Mechanical installation – Banner Compact Metal Style Safety Interlock Switches User Manual

Page 3

P/N 50159 Rev. F

3

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Machine Safety Switch: SI-LM40 Series Limit Switch Style

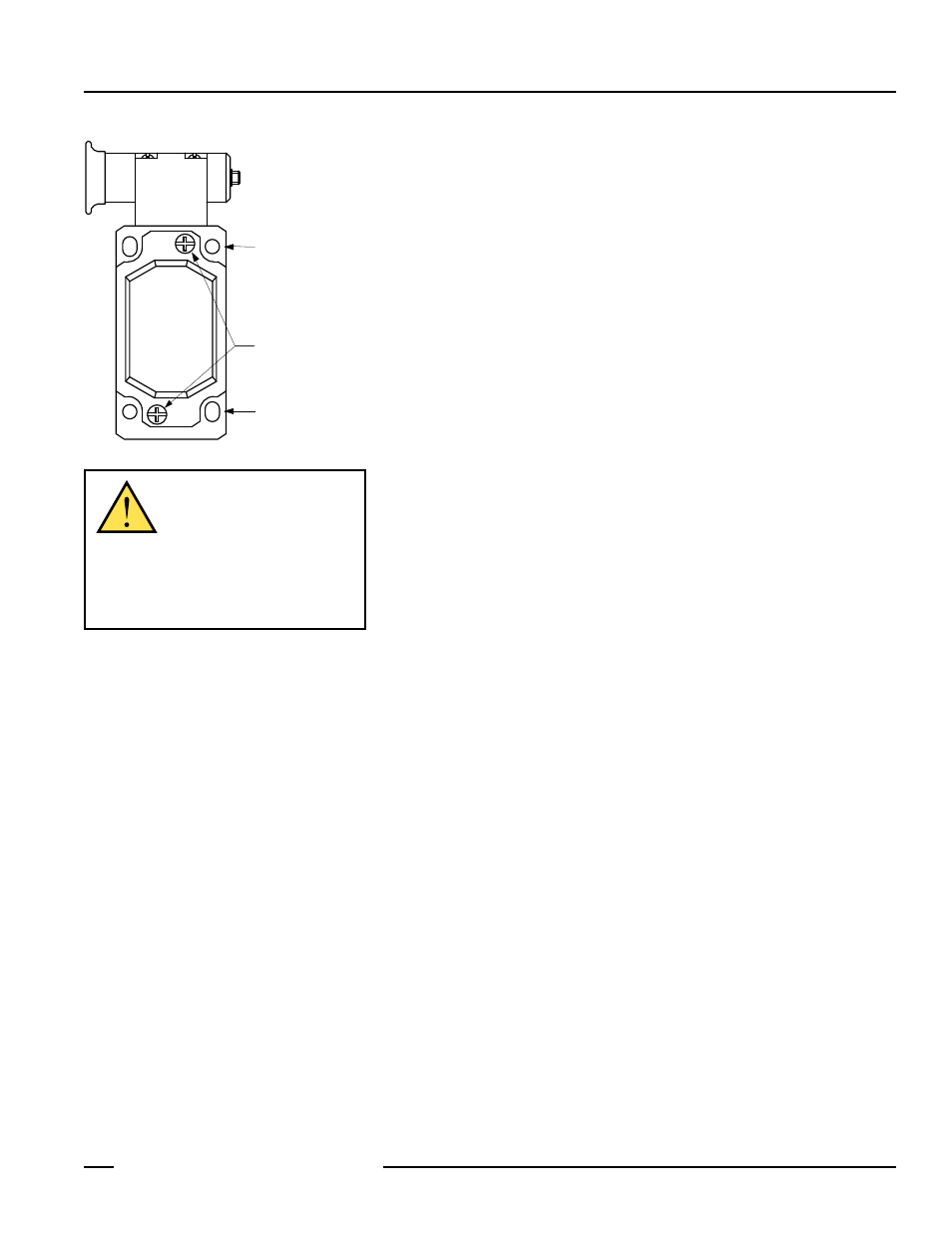

Round (5 mm) holes

for permanent

installation (2X)

Slotted holes for initial

alignment only (2X)

Remove to access

wiring chamber (2X)

Mechanical Installation

All mounting hardware is supplied by the user. The fasteners must be of sufficient

strength to guard against incidental breakage. Use of permanent fasteners or

locking hardware is recommended to prevent loosening or displacement of the

actuator and switch body.

Note: The slotted holes in the switch body must ONLY be used for alignment

during installation (see Figure 1). The round 5 mm holes (only) must be used for

permanent mounting to prevent loosening or displacement of the actuator and the

switch body. Only M5 (#10) screws (customer supplied), should be used.

There are four holes on a mounting pattern of 30 x 60 mm. The actuator has four

M4 tapped mounting holes on a 26 mm (1.02") square pattern (see dimensions on

page 7).

Position the switch, with its actuator fully engaged, in the mounting location and

mark the mounting holes. Drill the required holes and fasten the switch body and

the actuator in place. After the mounting hardware is secure, check the actuator/

switch engagement for misalignment and binding.

The actuator is spring-loaded to allow positive pressure to be applied when the

guard is closed. However, the switch must never serve as the mechanical end stop

for a guard door or gate. Positive pressure for the actuator engagement is desirable,

because only 1 mm (0.04") of actuator travel from the point of full engagement is

required to open the safety contact.

Important:

1. A safety switch must be installed in a manner which discourages

tampering or defeat. Mount each switch to prevent bypassing of the

switching function at the terminal chamber.

2. A switch and its actuator must never be used as a mechanical stop.

3. Ensure proper placement of gasket when rotating head. Failure to do so

will reduce the environmental rating.

WARNING ... It must not be possible

for personnel to reach any hazard

point through an opened guard (or

any opening) before hazardous machine motion has

completely stopped. Please reference OSHA CFR

1910.217 and ANSI B11 standards (see page 2) for

information on determining safety distances and safe

opening sizes for your guarding devices.