Rockwell Automation 1503VC IntelliVAC Contactor Control Module User Manual

Page 37

Monitoring and Troubleshooting

5-5

1503-UM051D-EN-P – June 2013

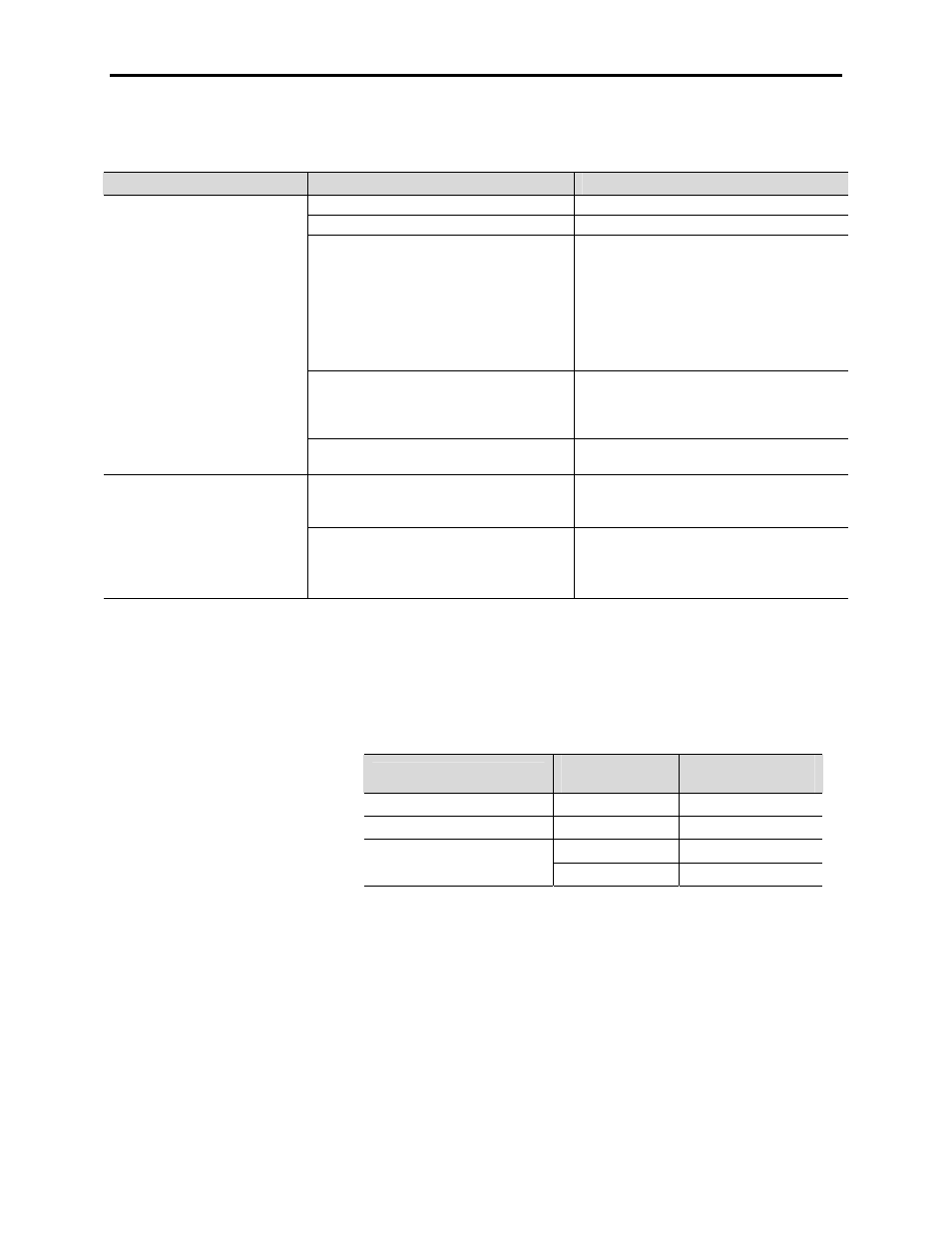

Table 5.C – Module Troubleshooting (cont.)

Problem or Trip Indicated

Indication of the following conditions

Possible Solutions

• Motor Protection activated

• Investigate and reset.

• Stop command initiated

• Verify circuit

• Module Status LED ‘Red’

• Undervoltage fault (no TDUV), control voltage

dipped below trip point. Cycle control power

to reset. Verify voltage levels are 110 to 240

VAC, 110 to 250 VDC.

• With external capacitor and TDUV feature

activated, undervoltage condition for longer

than programmed TDUV time. Undervoltage

fault activated. Cycle control power to reset.

• Module Status LED ‘Green’ and Contactor

Status LED ‘Red Flash 2’ (Series B only)

• Contactor Status feedback between Terminals

11 and 12 on the IntelliVAC has closed. The

IntelliVAC will de-energize the coil, thinking

the contactor has opened for other reasons.

Contactor opens during operation

• Both status LEDs ‘Off’

• Check control voltage and internal control

fuse. (Refer to Figure 4.1 for location.)

• Module Status LED ‘Red’ and Contactor

Status LED ‘Yellow’ (Series A, with firmware

2.001 or newer)

• Check control power to ensure that it has not

dipped below minimum (see Table 5.D).

Contactor does not open

(mechanical latch only)

• Module Status LED ‘Yellow’ and Contactor

Status LED ‘Yellow’ (Series B, with firmware

2.001 or newer)

• Trip mechanism is damaged. Inspect and

replace if needed.

• Check for loose connections in the control

circuit.

Refer to Tables 5.A or 5.B for definition of Module LED states.

Table 5.D – Minimum IntelliVAC Operational Supply Voltages

Voltage Level

Contactor Rating

(Amps)

Minimum Voltage

(VAC, 47 to 63 Hz)

Pick-Up

400/800

95

Drop-Out

400/800

75

400

70

Trip (Mechanical Latch)

800

80