Flap servo installation – E-flite P-51B Mustang 32e ARF User Manual

Page 22

22

E-flite P-51B Mustang 32e ARF Assembly Manual

18. Slide a silicone clevis retainer over a nylon

clevis. Thread the clevis on the pushrod wire. With

the radio system on and the aileron servo centered,

connect the clevis to the outer hole of the control

horn. It may be necessary to adjust the clevis so it

lines up with the control horn. Once attached, slide

the clevis retainer over the forks of the clevis to

prevent it from opening accidentally.

19. Repeat Steps 1 through 18 to install the

remaining aileron servo and linkage.

20. Remove the tape holding the flaps and ailerons

on both wing panels. Also make sure your radio

system has been turned off as to not run the

batteries down.

Flap Servo Installation

Required Parts

Wing panel (right and left)

Transmitter

Receiver

Nylon clevis (2)

Silicone clevis retainer (2)

Receiver battery

Servo with hardware (2)

2mm x 8mm sheet metal screw with shoulder (8)

3-inch (76mm) pushrod wire (2)

Required Tools and Adhesives

Thin CA

Low-tack tape

Ruler

Phillips screwdriver: #1

Side cutter

Pin vise

Felt-tipped pen

Drill bit: 5/64-inch (2mm)

Before starting the installation of the flap servos,

set the throw for the flaps to 0% in both the UP

and DOWN positions. This will center the flap

servo and allow for adjustment once the flap servo

and linkage are installed in the wing and prevent

any damage to the servo or control surface.

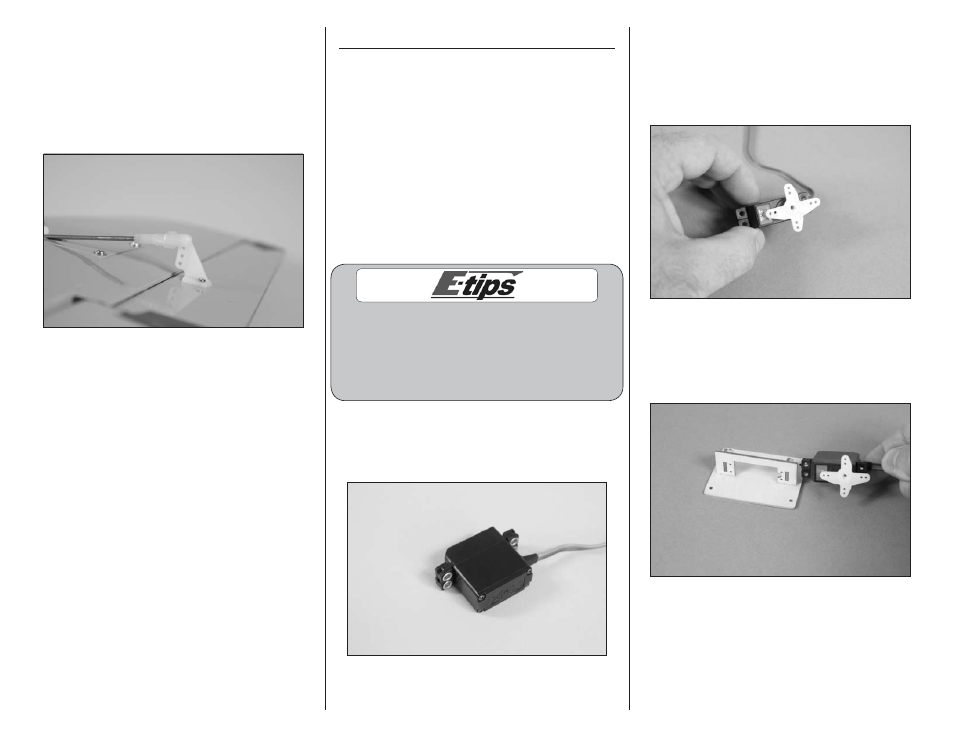

1. Prepare the flap servo by installing the

brass eyelets and rubber grommets in the servo.

Also remove the stock servo horn using a #1

Phillips screwdriver.

2. Use the radio system to center the flap servo.

Place the servo horn on the servo so the longer

portion of the arm is parallel to the servo center

line. If the horn does not align, rotate the horn

180-degrees, as there are an odd number of splines

on the servo output.

3. Check the servo in relationship to the flap servo

cover. The notch in the cover mount will be located

where the lead exits the flap servo. Use a felt-tipped

pen to mark the arm on the servo horn that faces

away from the servo cover.