Rockwell Automation 1441-DYN25-MBAL Balancing Extension Module for the Dynamix 2500 User Manual

Page 25

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

25

Balancing Extension Module Chapter 2

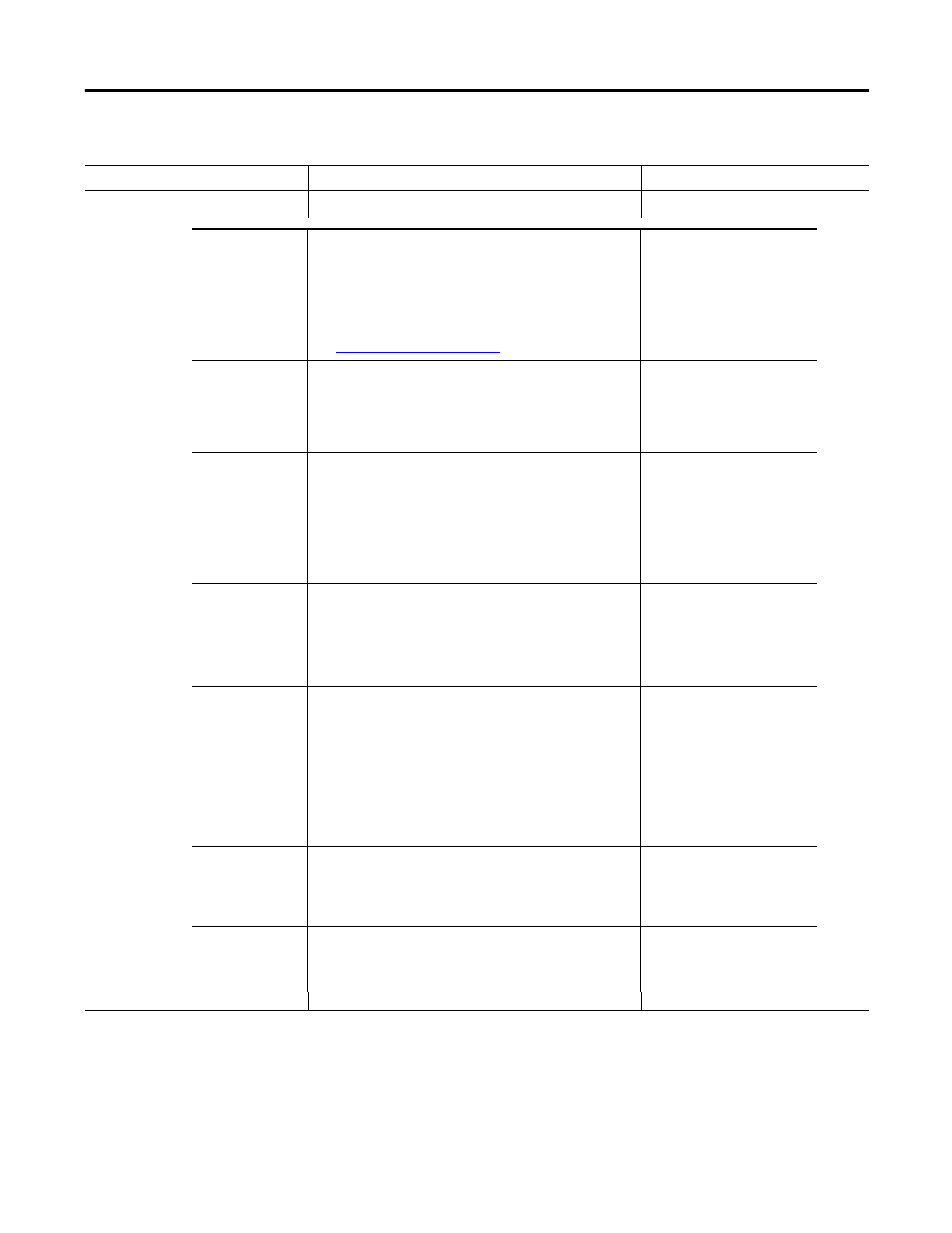

Plane (x)

Sets the plane for which the settings below apply.

Two plane get two sets of the following attributes/parameters

(settings)

1

2

Table 2 - Balance Extension Module Parameters

Parameter Description

Value

Input Chan

The input channel required for the measurement.

Select channel X for single-plane balancing, with the

transducer connected to the data collector’s Connection A.

For two-plane balancing with two transducers, you set one

plane’s transducer as channel X, the other plane’s transducer as

channel Y.

Two Plane Balancing on page 45

for more information.

X (default) on connector A only

Y, on Connector B

Coupling

The type of coupling to be applied to the measurement.

• AC, Acquires the input signal from a buffered output

(external) device. Power is not applied to the transducer.

• ICP, Applies DC to the charge amplified transducer signal

and couples the dynamic signal to the input channel.

AC

ICP

(default)

Sensitivity

The sensitivity of the transducer. Sensitivity is set as mV/EU,

where EU is the base engineering unit of the transducer.

Use the keypad to enter the transducer sensitivity in millivolts

(mv) per Engineering Unit (EU). 100 mV/EU is used for most

acceleration transducers, 200 mV/EU for most non-contact

displacement transducers, and 1000 mV/EU if the input is volts

and the scales is to be read directly. The default setting is 100

mV/EU.

0.010 to 1000 mV/EU

A 100 m V/G accelerometer

would be set as 100 m V/EU

Input Range

Select the signal input range between Autorange and a fixed

range in transducer units in a 1 - 2 - 5 sequence. The available

fixed values vary depending on the transducer type being used.

If a fixed range is selected and the data collector detects an

over range, it automatically selects the next higher range until

it does not over range.

Autoranging

Type

Select the appropriate weight position type,

For a rotor without vanes or blades, set Type to Continuous.

Continuous specifies that weights may be placed at any

placement position on the balance plane.

Fixed is known also as vector splitting. It works with Number of

Positions and Position 1 Offset fields. Fixed specifies that

weights may be placed only at designated positions, for

example, rotors having a specific weight hole pattern, or with a

specific number of fan blades.

Continuous (default)

Fixed

No. of posns

Applies to Fixed weight position measurements only.

The first position defaults to 0

°

, subsequent positions evenly

spaced.The number of positions refers to the number of rotor

components, such as blades on a fan.

3 to 360

°

Enter 0 (zero) for a rotor without

vanes or blades.

Posn 1 Offset

Applies to Fixed weight position measurements only.

Enter the fixed position 1 offset, from zero to 360

°

, relative to

the trigger reference.

0 to 360

°