Electrical installation – Banner RP-QM90 Rope Pull Switch User Manual

Page 4

All hardware is supplied by the user. The switch mounting holes are on a standard limit switch mounting pattern of 30 x 60

millimeters, and accept M5 (#10) hardware. Wire rope and associated hardware may be ordered separately; see

Accessories.

Installation Procedure

Rope Pull

or Break Position –

Not Ready for Operation

Proper Tension for

Operation

Figure 5. Correct Rope Tension Indicator

1. Mount the switch securely on a solid, stationary surface,

approximately in the center of the rope span.

2. Fasten an eye bolt at the far ends of the rope span, up to 50 m

(165 ft) from the switch. The anchor for the eye bolts also must be

solid and stationary, to withstand the constant tension of the rope.

3. Assemble the rope, as shown. Keep the rope’s PVC cover intact

along its complete length.

4. Use pulleys (recommended) or eye bolts at each support point. If

tensioning spring #1 is used, the span between pulleys may not

exceed 2 m (6.5 ft). If tensioning spring #2 is used, the span

between pulleys may not exceed 2.5 m (8 ft).

5. Apply tension to the rope using the turnbuckles on both sides of

the switch actuator. Apply tension until both springs are stretched

equally and the switch actuator is perpendicular to the switch

housing. (Contacts 11–12 will close and contacts 23–24 will remain

open.)

6. Pull hard on the rope and reset the latch several times. If contacts

11–12 remain open following the reset, further tighten the

turnbuckle, until the contacts close.

7. Repeat step 6 until contacts 11–12 remain closed for the Run

condition

Electrical Installation

Access to the Wiring Chamber. The wiring chamber is accessed via a cover plate (remove four screws). A conduit

adapter is supplied to convert the 20 millimeter threaded entrance to 1/2" NPT. An accessory cable gland which fits the

metric thread is also available.

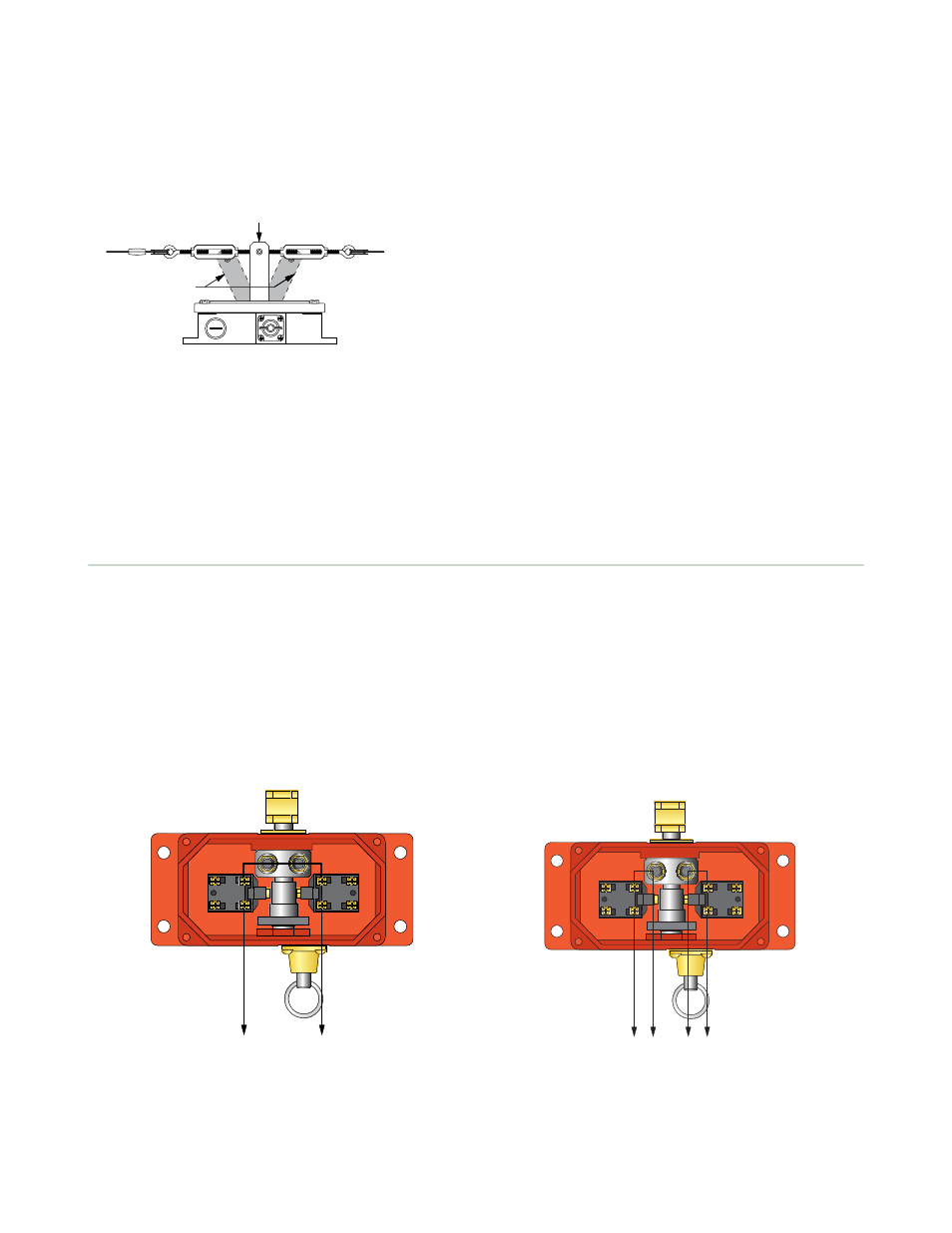

Wiring. Because the model RP-QM90F-100L has redundant pairs of safety contacts, this switch may be wired for either

single-channel or dual-channel output to a safety device. Monitor contacts, in either case, may be wired as desired to an

external alarm device. Wire the two switch contacts in series.

Single-Channel Output. Jumper the two pairs of safety contacts 11–12 and wire together to the input of a safety device

Dual-Channel Output. No jumpering is required between the two pairs of safety contacts 11–12. Wire them

independently to two safety device inputs.

11

12

23

24

11

12

23

24

Jumper

To Single-Channel

Safety Device

Figure 6. Single-Channel Safety Device

11

12

23

24

11

12

23

24

Ch 1

Ch 2

To Dual-Channel

Safety Device

Figure 7. Dual-Channel Safety Device

RP-QM90 Series Rope Pull Switches

4

www.bannerengineering.com - tel: 763-544-3164

P/N 62086 Rev. D