Wiring the modules – Rockwell Automation 1790P-4R0 CompactBlock LDX I/O RTD/Resistance Input Module User Manual

Page 25

Publication 1790-UM002A-EN-P

Installation and Wiring 2-13

To insure that the lead values match as closely as possible:

•

Keep lead resistance as small as possible

.

•

Use quality cable that has a small tolerance impedance rating.

•

Use a heavy-gauge lead wire which has less resistance per foot.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wiring the Modules

After the module is properly installed, follow the wiring procedure below

and the RTD and potentiometer wiring diagrams on pages 2-15 through

2-16. To ensure proper operation and high immunity to electrical noise,

always use Belden shielded, twisted-pair or equivalent wire.

Table 2.6 Wire Size and Terminal Screw Torque

Wire Type

Wire Size

Terminal Screw

Torque

Retaining Screw

Torque

Solid

Cu-90°C (194°F)

#14 to #22 AWG

0.68 Nm (6 in-lbs)

0.46 Nm (4.1 in-lbs)

Stranded Cu-90°C (194°F)

#16 to #22 AWG

0.68 Nm (6 in-lbs)

0.46 Nm (4.1 in-lbs)

ATTENTION

ÿ

To prevent shock hazard, care should be taken when

wiring the module to analog signal sources. Before

wiring any module, disconnect power from the system

power supply and from any other source to the module.

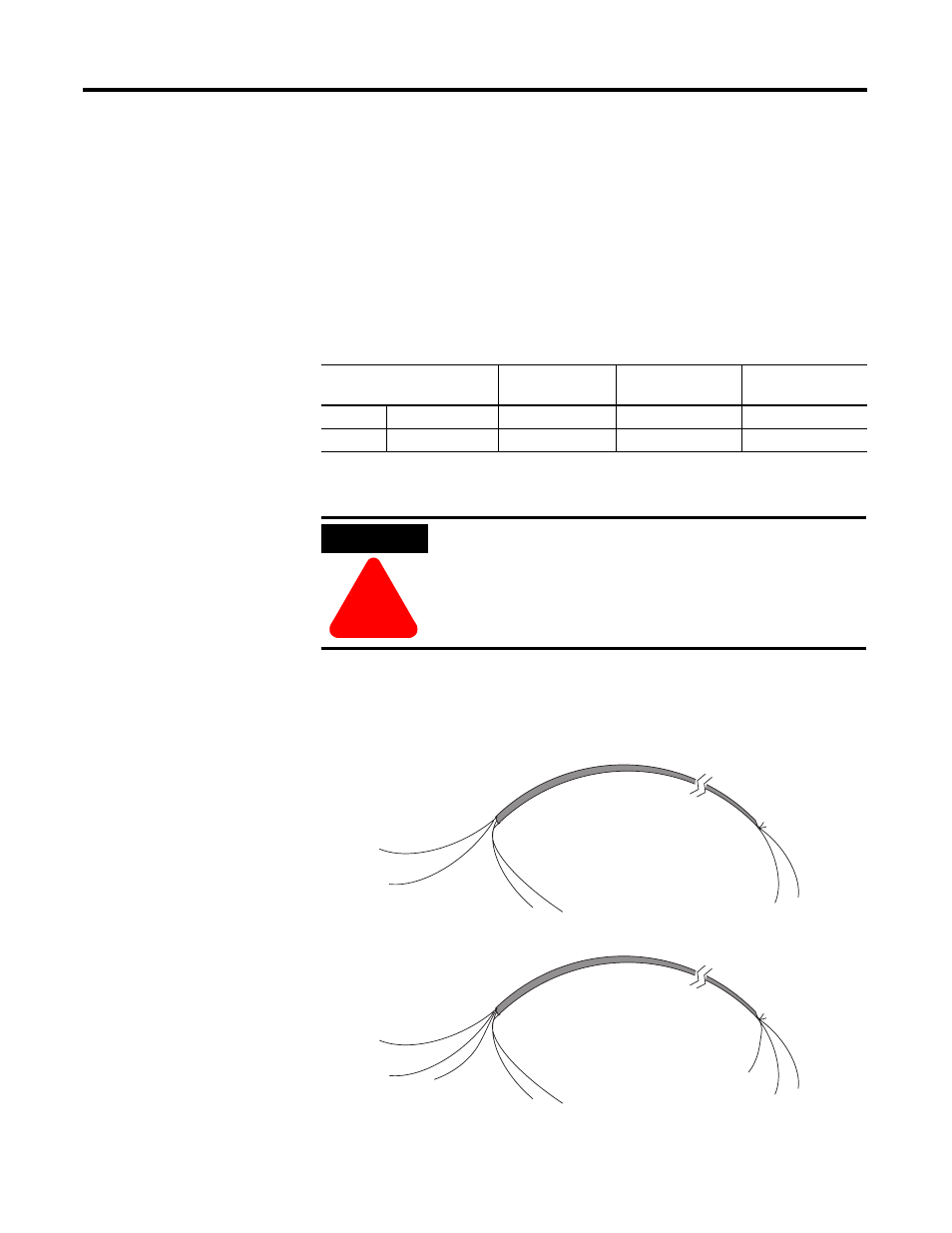

cable

signal wire

signal wire

drain wire

foil shield

signal wire

signal wire

Cut foil shield

and drain wire

cable

signal wire

signal wire

drain wire

foil shield

signal wires (3)

Cut foil shield

and drain wire

signal wire

43250