Rockwell Automation 1329I Integrated AC Drive/Motor, Series A User Manual

Page 38

8-4

Step 8 - Verify the Setup and Adjust Switches if Required

1329I-5.0 Integrated Drive/Motor — January, 1999

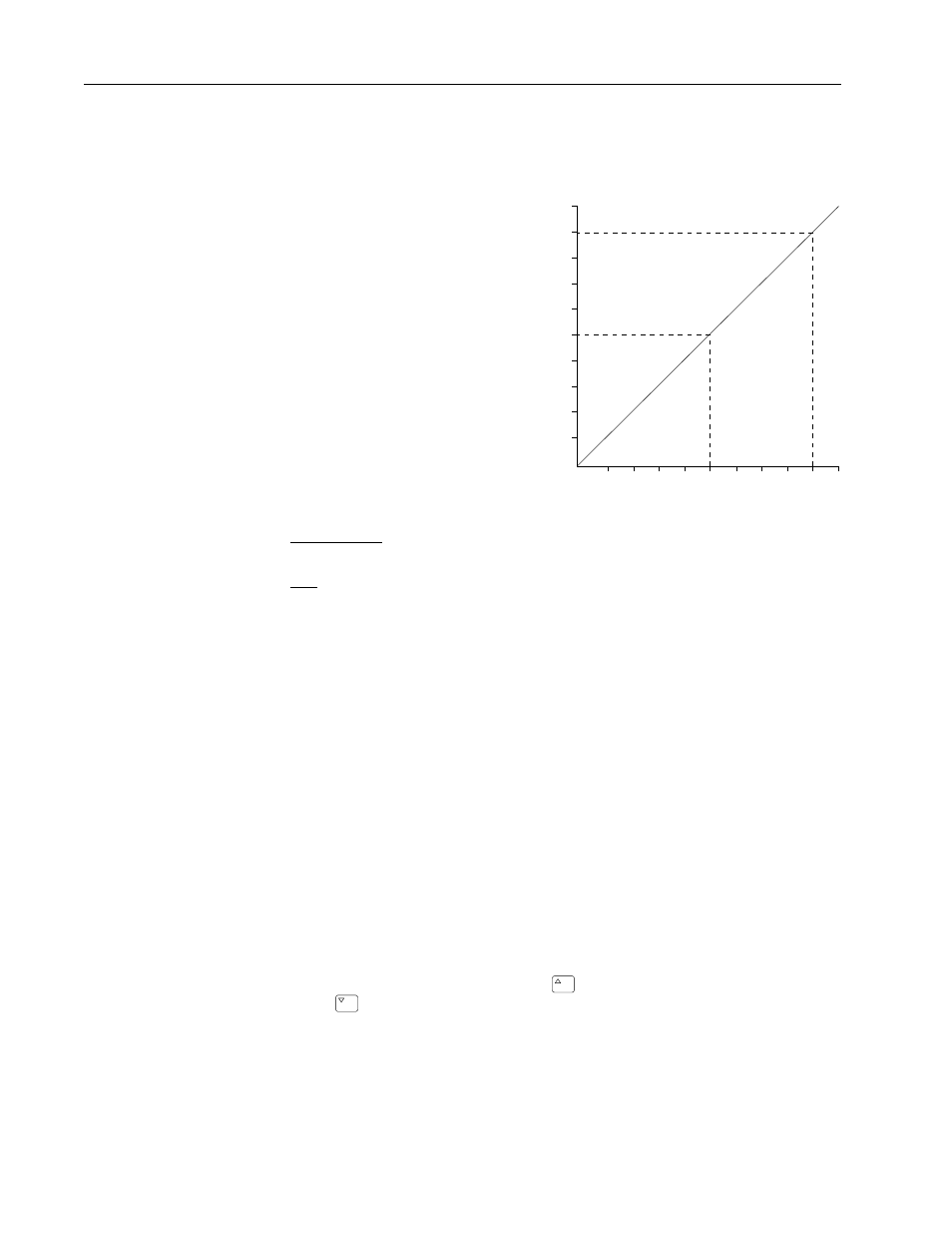

Note that if the operator speed reference setting is less than the maximum speed value,

the acceleration / deceleration ramp time is proportionately less than the acceleration /

deceleration setting.

To adjust the acceleration / deceleration time:

1. To increase the acceleration / deceleration time, turn the accel / decel rotary switch to a

higher position number.

-or-

To decrease the acceleration / deceleration time, turn the accel / decel rotary switch to a

lower position number.

2. Connect the display board ribbon cable and replace the cover. Verify that all four

cover screws are in place and tightened.

3. Apply AC input power.

4. Set the desired operating speed.

5. Standard units: Use the speed potentiometer or other user-supplied external

speed reference device.

6. Local operator control units: Use the

key to increase the speed reference

and the

key to decrease the speed reference.

7. Repeat the adjustment procedure until the desired acceleration / deceleration time

is obtained. Note that changes to the acceleration / deceleration time are recog-

nized only while the drive is stopped.

Important:

If speed is erratic or not as expected, verify that only one of the speed

reference inputs (0 to 10 VDC or 4 to mA) has been wired.

TIME

15 Sec

30 Sec

1800 RPM

900 RPM

SPEED

Example

Assume:

Max Speed = 1800 RPM

Operating Speed = 900 RPM

Accel/Decel Time Setting = 30 Seconds

Use this formula:

x Accel/Decel Time Setting = Time to Operating Speed

x 30 = 15

It will take 15 seconds to ramp from stop to 900 RPM.

Operating Speed

Max Speed

900

1800