Motor and cowling installation – E-flite P-51B Mustang 32e ARF User Manual

Page 12

12

E-flite P-51B Mustang 32e ARF Assembly Manual

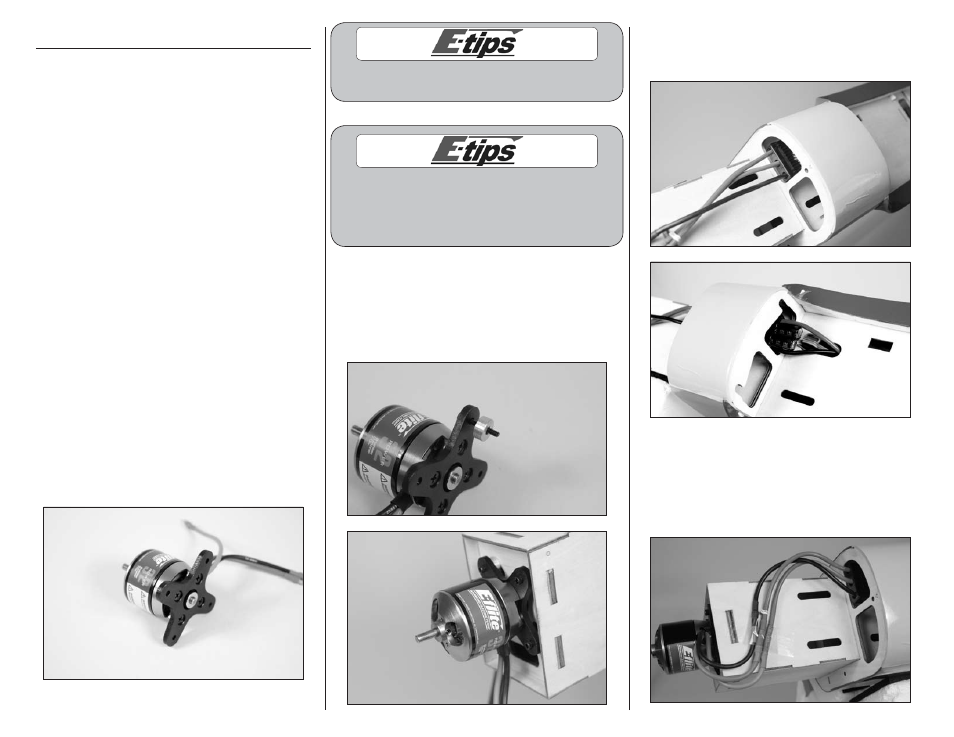

Motor and Cowling Installation

Required Parts

Fuselage

Motor with accessories

Cowling

Speed control

#4 washer (2)

Hook and loop tape

Aluminum spacer, 1/8-inch (3mm)

Hook and loop strap (2)

3/16-inch (5mm) aluminum spacer (4)

4-40 x 3/4-inch socket head machine screw (4)

4-40 x 3/8-inch socket head machine screw (8)

Required Tools and Adhesives

Threadlock

Ball driver: 3/32-inch

Scissors

Phillips screwdriver: #2

Power setups: We found the best power

system for the P-51B is the Power 32 on

4S using an APC 13 x 6.5E prop. This

delivered solid flight performance with a

very acceptable current draw. All instructions

are regarding the Power 32 setup. If using a

Power 25 4S setup, please note the change on

the spacers for proper motor placement. The

Power 25 uses the 1/8-inch (3mm) spacers

only and the Power 32 uses the 1/8-inch

(3mm) and 3/16-inch (5mm) spacers.

1. Locate the motor, X-mount and hardware to

attach the mount to the motor. Use a #2 Phillips

screwdriver to install the screws that secure the

mount to the motor.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

The blind nuts in the firewall can be positioned

for a variety of different motor options. They

will slide easily and may not be in the correct

location for any one particular motor when the

fuselage is removed from the packaging.

2. Use the four 4-40 x 3/4-inch socket head

screws, four 3/16-inch (5mm), and four 1/8-inch

(3mm) aluminum spacers to attach the motor to

the firewall. The spacers fit between the mount

and firewall. Use a 3/32-inch wrench to tighten

the screws.

3. Place the speed control in the fuselage as shown.

Route the leads through the oval hole in the battery

tray as shown in the photo.

4. Connect the motor and speed control leads. If

you are using the recommended motor and speed

control, connect the lead wires according to color

for the motor to rotate in the correct direction.

Secure the leads so they do not interfere with the

operation of the motor.