Maintenance/checkout, Specifications, Repairs – Banner RP-QM90 Rope Pull Switch User Manual

Page 5

Maintenance/Checkout

At switch installation or replacement and at machine set up, a Designated Person

1

must test each switch for proper

machine shutdown response and check the switch(es) and installation for proper operation, physical damage, mounting

(looseness), and excessive environmental contamination. This must also take place on a periodic schedule determined by

the user, based on the severity of the operating environment and the frequency of switch actuations. Adjust, repair, or

replace components as needed. If inspection reveals contamination on the switch, thoroughly clean the switch and

eliminate the cause of the contamination. Replace the switch and/or appropriate components when any parts or

assemblies are damaged, broken, deformed, or badly worn; or if the electrical/mechanical specifications (for the

environment and operating conditions) have been exceeded. Always test the control system for proper functioning under

machine control conditions after performing maintenance, replacing the switch, or replacing any component of the switch.

Additional items that should be included in the checkout and/or regularly scheduled maintenance of a rope pull system:

•

Check for proper rope tension and adjust as needed

•

Verify free operation (no binding) of the rope and proper tripping when the rope is pulled

•

Periodically lubricate the pulleys and other moving parts associated with the rope

•

Repair any loose or damaged hardware, worn/frayed rope (cable), missing red rope sheathing or flags/markers (if

used)

•

Remove or clean off any contamination and eliminate its cause

Repairs

Contact Banner Engineering for troubleshooting of this device. Do not attempt any repairs to this Banner device; it

contains no field-replaceable components. If the device or a device component is determined to be defective by a

Banner Applications Engineer, they will advise you of Banner's RMA (Return Merchandise Authorization) procedure.

Important: If instructed to return the device, pack it with care. Damage that occurs in return shipping

is not covered by warranty.

Specifications

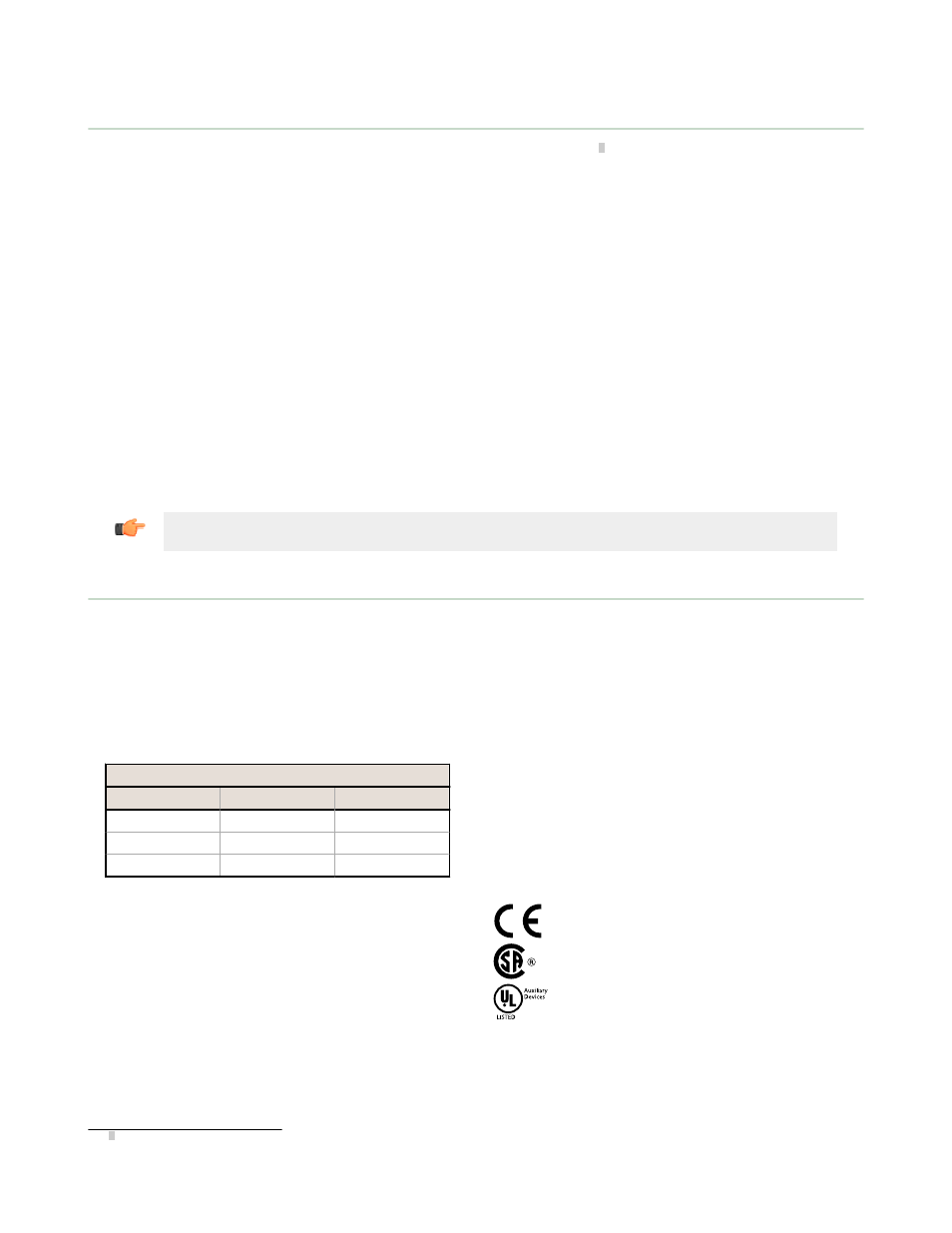

Contact Rating

10 A at 24 V ac

10 A at 110 V ac

6 A at 230 V ac

6 A at 24 V dc

2.5 kV max. transient tolerance

NEMA A300 P300

European Rating

Utilization categories: AC15 and DC13

Ui = 500 V ac; Ith = 10 A

40-60 Hz

Ue (V)

Ie/AC-15 (A)

Ie/DC-13 (A)

24

10

6

110

10

1

230

6

0.4

Contact Material

Silver-nickel allow

Maximum Switching Speed

50 operations per minute

Recommended Rope Size

4 mm diameter steel rope

Maximum Rope Pull Length

100 m (330 ft); equal lengths up to 50 m (165 ft) on either side of

switch

Short Circuit Protection

10 amp Slow Blow, 15 amp Fast Blow. Recommended external

fusing or overload protection.

Mechanical Life

1 million operations

Wire Connections

Screw terminals with pressure plates accept the following wire sizes

–

Stranded and solid: 20 AWG (0.5 mm2) to 16 AWG (1.5 mm2) for

one wire

Stranded: 20 AWG (0.5 mm2) to 18 AWG (1.0 mm2) for two wires

Cable Entry

M20 x 1.5 threaded entrance. Adapter supplied to convert M20 x

1.5 to ½"-14 NPST threaded entrance

Construction

Aluminum alloy die-cast

Environmental Rating

IEC IP65

Operating Conditions

Temperature: –30 °C to 80 °C (–22 °F to 176 °F)

Weight

3.8 Kg (8.4 lbs)

Certifications

1 A Designated Person is identified in writing by the employer as being appropriately trained to perform a specified checkout procedure.

RP-QM90 Series Rope Pull Switches

P/N 62086 Rev. D

www.bannerengineering.com - tel: 763-544-3164

5