Rtd wiring considerations – Rockwell Automation 1790P-4R0 CompactBlock LDX I/O RTD/Resistance Input Module User Manual

Page 24

Publication 1790-UM002A-EN-P

2-12 Installation and Wiring

RTD Wiring Considerations

Because the operating principle of the RTD module is based on the

measurement of resistance, take special care when selecting your input

cable. For 2-wire or 3-wire configurations, select a cable that has a

consistent impedance throughout its entire length. Cable specifications are

noted below.

When using a 3-wire configuration, the module compensates for

resistance error due to lead wire length. For example, in a 3-wire

configuration, the module reads the resistance due to the length of one of

the wires and assumes that the resistance of the other wire is equal. If the

resistances of the individual lead wires are much different, an error may

exist. The closer the resistance values are to each other, the greater the

amount of error that is eliminated.

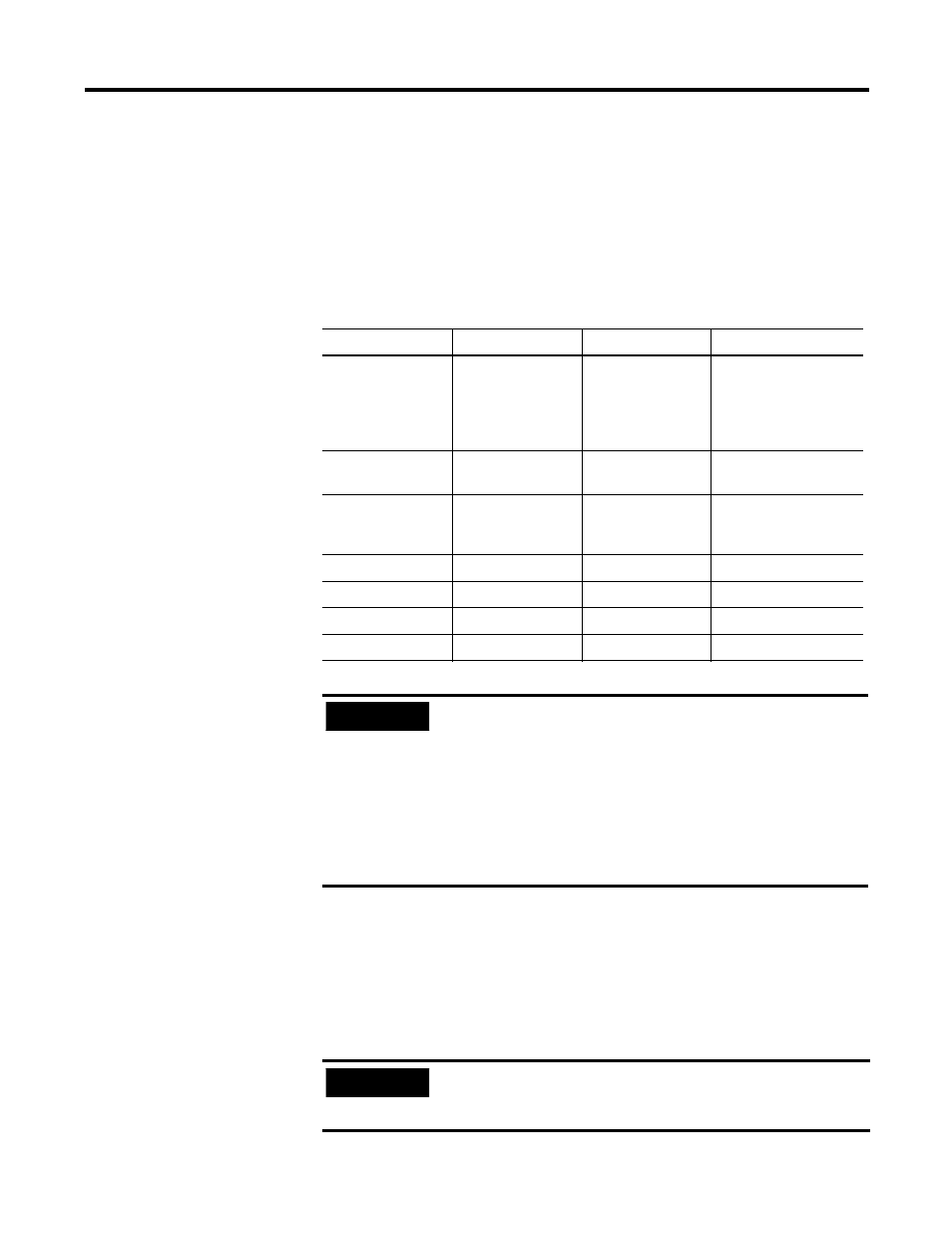

Table 2.5 Cable Specifications

Description

Belden #9501

Belden #9533

Belden #83503

When used?

For 2-wire RTDs and

potentiometers

For 3-wire RTDs and

potentiometers.

Short runs less than

100 feet and normal

humidity levels.

For 3-wire RTDs and

potentiometers. Long

runs greater than 100

feet or high humidity

levels.

Conductors

2, #24 AWG tinned

copper (7 x 32)

3, #24 AWG tinned

copper (7 x 32)

3, #24 AWG tinned

copper (7 x 32)

Shield

Beldfoil aluminum

polyester shield with

copper drain wire

Beldfoil aluminum

polyester shield with

copper drain wire

Beldfoil aluminum

polyester shield with

tinned drain wire

Insulation

PVC

S-R PVC

Teflon

Jacket

Chrome PVC

Chrome PVC

Red Teflon

Agency Approvals

NEC Type CM

NEC Type CM

NEC Art-800, Type CMP

Temperature Rating

80°C

80°C

200°C

IMPORTANT

The RTD module requires three wires to compensate for

lead resistance error. We recommend that you do not

use 2-wire RTDs if long cable runs are required, as it

reduces the accuracy of the system. However, if a

two-wire configuration is required, reduce the effect of

the lead wire resistance by using a lower gauge wire for

the cable (for example, use AWG #16 instead of AWG

#24). The module’s terminal block accepts two AWG #14

gauge wires.

IMPORTANT

To ensure temperature or resistance value accuracy, the

resistance difference of the cable lead wires must be

equal to or less than 0.01

Ω .