5 - troubleshooting, Troubleshooting and contactor coil resistance, Chapter 5 – Rockwell Automation 1502 Medium Voltage 400A Contactor - Series E User Manual

Page 55: Troubleshooting, Chapter

Rockwell Automation Publication 1502-UM052H-EN-P - June 2013

55

Chapter

5

Troubleshooting

Troubleshooting and

Contactor Coil Resistance

If an operating problem occurs, use the following troubleshooting chart to isolate

the cause of the failure and find corrective action. If the corrective action fails to

resolve the problem, consult your local Rockwell Automation field support

representative.

If faulty contactor coil(s) are the suspected cause of malfunction, refer to

for typical coil resistance values and check the contactor coils.

(1) Resistance values listed have a tolerance of ±10%. Refer to

for measurement points at the contactor receptacle.

(2) Supplied only with mechanical latch option.

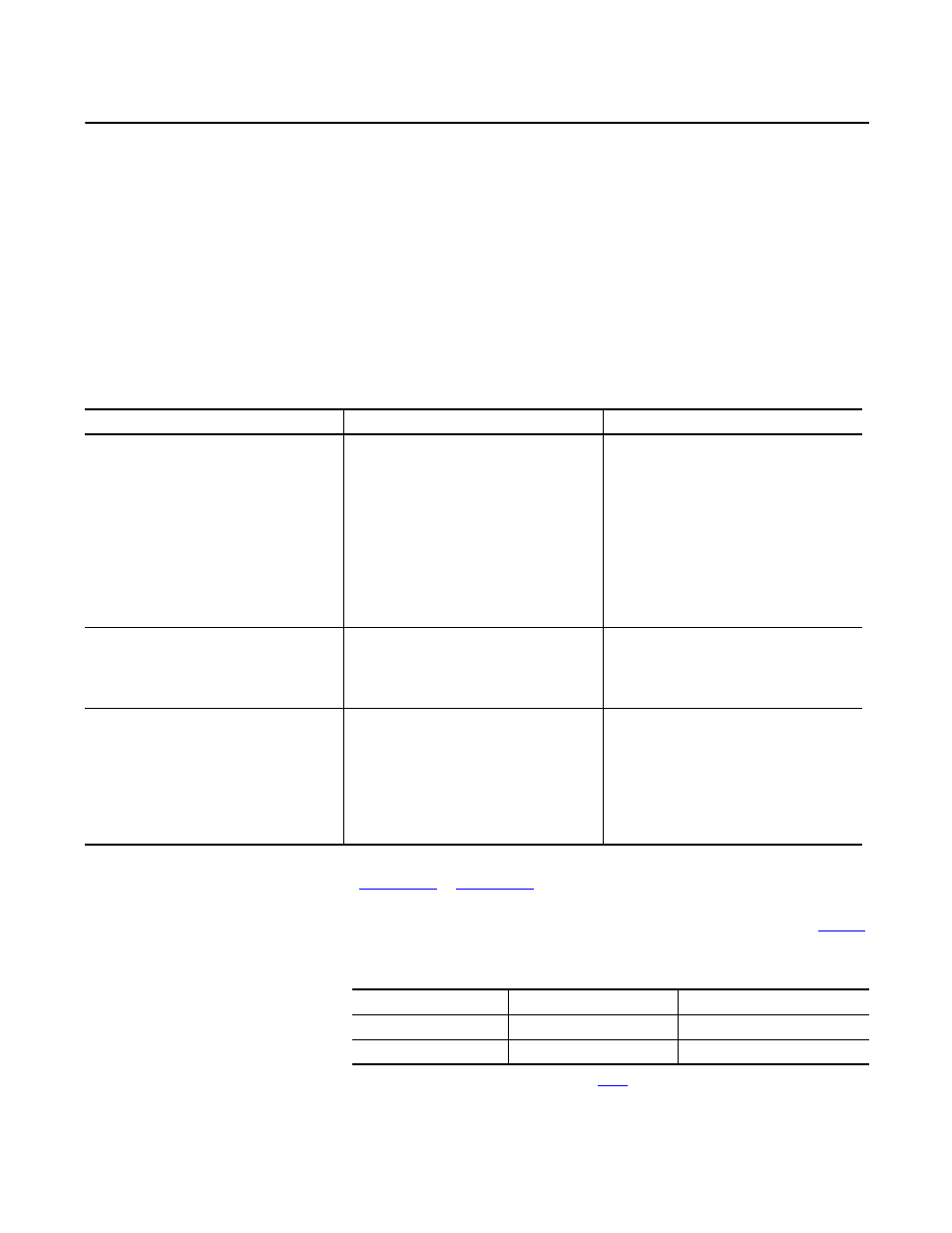

Table 6 - Troubleshooting

Symptom

Possible Cause

Actions

Contactor Chatters

(1)

• Loose connections in control circuit

• Coil leads reversed

• Control voltage too low

• Foreign material on contactor magnet

• Improper set-up of contactor auxiliary contact

assembly

• Faulty auxiliary contacts

• Faulty CR1 or CR2 interposing relay (mechanical latch

only)

• Faulty IntelliVAC or IntelliVAC Plus

• Latch not engaging

• Check all connections in control circuit for tightness

• Check wiring from the coil to the terminal block

assembly

• Measure control voltage. Refer to Contactor

Specifications for minimum pick-up voltage

• Clean magnet cores and armature

• Check set-up of contactor auxiliary contact assembly.

• Check master contact cartridges on contactor

• Ensure N.C. contact from contactor auxiliary assembly

is wired to auxiliary input on IntelliVAC or IntelliVAC

Plus

• Replace IntelliVAC or IntelliVAC Plus control module

• Check adjustment of mechanical latch

Coil Burnout

• Coil leads improperly wired

• Faulty IntelliVAC or IntelliVAC Plus control module

(2)

• Improper set-up of contactor auxiliary contact

assembly

(1)

• Control voltage too high

(2)

• Check wiring from the coil to the terminal block

assembly

• Replace IntelliVAC or IntelliVAC Plus control module

(2)

• Check set-up of contactor auxiliary contact assembly

(1)

• Check for correct control voltage

(1)

Contactor does not energize

• Loose connections in control circuit

• Damaged contactor auxiliary contacts

• Control voltage too low

• Improper set-up of contactor auxiliary contact assembly

• Faulty CR1 or CR2 interposing relay

(1)

• Faulty IntelliVAC or IntelliVAC Plus control module

(2)

• Check all connections in control circuit for tightness.

Check wiring from the coil to the terminal block

assembly

• Replace contactor auxiliary contact assembly

• Measure control voltage. Refer to Contactor

specifications for minimum pick-up voltage

• Check set-up of contactor auxiliary contact assembly

• Check CR1 and CR2 relay

(1)

• Check IntelliVAC or IntelliVAC Plus status LEDs

(2)

(1) Valid if mechanical latch contactors are controlled with electromechanical circuit only.

(2) Valid if IntelliVAC or IntelliVAC Plus control module is used (refer to

and

).

Table 7 - Typical Contactor Coil Resistance Values

Coil Part Number

Description

DC resistance (Ω)

(1)

80026-230-01

Operating Coil (each)

19.2 (9.6 x 2)

80022-067-01

(2)

Mechanical Latch Trip Coil

17.6