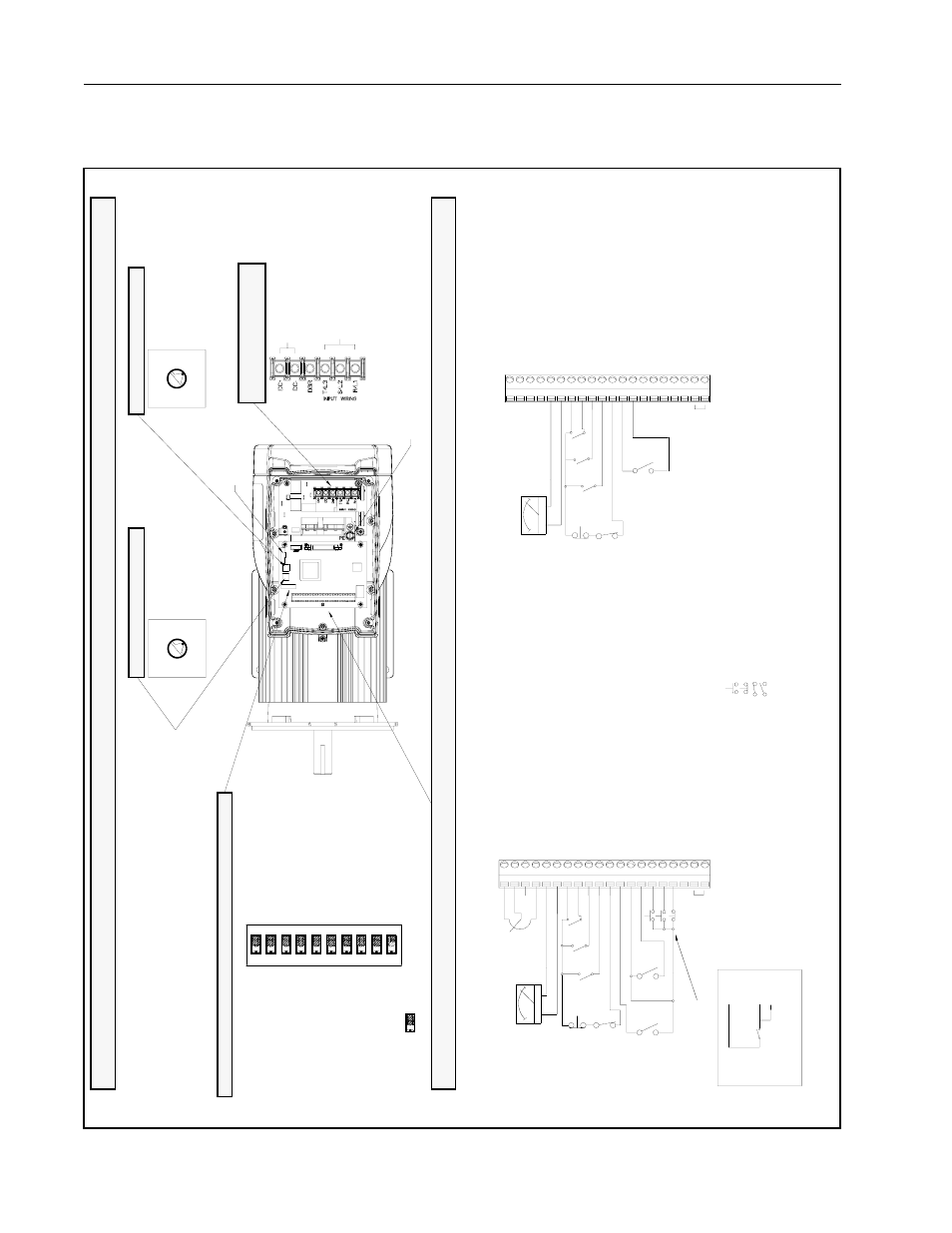

Installation overview, Control sign al terminal block conn ection s, Selectors an d con nectors – Rockwell Automation 1329I Integrated AC Drive/Motor, Series A User Manual

Page 6: Lo ca l op erato r co ntrol un it sta nda rd un it

Checklist-2

Installation Checklist

1329I-5.0 Integrated Drive/Motor — January, 1999

Installation Overview

Accel

/ De

cel

Swit

ch

Max

Sp

ee

d

Swit

ch

S

e

tu

p

DIP S

witch

T

op V

iew o

f Un

it

With

Cove

r Re

move

d

Di

spl

a

y Boar

d

- DBR (Do

Not W

ire

)

Co

nn

ec

tio

n

s

AC I

npu

t Po

we

r

DC Bu

s (Do

Not

Wi

re)

