Machine safety switches, Si-ls42 series locking style switch, Mechanical installation – Banner SI-QM100 Locking Style Switches User Manual

Page 5

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

P/N 60099 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Mechanical Installation

Horizontal or Vertical Actuation

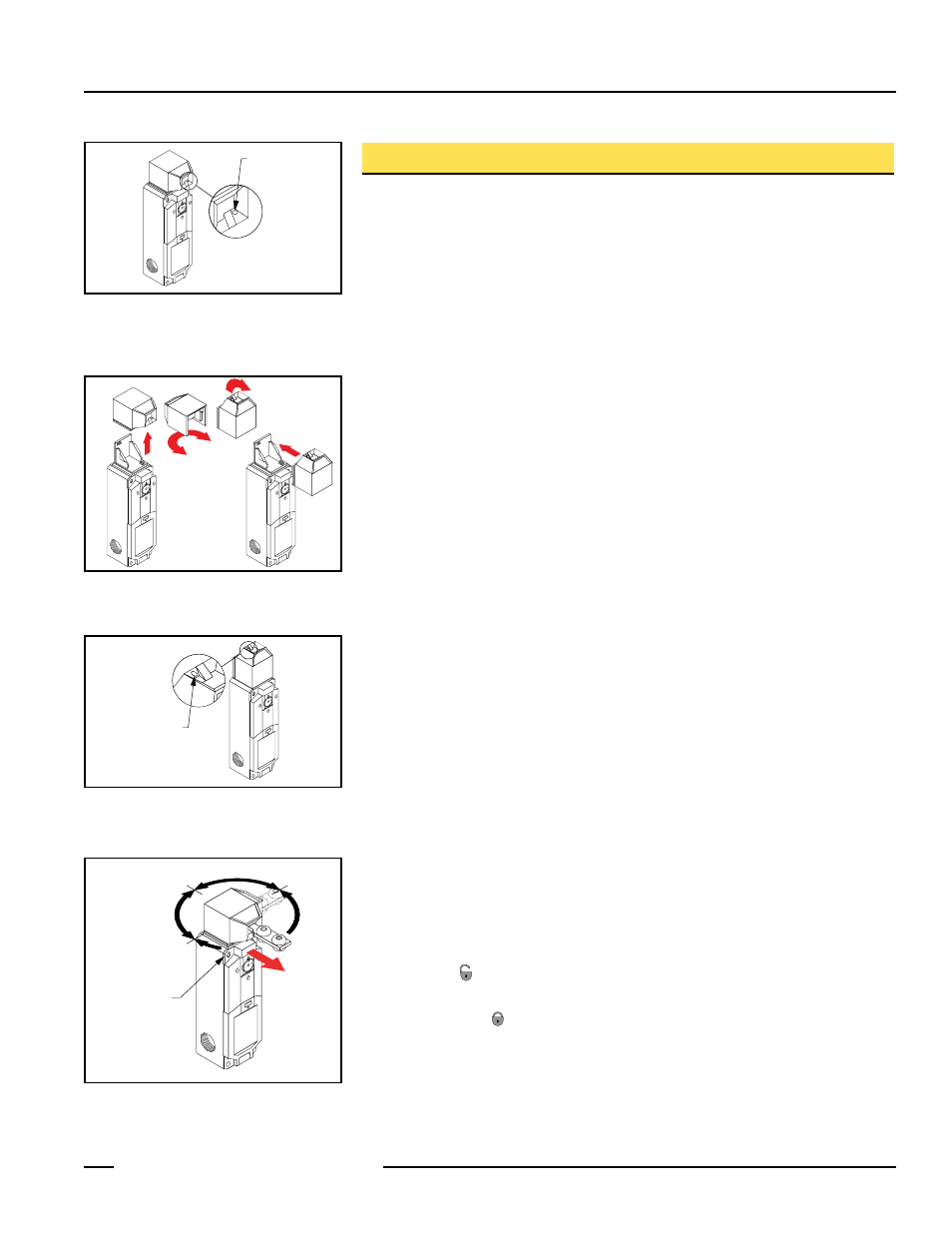

Before installation, orient the switch actuator head for either horizontal (at a right angle

to the switch length) or vertical (in-line with the switch length) actuation. The switch is

shipped with the actuator head in the horizontal position (Figure 1). If this is the desired

orientation, install the M3 x 15 mm tamper-proof (one-way) screw, which is found in a

plastic bag, stored in the wiring chamber (see page 6 for information on opening the

wiring chamber access door).

If vertical actuation is required, remove the head by pulling straight up and off (Figure 2).

Re-orient the actuator head, and slide it back on in the new position until it snaps into

place. Install the tamper-proof screw, as shown in Figure 3.

Rotating Actuator Head to Desired Position

The actuator head may be rotated in increments of 90° to create eight possible actuator

engagement positions (i.e., four horizontal plus four vertical positions). To rotate the

head, pull the holding clamp forward, rotate the head (in either direction) to the desired

position, and push the holding clamp back in to lock. The head may be rotated with the

actuator either engaged or removed (Figure 4).

Installing the Switch and Actuator

NOTE: All mounting hardware is supplied by the switch user. The fasteners must be of

sufficient strength to avoid incidental breakage. Use of permanent fasteners or

locking hardware is recommended to prevent loosening or displacement of the

actuator and switch body.

The mounting holes in the switch body accept M5 (#10) screws. There are four holes

on a mounting pattern of 30 x 124 mm (see dimension drawing of switch, page 10). See

page 11 for dimensions of the actuator mounting holes.

Position the switch, with its actuator fully engaged, at the mounting location and mark

the mounting holes. Fasten the switch body and the actuator in place. The rigid in-line

actuator includes floating sleeves in the mounting holes to allow some forgiveness for

switch-to-actuator alignment. If the rigid in-line actuator is used, take care to not over-

tighten the actuator fasteners so as to allow this movement. After the mounting hardware

is secure, check the actuator/switch engagement for misalignment and binding.

IMPORTANT: A safety switch must be installed in a manner which discourages

tampering or defeat. Mount each switch to prevent bypassing of the switching

function at the wiring chamber. A switch and its actuator must never be used as a

mechanical stop.

Manual Release for Spring Lock Models

Models with spring lock/solenoid unlock may be unlocked manually by rotating the unlock

mechanism, using an M3 Allen wrench (not supplied). First loosen the security screw

(see dimension drawing of switch, page 10), then turn the unlock mechanism in either

direction to the

position.

IMPORTANT: After the switch is installed, check to be certain that the unlock

mechanism is in the

position, and that the security screw is tight and covered with

tamper-resistant lacquer (user-supplied).

Install

Tamper-Proof

Screw

Figure 1. Horizontal actuator head position

(as received from the factory):

Install tamper-proof screw.

Install

Tamper-Proof

Screw

Figure . Vertical actuator head position:

Install tamper-proof screw.

0°

1.

2.

270°

90°

Holding

Clamp

180°

Pull Out

Figure 4. Actuator head rotation

2

1

3

4

Figure 2. To change actuator head

orientation