquastat, as this may lead to

improper cycling of the boiler because of inconsistent flow past the boiler return sensor.

NO BOILER SENSOR

The 360 is capable of operating without a boiler sensor if desired. Without a boiler sensor,

the 360 provides a boiler enable as described in the BOILER ENABLE section, but is

unable to provide boiler protection. This type of application is typical if the 360 is drawing

heat from a heat source that already incorporates some form of boiler protection.

BOILER ENABLE (30% Enable / 10% Enable)

The 360 has a DIP switch that allows for the selection between a 30% boiler enable and a 10% boiler enable. This switch is only

functional when the Boiler Sensor DIP switch is set to Return.

In the 30% position, the 360 closes the Boiler contact when the position of the mixing valve exceeds 30%. The Boiler contact

remains closed until the position of the mixing valve reduces below 15%. This setting would normally be chosen for low mass boil-

ers (copper fin-tube, etc.) or systems with low thermal mass in the loop between the boiler and the mixing valve.

In the 10% position, the 360 closes the Boiler contact when the position of the mixing valve exceeds 10%. The Boiler contact

remains closed until the position of the mixing valve reduces below 5%. This setting is normally chosen for high mass boilers (cast

iron, steel, fire-tube, etc.) or systems with large thermal mass in the loop between the boiler and the mixing valve.

In order to prevent short cycling, the Boiler contact has a minimum on time, and a minimum off time.

Boiler Supply

Sensor

Boiler Return

Sensor

No Boiler

Sensor

B

oi

le

r O

n

B

oi

le

r

O

n

Time

Supply W

a

ter T

e

mper

atur

e

Differential = 10°F (6°C)

165°F (74°C)

160°F (71°C)

155°F (68°C)

Section C2: Boiler Sensor Placement