Machine safety switches, Si-ls42 series locking style switch, Electrical installation – Banner SI-QM100 Locking Style Switches User Manual

Page 6: Caution, Warning, Access to wiring chamber

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

P/N 60099 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Electrical Installation

Access to Wiring Chamber

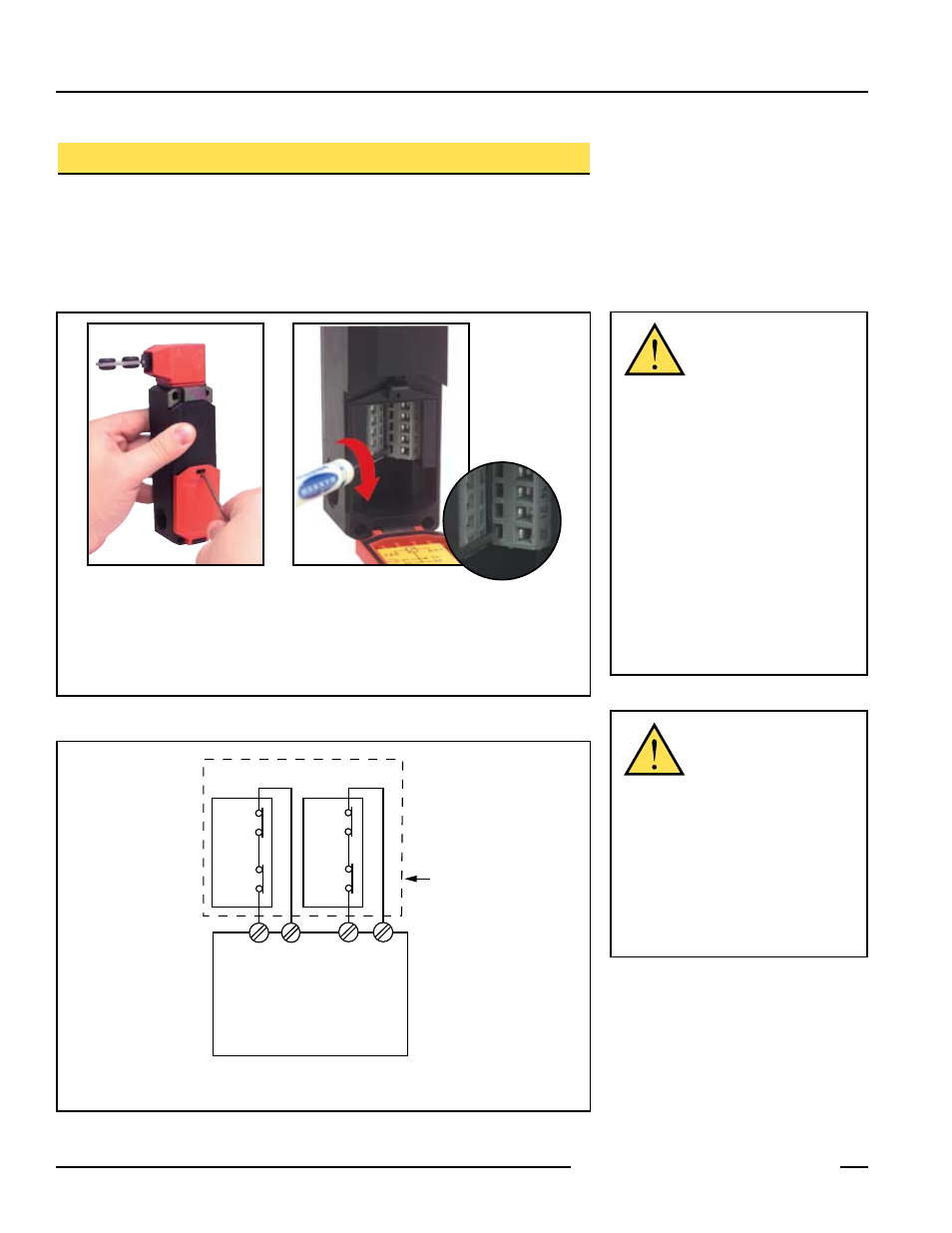

The wiring chamber is accessed via the hinged door. Simply insert a flat-blade

screwdriver, as shown in Figure 5, and pry gently down to open. Select the best wiring

entrance and thread in the ½" x 14 NPSM conduit adapter (supplied), or the optional M20

x 1.5 cable gland (page 12). The switch knockout will break loose with the final turn of

the conduit adapter or cable gland.

Figure . Access to wiring chamber – use a small flat-blade screwdriver

To connect wires to terminals:

1. Insert the screwdriver blade into the slot below the

desired wiring terminal.

2. Twist the screwdriver blade in the slot to open the

terminal jaws; insert wire.

3. Hold wire in place and remove screwdriver.

To open wiring chamber:

1. Insert the screwdriver

blade into slot in cover to

pry cover open.

Safety Switch #1

Safety Switch #2

Input

Channel

#1

Input

Channel

#2

2-channel Safety Module

(2-channel E-stop Module

2-channel Gate Monitor Module, etc.)

Single gate

or guard

Solenoid

Monitor

Contact

Solenoid

Monitor

Contact

Actuator

Safety

Contact

Actuator

Safety

Contact

Figure . Connect two redundant safety switches per interlock guard to an appropriate

2-channel input safety module.

NOTE: Refer to the installation instructions provided with the safety module for information

regarding the interface of the safety module to the machine stop control elements.

CAUTION . . .

Electrical Installation

Two safety switches

must be used for each interlock guard

to achieve control reliability or Safety

Category 4 (per ISO 1849-1, EN 94-1) of

a machine stop circuit. Use of only one

safety switch per interlock guard is not

recommended.

In addition, normally-closed safety contacts

from each of the two safety switches should

be connected to the two separate inputs of a

2-channel safety module or safety interface,

as illustrated in Figure 6. This is required to

provide monitoring for safety switch contact

failure, and to provide the necessary reset

routine, as required by IEC 60204-1 and

NFPA 79 machine safety standards.

WARNING . . .

Series

Connection of Safety

Interlock Switches

Monitoring multiple guards with a series

connection of multiple safety interlock

switches is not a Safety Category 4

Application (per ISO 1849-1, EN 94-1).

A single failure may be masked or

not detected at all. When such a

configuration is used, procedures must

be performed regularly to verify proper

operation of each switch.