Mechanical installation – Banner RP-QM90 Rope Pull Switch User Manual

Page 3

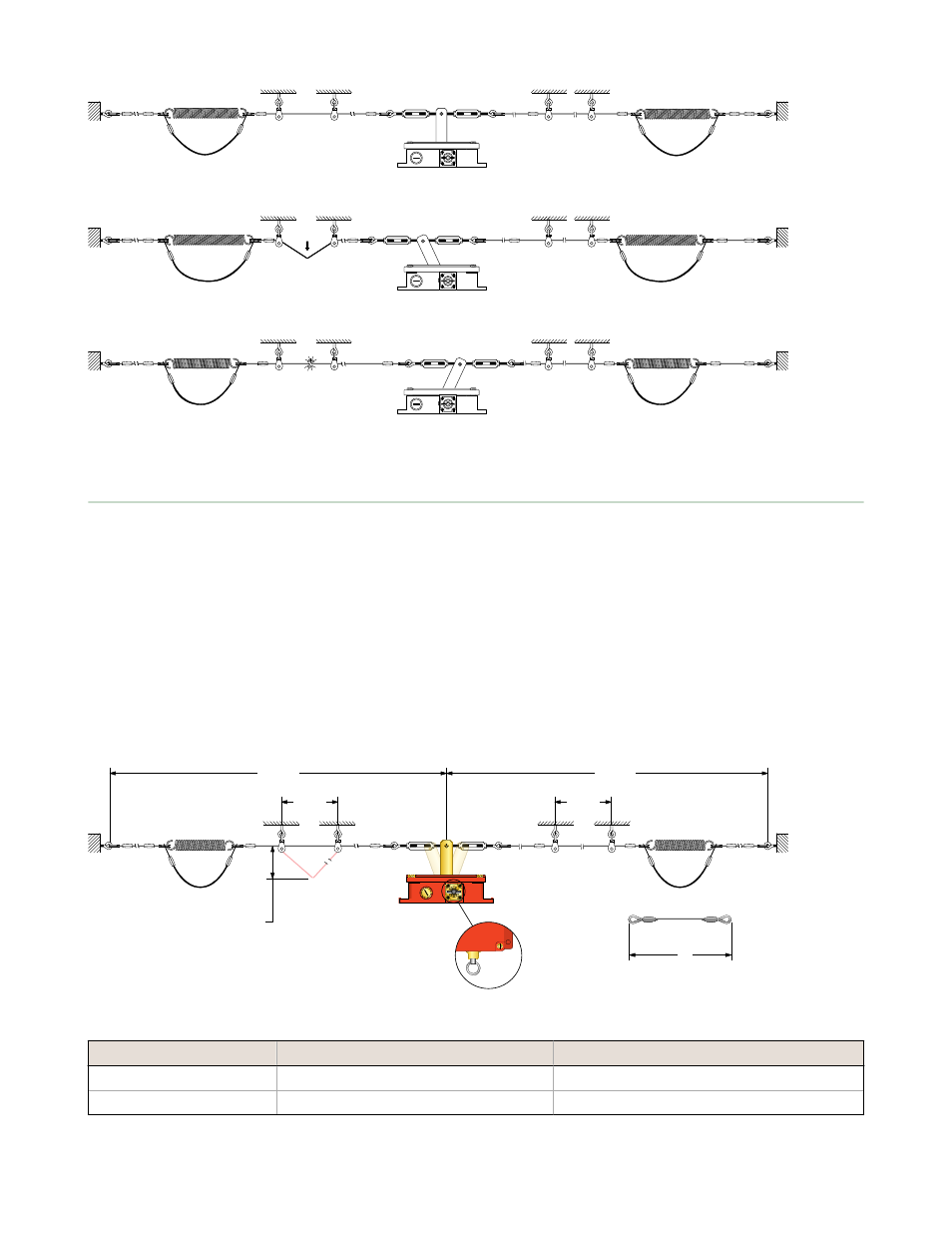

Figure 1. Run Position: Proper Rope Tension

Figure 2. Rope Pulled: Contact Pairs 11-12 Open

Figure 3. Rope Break or Slack: Contact Pairs 11-12 Open

Mechanical Installation

Installation Guidelines

•

The rope should be easily accessible and visible along its entire length. Markers or flags may be fixed on the rope

to increase its visibility

•

Mounting points, including support points, must be rigid and allow sufficient space around the rope to allow easy

access

•

The rope should be free of friction at all supports. Pulleys are recommended

•

The rope may not be routed around a corner, for this model.

•

Never run rope through conduit or other tubing

•

Never attach weights to the rope

•

Temperature affects rope tension. The wire rope expands (lengthens) when temperature increases, and contracts

(shrinks) when temperature decreases. Significant temperature variations require frequent checks of the tension

adjustment

•

Do not exceed the maximum specified total rope length. Banner offers models for other spans; contact Banner

Engineering or visit

www.bannerengineering.com

for model selection

11

23

11

12

23

24

Pull ring

to reset

L2

L2

L6

Spring breakage

protector cable

400 mm (16") max.

for Actuation of Switch

50 m (165')

max.

50 m (165')

max.

NOTE:

Force to actuate must

not exceed 200 N (45 lbf)

Figure 4. Assembly of Rope and Hardware

Springs Used

Max. Span Between Pulleys (L2)

Spring Breakage Protector Cable Length (L6)

Tensioning Spring #1

1 m to 2 m (3 ft to 6.5 ft)

380 mm to 410 mm (15.0 inches to 16.1 inches)

Tensioning Spring #2

2 m to 2.5 m (6.5 ft to 8 ft)

310 mm to 320 mm (12.2 inches to 12.6 inches)

RP-QM90 Series Rope Pull Switches

P/N 62086 Rev. D

www.bannerengineering.com - tel: 763-544-3164

3