A

C

Inp

u

ts

➋

1

2

RP

M /

%Lo

ad Disp

lay

1

0

Sp

ee

d Pr

es

et 0

11 Fu

nct

ion

L

o

ss

13

2

4

V

D

C

14

F

o

rw

a

rd/

Re

ve

rse

15 Reset

16

S

ta

rt

1

8

24

DC Co

mmo

n

1

9

N.O

. Rela

y

20 Re

lay Com

m

on

=

N.O. Mom

entar

y

Co

ntact

=

M

a

in

tained

Con

tact -

Open

=

M

a

in

tained

Con

tact -

Clos

ed

=

N.C

. Mo

men

tary C

onta

c

t

Main

ta

in

ed 2-

Wir

e

➊

Star

t

17

16

%L

O

A

D

RP

M

13

RE

V

+ -

FWD

➋

5K

9 Sp

eed P

reset

1

5

0

to

1

0

V

Ou

tp

ut

7

24V

DC

8

S

p

ee

d Pr

ese

t 2

2

0 to

1

0

V

Sp

d Ref

In

pu

t

3

4

t

o

20

m

A

Sp

d

R

e

f

In

p

u

t

+

10V

DC

1 1

0

Vo

lt

Re

fere

nce

G

round

M

o

m

e

nt

ar

y 3

-Wi

re

St

a

rt

Min S

pd fr

om T

e

rm

inal B

lock

Input

s

= D

e

fa

u

lt

Se

tt

in

g

(O

F

F

Po

s

itio

n

)

3 H

z

M

inimu

m S

peed

Re

verse

Enab

led

C

oast

-to-R

est S

top

8

6

7

An

alog

Spd R

e

f fr

om T

e

rmi

nal B

lock

➊

Spd R

e

f fr

om O

pera

tor C

ontro

ls

Relay

O

u

tput C

ontro

l: Run

n

ing

R

un O

n

Po

wer U

p

D

isabl

ed

Va

riable

Tor

que C

u

rve

Auto

Res

tart D

isabl

ed

4

5

3

2

N

1

O

9 10

(N

ot U

sed)

(N

ot U

sed)

➊

RP

M

%L

OA

D

+ -

Lo

ca

l

Op

erato

r Co

ntrol

Un

it

Sta

nda

rd Un

it

(0

to

M

a

x

Spd

)

0

= 1 s

e

c

ac

ce

l /

5 se

c d

e

c

e

l

1 =

5

se

c (

D

efa

u

lt

)

2 =

1

0

s

e

c

3 =

1

5

s

e

c

4 =

2

0

s

e

c

5 =

3

0

s

e

c

6 =

6

0

s

e

c

7 = 90

sec

6

2

3

45

1

0

7

Conne

ct

or

➊

S

lide

swit

ch

2

is

use

d

on

ly

wit

h

loc

a

l op

erat

or

co

nt

ro

l un

it

s.

C

onnec

t t

o

e

x

te

rnal

de

v

ice

su

c

h

a

s

PL

C

in

put

.

input

.

C

onnec

t t

o

e

x

te

rnal

dev

ice su

ch as P

L

C

3

45

1

2

7

0

6

0

=

15

00 RPM (50 Hz)

7

=

36

00

RPM

(120

Hz

)

6

=

33

00

RPM

(110

Hz

)

5

=

30

00

RPM

(100

Hz

)

4

=

27

00 RPM (90 Hz)

3

=

24

00 RPM (80 Hz)

2

=

21

00 RPM (70 Hz)

1

=

18

00 RPM (60 Hz)

(D

e

fau

lt)

Ru

n

O

n

P

o

we

r Up

E

n

ab

le

d

R

e

lay

O

u

tp

ut Co

ntrol

: Fau

lted

Au

to Re

start

Enab

led

Cons

tant

Torqu

e

Cu

rve

Ram

p

-to-

Rest

Stop

R

eve

rse D

isabl

ed (R

ever

se Lo

ckou

t)

6 C

o

m

m

o

n

➊

Control

Sign

al

Terminal Block

Conn

ection

s

Commo

n

4

1

2

RPM

/

%

Loa

d Disp

lay

10

S

p

e

ed P

rese

t 0

11

F

u

nct

io

n

Lo

ss

13

24V

DC

1

4

F

o

rw

ar

d/

R

e

ve

rs

e

15 Reset

16

St

art

18

24 DC Co

mmon

1

9

N.

O.

R

e

lay

2

0

Rel

a

y Comm

on

9 Sp

eed

Prese

t 1

5 0 to 10

V Ou

tpu

t

7 24

V DC

8 Sp

ee

d Pr

es

et 2

2 0 to 10

V Sp

d Re

f Inp

u

t

3

4

to

20

m

A

Sp

d

Re

f

In

pu

t

1 10

Vol

t Re

fe

re

nce

6

Co

mmo

n

Co

mmo

n

4

St

op

17

St

op

17

➊

Selectors

an

d Con

nectors

The j

u

mp

er bet

ween

term

inals

7 an

d 11

mus

t be r

e

mov

ed w

hen w

iring

the

Func

tion L

oss i

nput.

See S

ectio

n 7.1

for more i

n

formation

.

An ex

terna

l 0 to

10 v

o

lt or

4 to 2

0

m

A

spee

d refe

rence

sou

rce c

an be

conn

ected

.

See S

ectio

n 7.5

.3 for

m

o

re

info

m

a

tio

n.

T

he jum

per

betw

een te

rmin

als 7

and 1

1

m

ust b

e

rem

oved

whe

n

wir

ing th

e

F

unctio

n Los

s inp

u

t. Se

e Se

ction

7.1

fo

r m

o

re inf

o

rm

a

tion.